Applications

•Ambient air analysis

•Odor nuisance monitoring

•Regulatory compliance

•Control room corrosion monitoring

•Quality control

•Scrubber efficiency testing

•Accuracy check for other hydrogen sulfide monitors and control systems

•Hydrogen sulfide source detection

•Leak detection

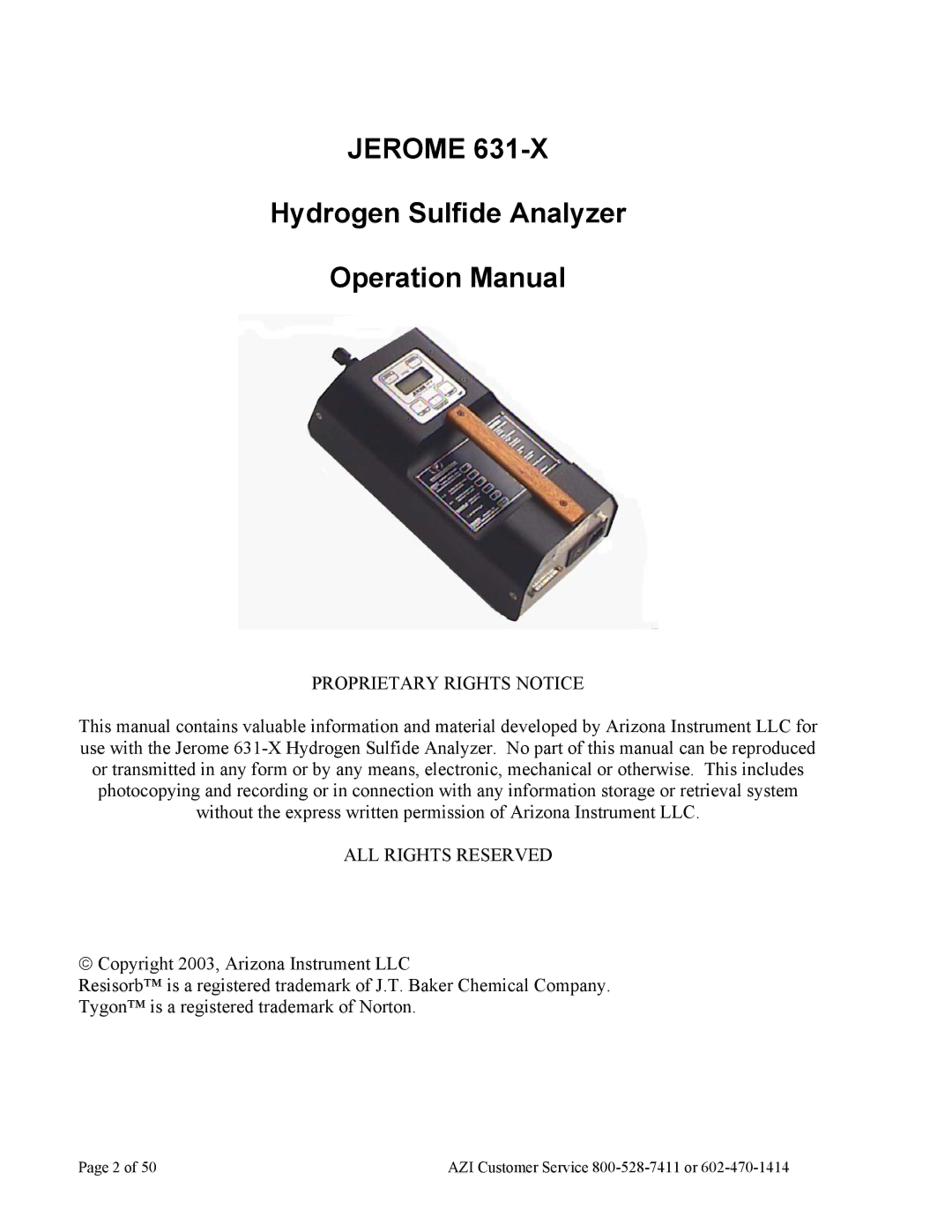

•The Jerome

3. PRINCIPLE OF OPERATION

3. PRINCIPLE OF OPERATION

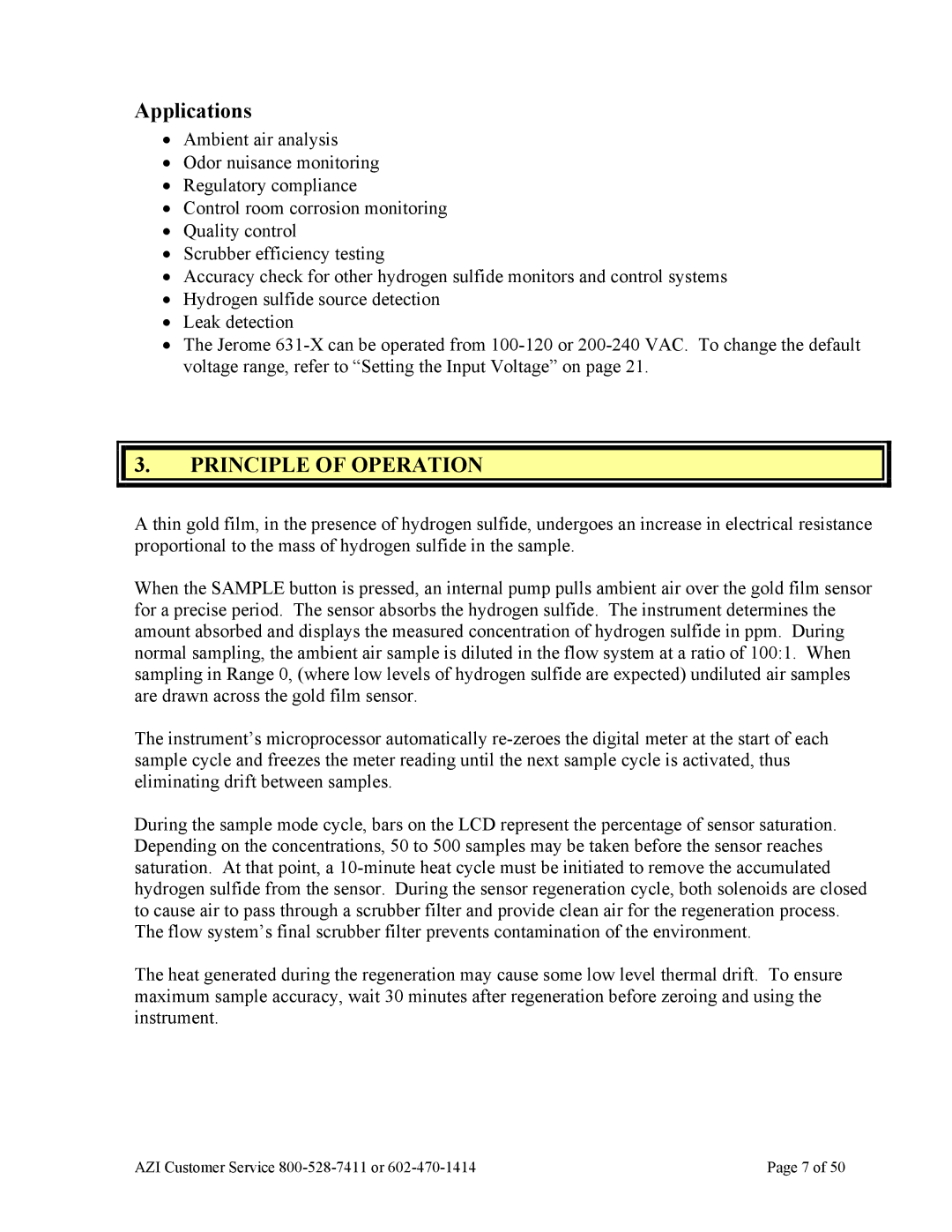

