SECTION VIII

SPRINKLER SYSTEM

A. SPRINKLER SYSTEM DESCRIPTION

The sprinkler circuit on the dryer requires a dedicated

NOTE: The sprinkler as well as the alarm will remain on until the "amber" colored sprinkler reset button

is pressed and the temperature in the tumbler (basket) falls below 700º F (371.11º C).

1.Description Of Components

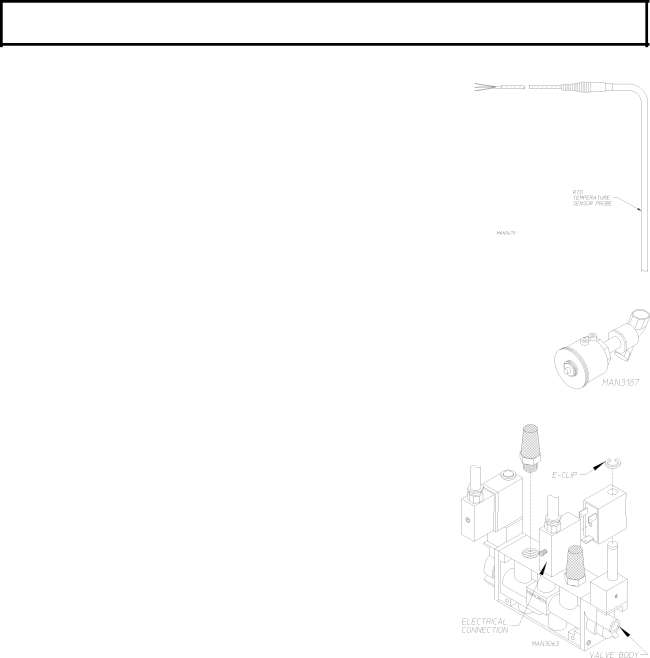

a.Resistive Temperature Device (RTD)

The RTD (Resistive Temperature Device) probe is located above the tumbler (basket). The probe is a 100 ohm (100 Ω ) platinum RTD. As

the drying temperature increases or decreases, the resistance value corresponds to the ambient temperature (i.e., 100 ohms [10 Ω ] will be equivalent to 32º F [0º C], 109 ohms [109 Ω ] will be equivalent to 37º F [24º C]).

b. Sprinkler Valve

The sprinkler valve is a

With pilot air pressure applied, the valve opens allowing water to flow

c. Sprinkler Solenoid Valve

The sprinkler solenoid valve is a

81