NOTE: The hose or accessory will require a quick connect plug if the air outlet is equipped with a quick connect socket.

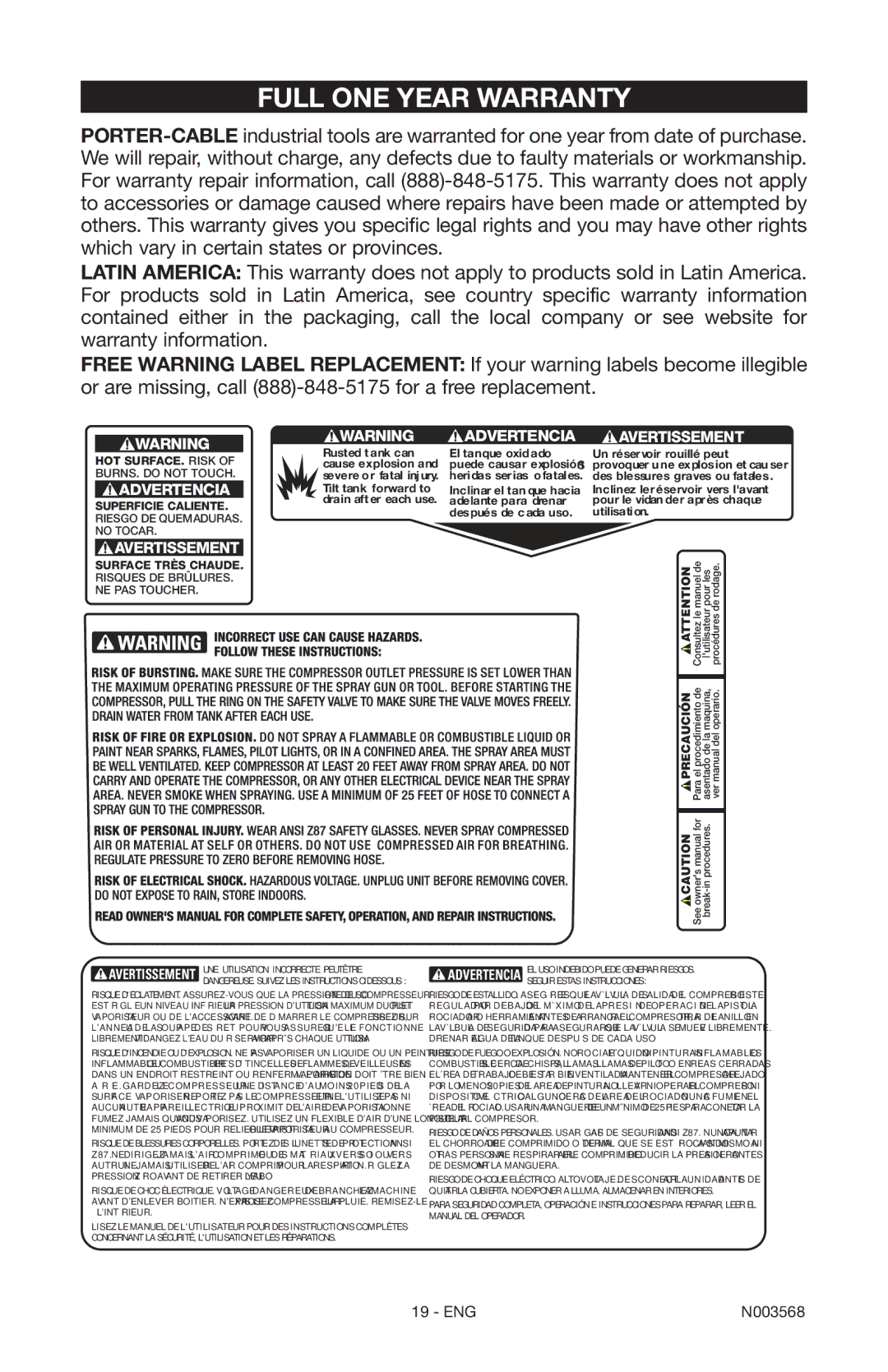

Risk of Bursting. Too much air pressure causes a hazardous ![]() risk of bursting. Check the manufacturer’s maximum pres- sure rating for air tools and accessories. The regulator outlet pressure must

risk of bursting. Check the manufacturer’s maximum pres- sure rating for air tools and accessories. The regulator outlet pressure must

never exceed the maximum pressure rating.

Risk of unsafe operation. Compressed air from the unit may ![]() contain water condensation and oil mist. Do not spray unfiltered air at an item that could be damaged by moisture. Some air tools and accessories

contain water condensation and oil mist. Do not spray unfiltered air at an item that could be damaged by moisture. Some air tools and accessories

may require filtered air. Read the instructions for the air tools and accessories.

How to Start

1.Set the On/Off switch to "On" and allow tank pressure to build. Motor will stop when tank pressure reaches

2.Turn regulator knob clockwise to increase pressure and stop when desired pressure is reached.

Risk of unsafe operation. If any unusual noise or vibration is noticed, stop the compressor immediately and have it

checked by a trained service technician.

