Data Communications

Flow Control

The CodeWriter 4500 Series printers provide two methods to control the flow of data between the host system and the printer. Hardware or Xon/Xoff flow control is selected from the Operator Panel.

Hardware Flow Control

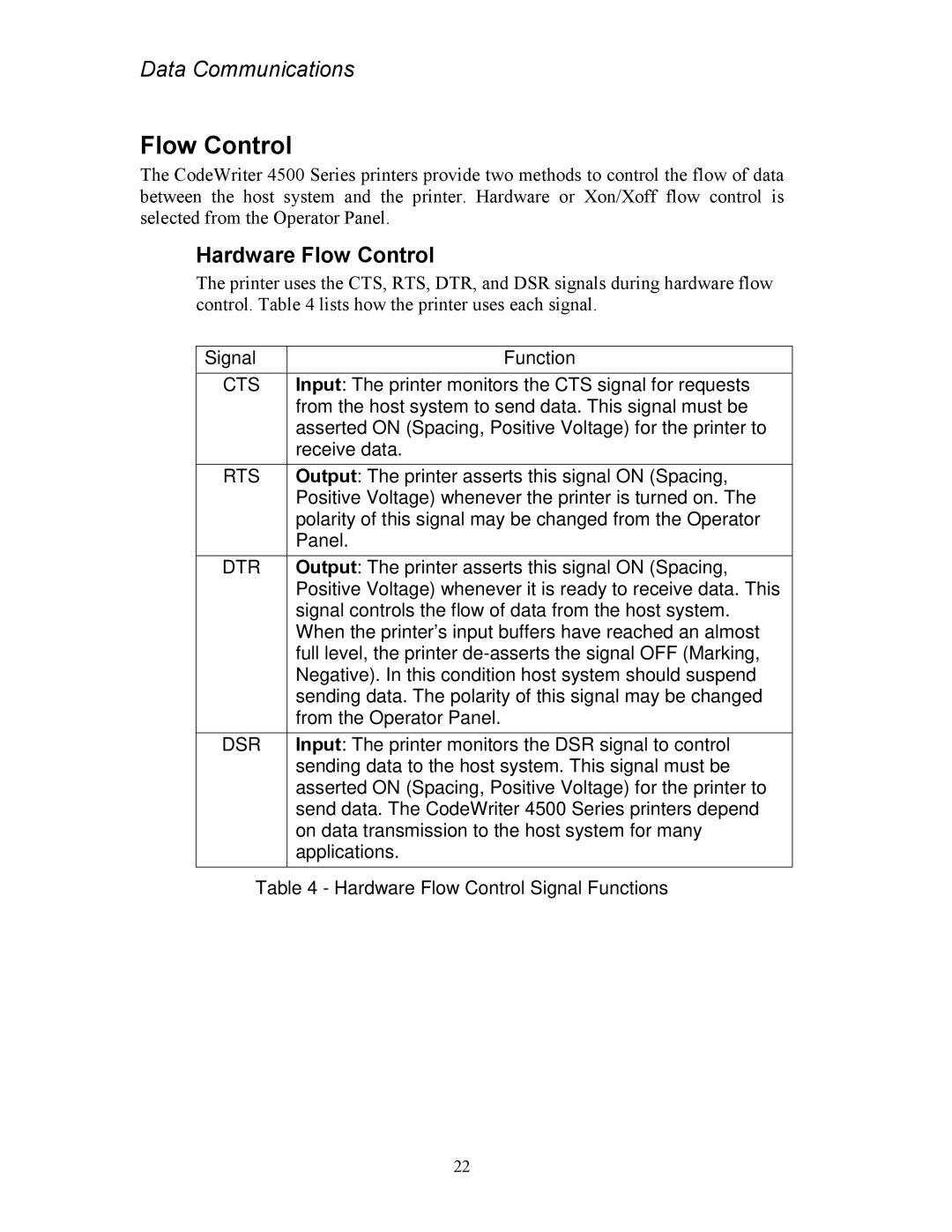

The printer uses the CTS, RTS, DTR, and DSR signals during hardware flow control. Table 4 lists how the printer uses each signal.

Signal | Function |

CTS | Input: The printer monitors the CTS signal for requests |

| from the host system to send data. This signal must be |

| asserted ON (Spacing, Positive Voltage) for the printer to |

| receive data. |

RTS | Output: The printer asserts this signal ON (Spacing, |

| Positive Voltage) whenever the printer is turned on. The |

| polarity of this signal may be changed from the Operator |

| Panel. |

DTR | Output: The printer asserts this signal ON (Spacing, |

| Positive Voltage) whenever it is ready to receive data. This |

| signal controls the flow of data from the host system. |

| When the printer’s input buffers have reached an almost |

| full level, the printer |

| Negative). In this condition host system should suspend |

| sending data. The polarity of this signal may be changed |

| from the Operator Panel. |

DSR | Input: The printer monitors the DSR signal to control |

| sending data to the host system. This signal must be |

| asserted ON (Spacing, Positive Voltage) for the printer to |

| send data. The CodeWriter 4500 Series printers depend |

| on data transmission to the host system for many |

| applications. |

Table 4 - Hardware Flow Control Signal Functions

22