6.Gas Burner and Ignition System

The dryer's gas burner system operates on a on or off gas rate sequences to accurately control the tumbler’s (basket's) drying temperature. Maximum firing rate is 2.8 million btu/hr.

Upon a call from heat, the dryer computer sends a 120 volt signal to the burner controller module (BCM) which initiates and controls the ignition sequences. The BCM insures that ALL the safety switches are closed before turning on the combustion air burner fan, then checks to ensure that the burner fan air switch has closed. The pilot gas flame is then established, the flame rod, (which sits in this pilot flame), comes in contact with the flame and signals the BCM. The main motorized gas valves open in sequence, and full operational flame is achieved.

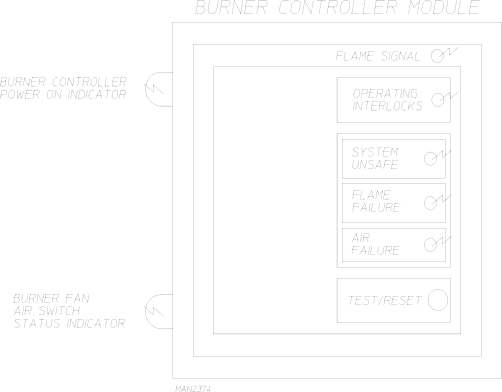

The burner controller module (BCM) has five (5) L.E.D.’s on its cover and two (2) neon’s on the mounting base for ease of troubleshooting, as well as dip switches inside for ease of programming.

The burner controller module controls ALL of the gas burner ignition components, except for the motorized gas valve. When the drying set point temperature is reached, the dryer’s computer closes the top motorized gas valve, shutting off full flame.

52