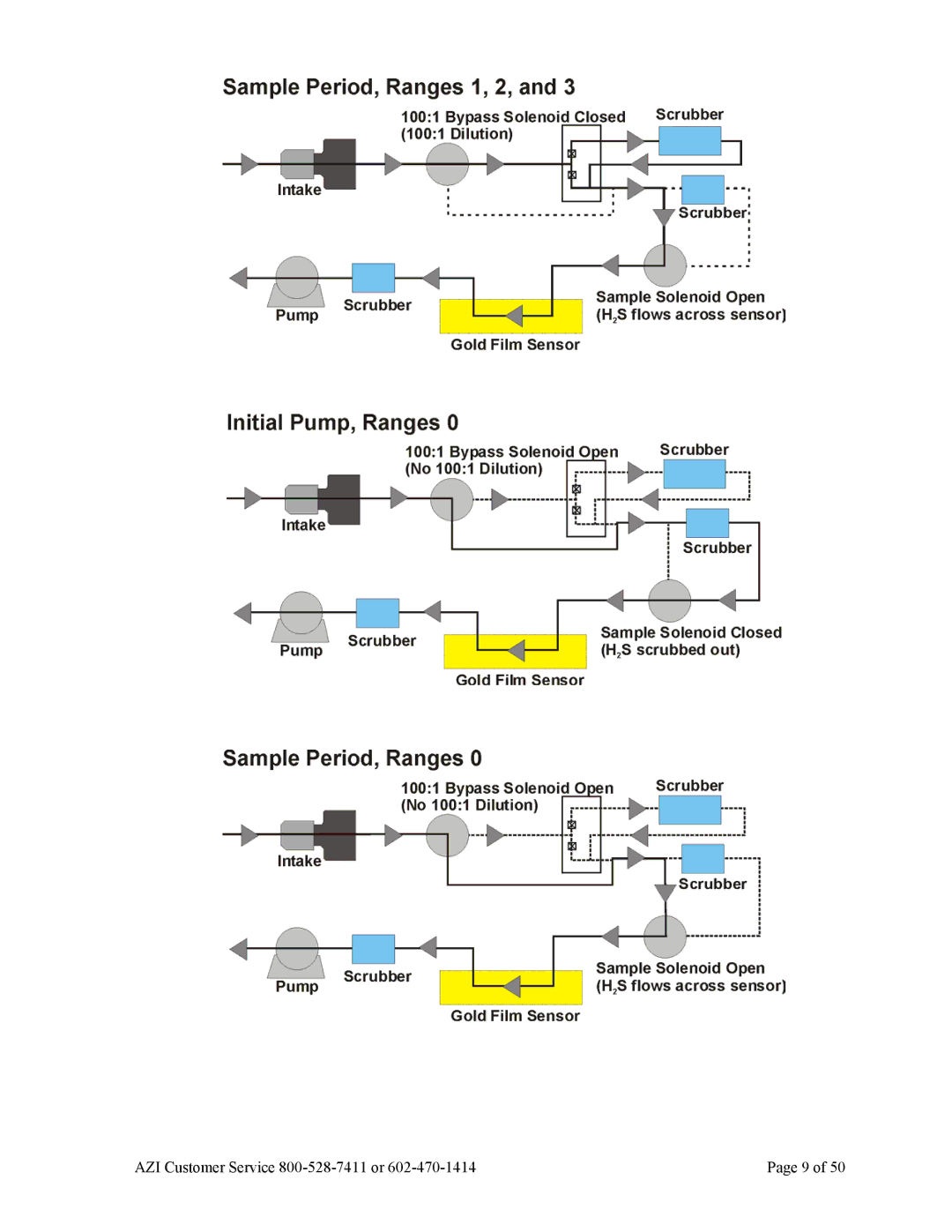

A thin gold film, in the presence of hydrogen sulfide, undergoes an increase in electrical resistance proportional to the mass of hydrogen sulfide in the sample.

