SECTION 5

OPERATIONAL MAINTENANCE

OIL RETURN SYSTEM

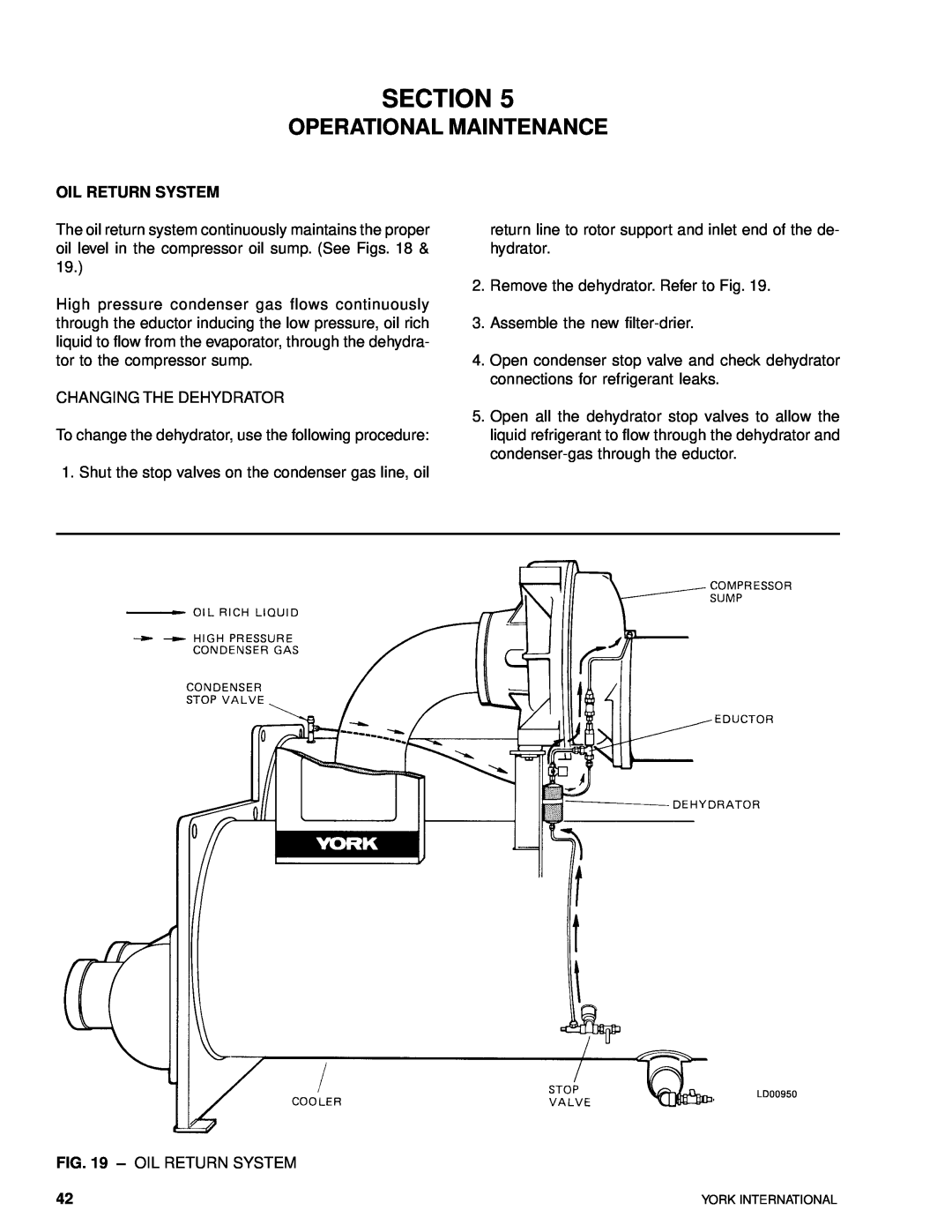

The oil return system continuously maintains the proper oil level in the compressor oil sump. (See Figs. 18 & 19.)

High pressure condenser gas flows continuously through the eductor inducing the low pressure, oil rich liquid to flow from the evaporator, through the dehydra- tor to the compressor sump.

CHANGING THE DEHYDRATOR

To change the dehydrator, use the following procedure:

1. Shut the stop valves on the condenser gas line, oil

return line to rotor support and inlet end of the de- hydrator.

2.Remove the dehydrator. Refer to Fig. 19.

3.Assemble the new

4.Open condenser stop valve and check dehydrator connections for refrigerant leaks.

5.Open all the dehydrator stop valves to allow the liquid refrigerant to flow through the dehydrator and

LD00950

FIG. 19 – OIL RETURN SYSTEM

42 | YORK INTERNATIONAL |