b.Regulator Operation

The adjustment knob simply acts upon a spring rest located on the spring and directly compresses the spring as it is adjusted. A non-rising low torque adjustment screw is used on this type of filter and regulator. The upper spring rest is located on top of the regulator spring and transmits force from the adjustment screw to the spring. Regulators use simple wire coil springs for controlling the downstream regulator pressure. The bonnet houses the adjustment spring and is used to help retain the diaphragm. The diaphragm moves up when the downstream pressure reaches its preset pressure level, which in turn closes the valve. A self-relieving regulator is designed to automatically relieve overpressure in the secondary side of the regulator.

NOTE: THIS SELF-RELIEVING FEATURE IS NOT DESIGNED TO BLEED THE DOWN- STREAM PRESSURE.

Dryer must be provided with a clean, dry, regulated 80 PSI (+/- 10 PSI) air supply (equivalent volume - 20 cf/hr).

The regulator should be set at 80 PSI (+/- 10 PSI). To set pressure, pull the adjusting knob up and either turn the knob clockwise (CW) to increase the pressure or counterclockwise (CCW) to decrease the pressure.

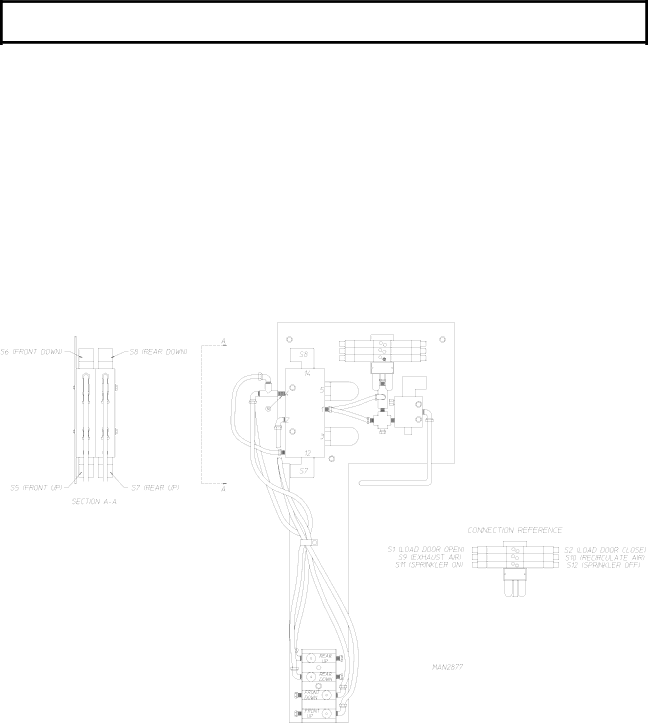

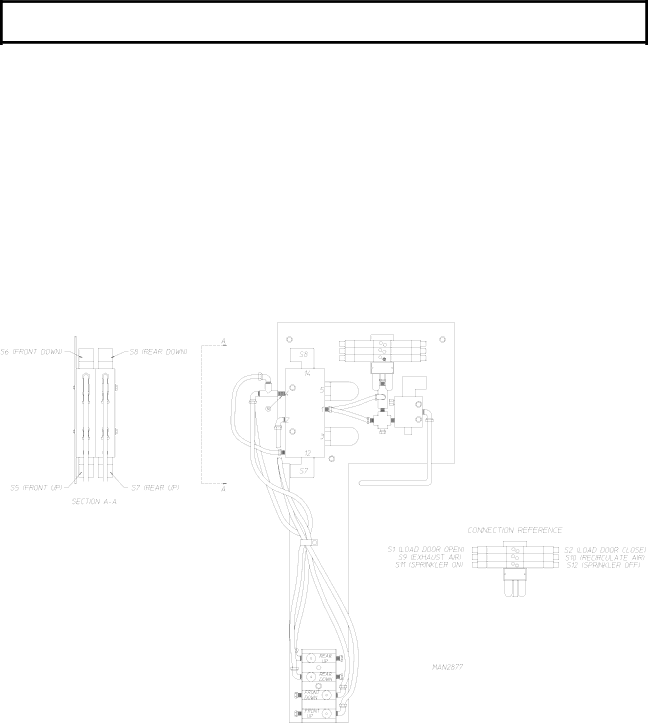

3.Pneumatic Control Panel

The pneumatic control panel of a 2-way tilt dryer has two (2) tilting solenoid valves, one to control the front set of tilting pistons and a second to control the rear set of tilting pistons. A 1-way tilt dryer has only one (1) tilting solenoid valve.

Each valve has five (5) 1/2-inch F.P.T. ports and two (2) electric solenoids, one on each side of the valve.