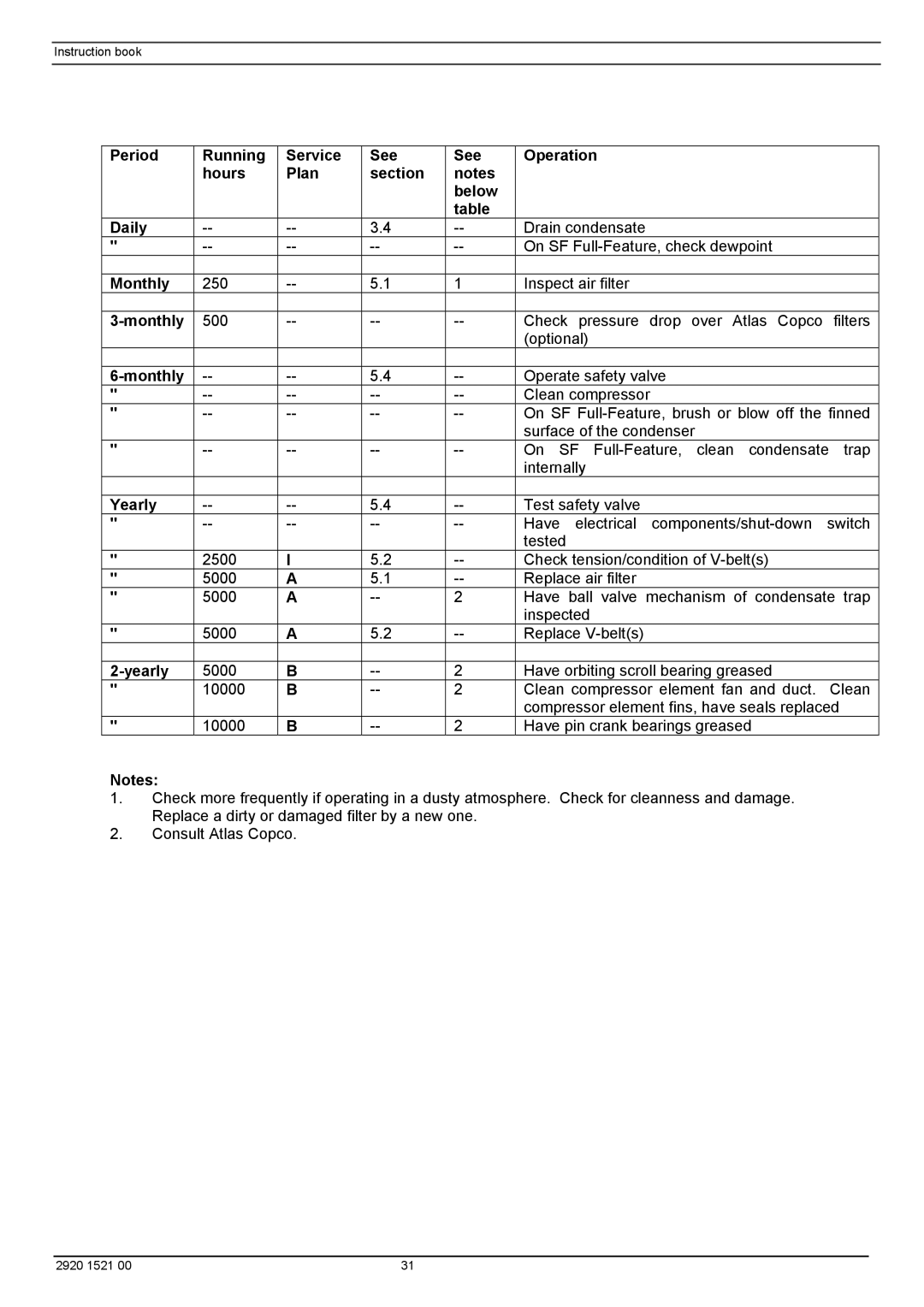

Instruction book

Period | Running | Service | See | See | Operation |

| hours | Plan | section | notes |

|

|

|

|

| below |

|

|

|

|

| table |

|

Daily | 3.4 | Drain condensate | |||

" | On SF | ||||

|

|

|

|

|

|

Monthly | 250 | 5.1 | 1 | Inspect air filter | |

|

|

|

|

|

|

500 | Check pressure drop over Atlas Copco filters | ||||

|

|

|

|

| (optional) |

|

|

|

|

|

|

5.4 | Operate safety valve | ||||

" | Clean compressor | ||||

" | On SF | ||||

|

|

|

|

| surface of the condenser |

" | On SF | ||||

|

|

|

|

| internally |

|

|

|

|

|

|

Yearly | 5.4 | Test safety valve | |||

" | Have electrical | ||||

|

|

|

|

| tested |

" | 2500 | I | 5.2 | Check tension/condition of | |

" | 5000 | A | 5.1 | Replace air filter | |

" | 5000 | A | 2 | Have ball valve mechanism of condensate trap | |

|

|

|

|

| inspected |

" | 5000 | A | 5.2 | Replace | |

|

|

|

|

|

|

5000 | B | 2 | Have orbiting scroll bearing greased | ||

" | 10000 | B | 2 | Clean compressor element fan and duct. Clean | |

|

|

|

|

| compressor element fins, have seals replaced |

" | 10000 | B | 2 | Have pin crank bearings greased |

Notes:

1.Check more frequently if operating in a dusty atmosphere. Check for cleanness and damage. Replace a dirty or damaged filter by a new one.

2.Consult Atlas Copco.

2920 1521 00 | 31 |