The compressor is ready for use.

MAINTENANCE

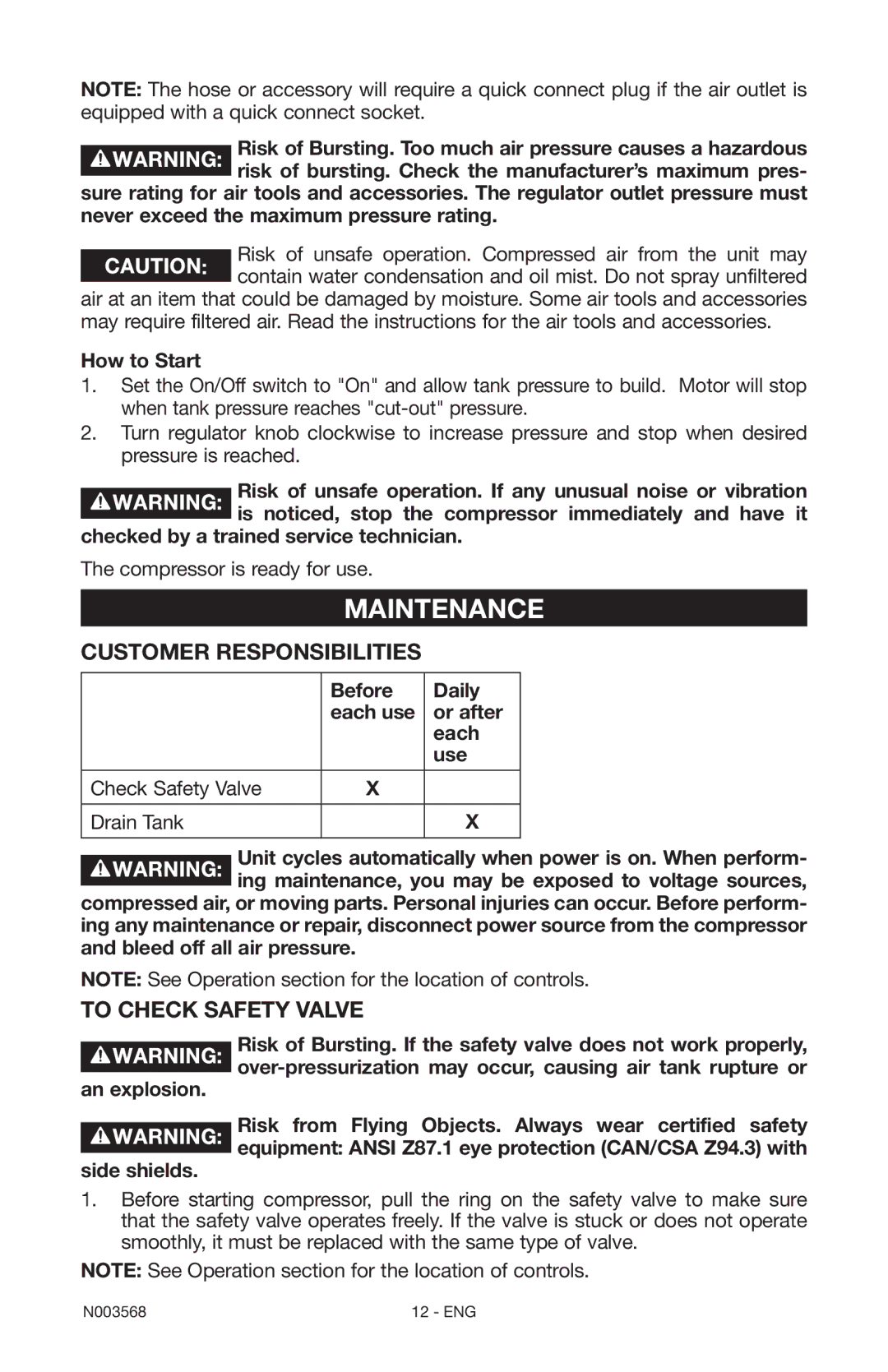

Customer Responsibilities

| Before | Daily |

| each use | or after |

|

| each |

|

| use |

|

|

|

Check Safety Valve | X |

|

|

|

|

Drain Tank |

| X |

|

|

|

Unit cycles automatically when power is on. When perform- ![]() ing maintenance, you may be exposed to voltage sources, compressed air, or moving parts. Personal injuries can occur. Before perform-

ing maintenance, you may be exposed to voltage sources, compressed air, or moving parts. Personal injuries can occur. Before perform-

ing any maintenance or repair, disconnect power source from the compressor and bleed off all air pressure.

NOTE: See Operation section for the location of controls.

To Check Safety Valve

Risk of Bursting. If the safety valve does not work properly,

an explosion.

Risk from Flying Objects. Always wear certified safety equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with

side shields.

1.Before starting compressor, pull the ring on the safety valve to make sure that the safety valve operates freely. If the valve is stuck or does not operate smoothly, it must be replaced with the same type of valve.

NOTE: See Operation section for the location of controls.

N003568 | 12 - ENG |