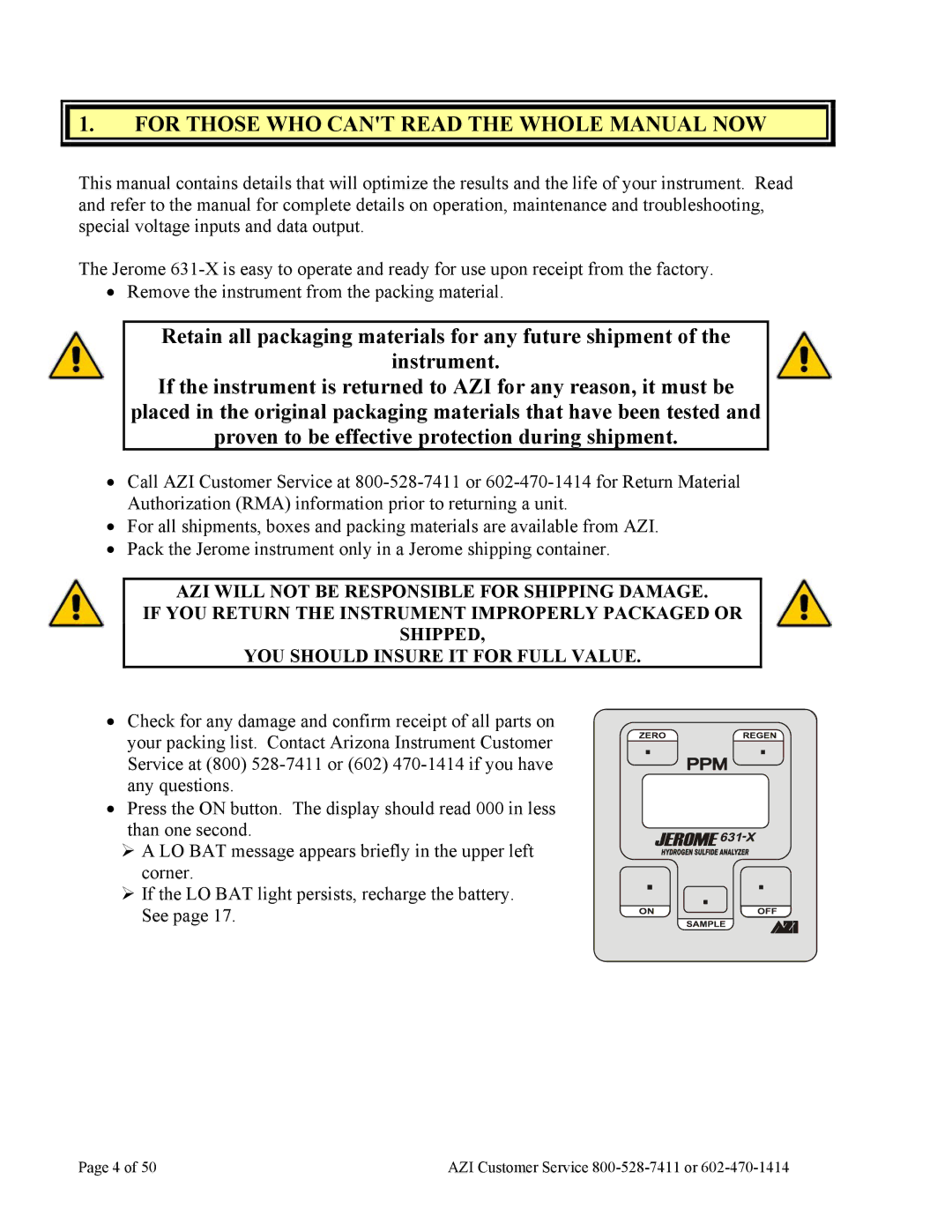

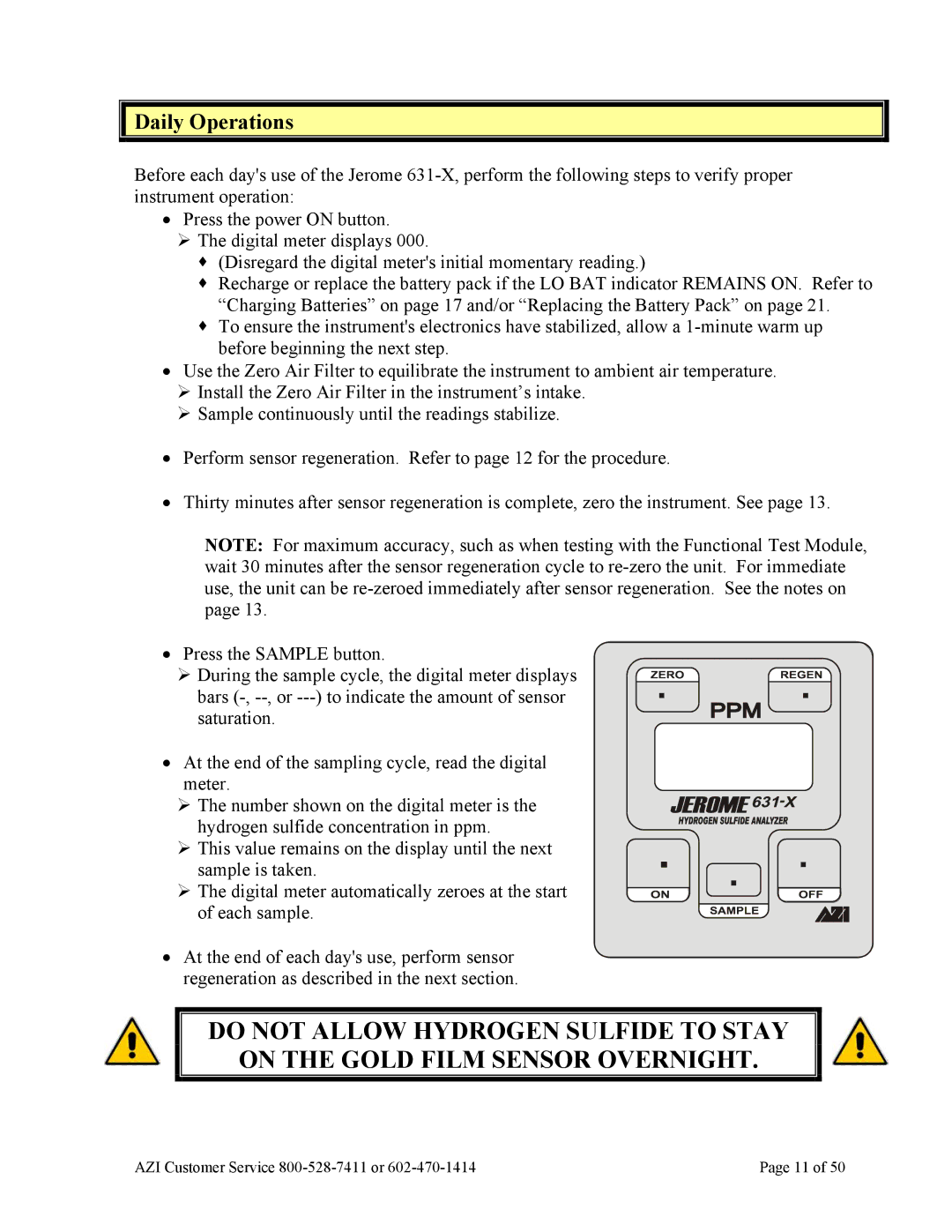

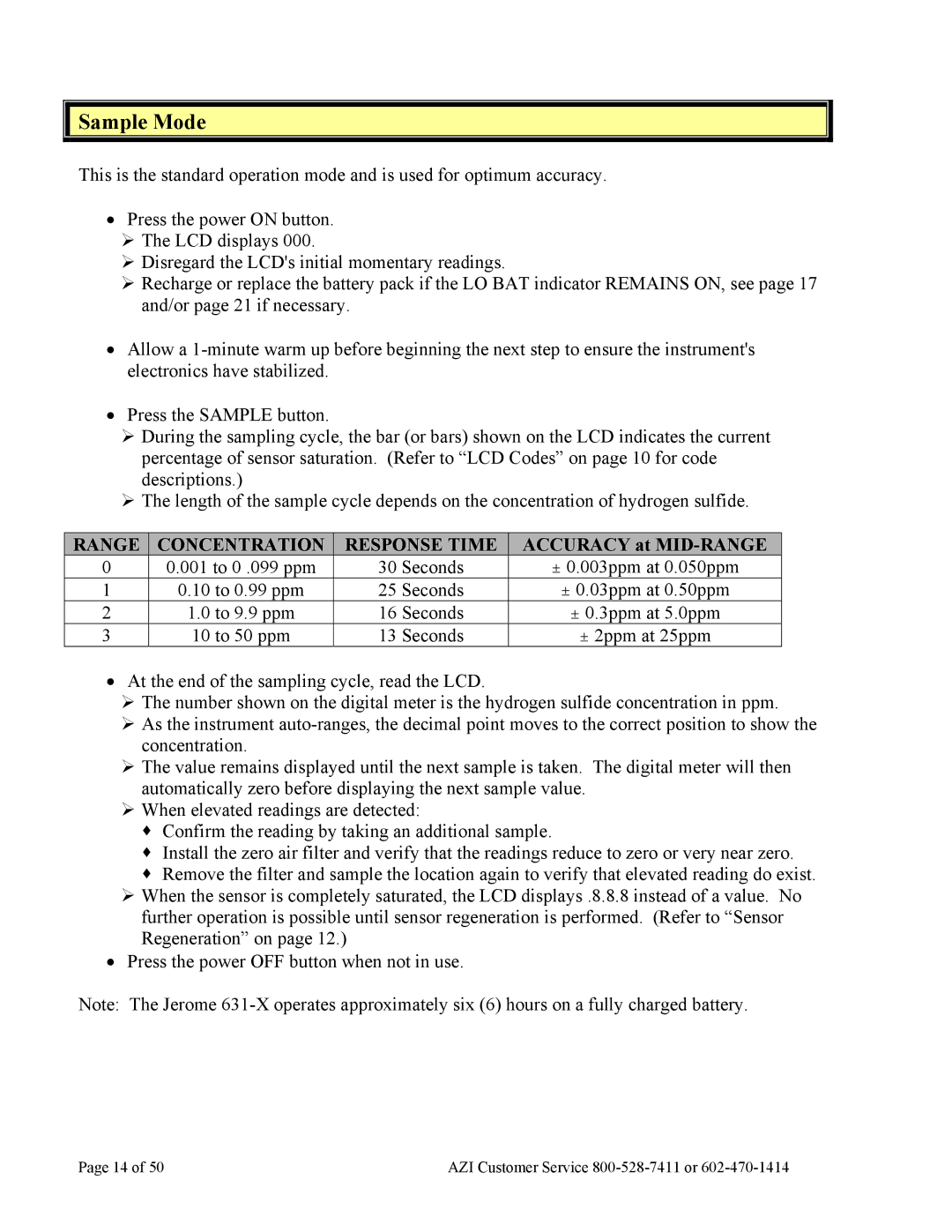

When the SAMPLE button is pressed, an internal pump pulls ambient air over the gold film sensor for a precise period. The sensor absorbs the hydrogen sulfide. The instrument determines the amount absorbed and displays the measured concentration of hydrogen sulfide in ppm. During normal sampling, the ambient air sample is diluted in the flow system at a ratio of 100:1. When sampling in Range 0, (where low levels of hydrogen sulfide are expected) undiluted air samples are drawn across the gold film sensor.

