FORM

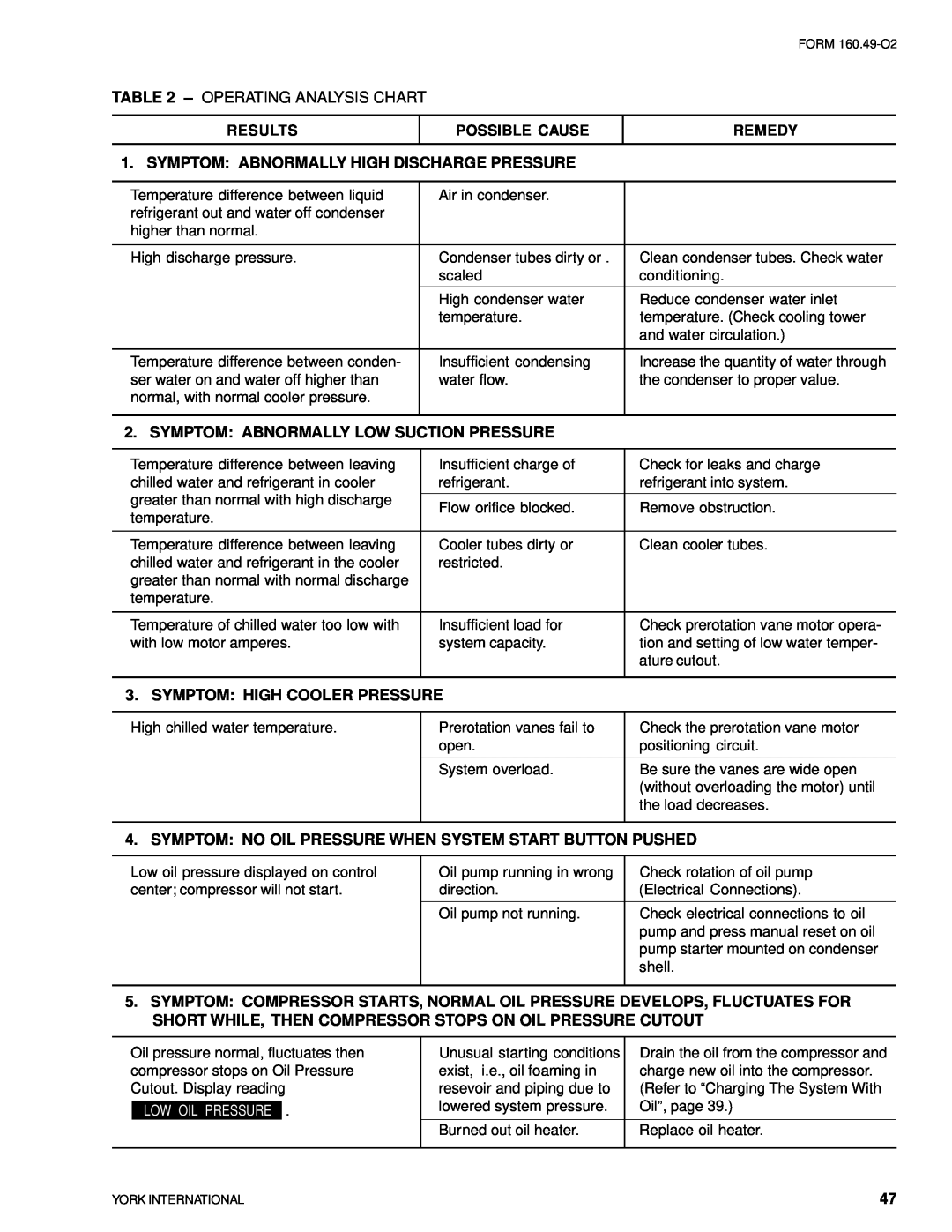

TABLE 2 – OPERATING ANALYSIS CHART

RESULTS | POSSIBLE CAUSE | REMEDY | |

|

|

| |

1. SYMPTOM: ABNORMALLY HIGH DISCHARGE PRESSURE |

| ||

|

|

| |

Temperature difference between liquid | Air in condenser. |

| |

refrigerant out and water off condenser |

|

| |

higher than normal. |

|

| |

|

|

| |

High discharge pressure. | Condenser tubes dirty or . | Clean condenser tubes. Check water | |

| scaled | conditioning. | |

|

|

| |

| High condenser water | Reduce condenser water inlet | |

| temperature. | temperature. (Check cooling tower | |

|

| and water circulation.) | |

|

|

| |

Temperature difference between conden- | Insufficient condensing | Increase the quantity of water through | |

ser water on and water off higher than | water flow. | the condenser to proper value. | |

normal, with normal cooler pressure. |

|

| |

|

|

| |

2. SYMPTOM: ABNORMALLY LOW SUCTION PRESSURE |

| ||

|

|

| |

Temperature difference between leaving | Insufficient charge of | Check for leaks and charge | |

chilled water and refrigerant in cooler | refrigerant. | refrigerant into system. | |

greater than normal with high discharge |

|

| |

Flow orifice blocked. | Remove obstruction. | ||

temperature. | |||

|

| ||

|

|

| |

Temperature difference between leaving | Cooler tubes dirty or | Clean cooler tubes. | |

chilled water and refrigerant in the cooler | restricted. |

| |

greater than normal with normal discharge |

|

| |

temperature. |

|

| |

|

|

| |

Temperature of chilled water too low with | Insufficient load for | Check prerotation vane motor opera- | |

with low motor amperes. | system capacity. | tion and setting of low water temper- | |

|

| ature cutout. | |

|

|

| |

3. SYMPTOM: HIGH COOLER PRESSURE |

| ||

|

|

| |

High chilled water temperature. | Prerotation vanes fail to | Check the prerotation vane motor | |

| open. | positioning circuit. | |

|

|

| |

| System overload. | Be sure the vanes are wide open | |

|

| (without overloading the motor) until | |

|

| the load decreases. | |

|

|

| |

4. SYMPTOM: NO OIL PRESSURE WHEN SYSTEM START BUTTON PUSHED

Low oil pressure displayed on control center; compressor will not start.

Oil pump running in wrong | Check rotation of oil pump |

direction. | (Electrical Connections). |

|

|

Oil pump not running. | Check electrical connections to oil |

| pump and press manual reset on oil |

| pump starter mounted on condenser |

| shell. |

|

|

5.SYMPTOM: COMPRESSOR STARTS, NORMAL OIL PRESSURE DEVELOPS, FLUCTUATES FOR SHORT WHILE, THEN COMPRESSOR STOPS ON OIL PRESSURE CUTOUT

Oil pressure normal, fluctuates then compressor stops on Oil Pressure Cutout. Display reading

LOW OIL PRESSURE .

Unusual starting conditions | Drain the oil from the compressor and |

exist, i.e., oil foaming in | charge new oil into the compressor. |

resevoir and piping due to | (Refer to “Charging The System With |

lowered system pressure. | Oil”, page 39.) |

|

|

Burned out oil heater. | Replace oil heater. |

|

|

YORK INTERNATIONAL | 47 |