FORM

SECTION 7

MAINTENANCE

RENEWAL PARTS

For any required Renewal Parts, refer to “Parts Lists” shown in “Reference Instructions”, page 2.

CHECKING SYSTEM FOR LEAKS

LEAK TESTING DURING OPERATION

The refrigerant side of the system is carefully pres- sure tested and evacuated at the factory.

After the system is in operation under load, the high pressure components should be carefully leak tested with a leak detector to be sure all joints are tight.

If any leaks are indicated, they must be repaired im- mediately. Usually, leaks can be stopped by tightening flare nuts or flange bolts. However, if it is necessary to repair a welded joint, the refrigerant charge must be removed. (See “Handling Refrigerant for Dismantling and Repair”, page 53.)

CONDUCTING R-22 PRESSURE TEST

With the

lide torch or electronic leak detector can be used to detect any leaks too small to be found by the soap test.

To test with

1.With no pressure in the system, charge

2.Build up the system pressure with dry nitrogen to approximately 10 psig. To be sure that the concen- tration of refrigerant has reached all part of the sys- tem, slightly open the oil charging valve and test for the presence of refrigerant with a leak detector.

3.Test around each joint and factory weld. It is impor- tant that this test be thoroughly and carefully done, spending as much time as necessary and using a good leak detector.

4.To check for refrigerant leaks in the cooler and con- denser, open the vents in the cooler and condenser heads and test for the presence of refrigerant. If no refrigerant is present, the tubes and tube sheets may be considered tight. If refrigerant is detected at the vents, the heads must be removed, the leak located (by means of soap test or leak detector) and repaired.

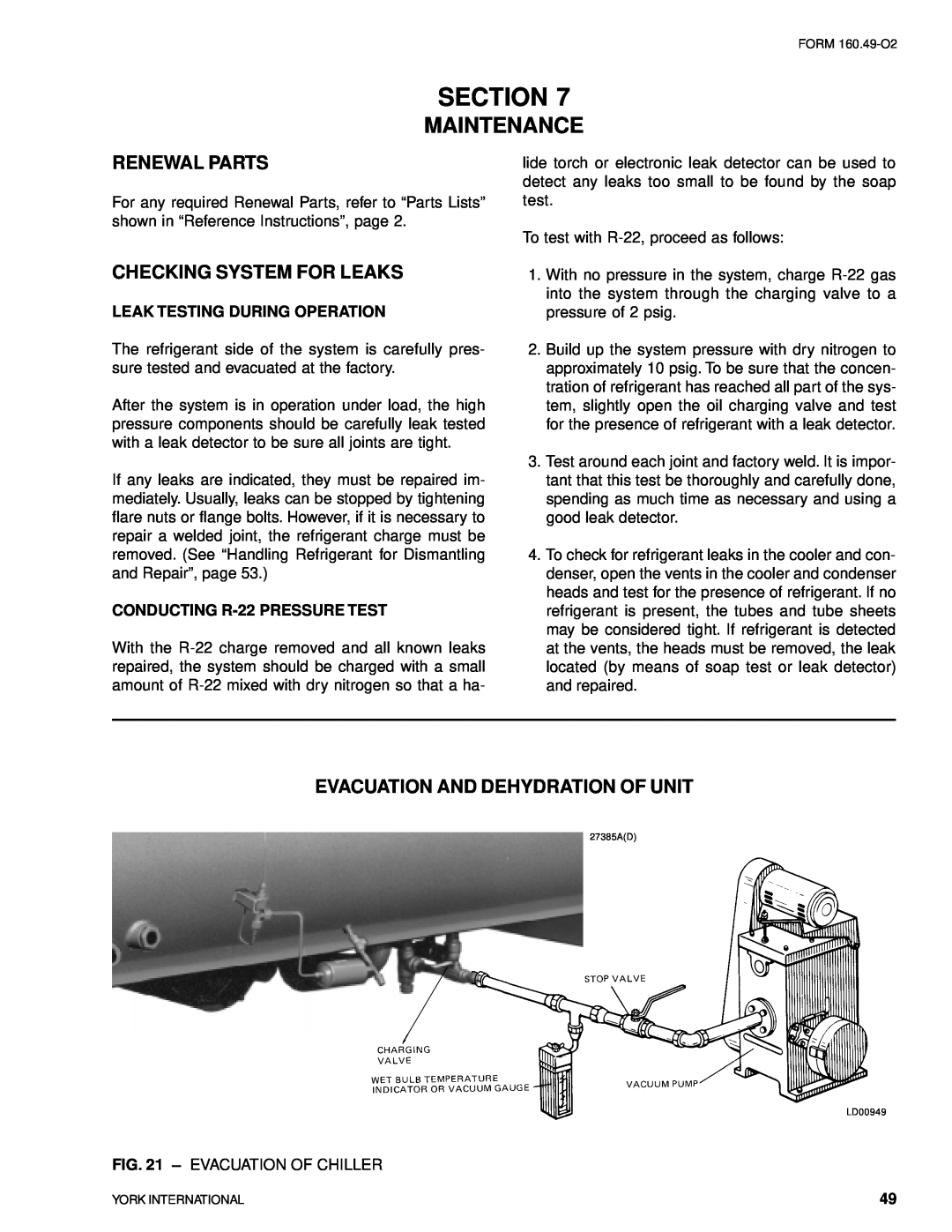

EVACUATION AND DEHYDRATION OF UNIT

27385A(D)

LD00949

FIG. 21 – EVACUATION OF CHILLER

YORK INTERNATIONAL | 49 |