The instrument’s microprocessor automatically

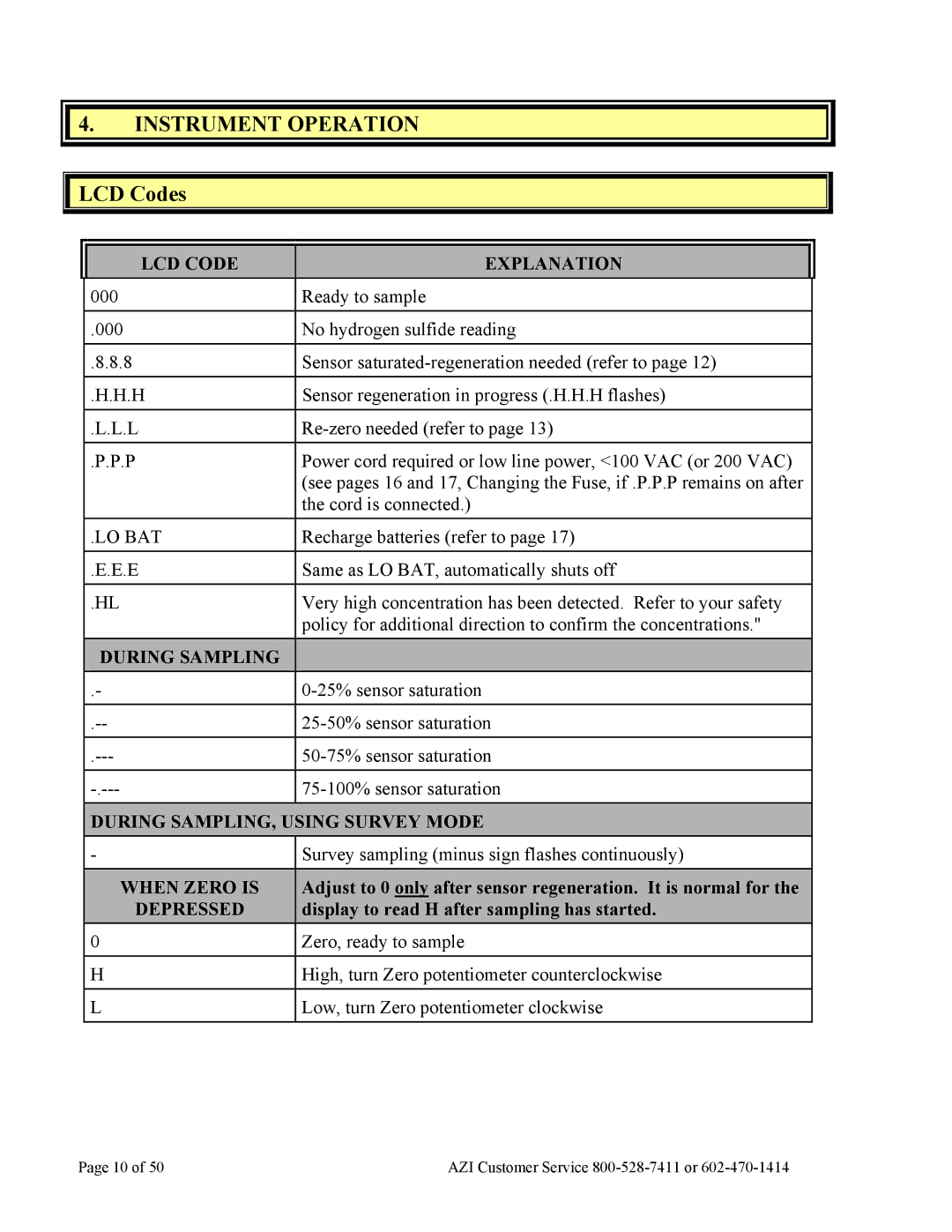

During the sample mode cycle, bars on the LCD represent the percentage of sensor saturation. Depending on the concentrations, 50 to 500 samples may be taken before the sensor reaches saturation. At that point, a

The heat generated during the regeneration may cause some low level thermal drift. To ensure maximum sample accuracy, wait 30 minutes after regeneration before zeroing and using the instrument.

AZI Customer Service | Page 7 of 50 |