Examples:

A 5hp, 230VAC control operating at 208VAC has a reduced power rating of 4.5hp.

5HP | 208VAC | + | 4.5hp |

230VAC |

Likewise, a 3hp, 460VAC control operating at 380VAC has a reduced power rating of 2.47hp.

3HP | 380VAC | + | 2.47hp |

460VAC |

Electrical Installation All interconnection wires between the control, AC power source, motor, host control and any operator interface stations should be in metal conduits or shielded cable must be used. Use listed closed loop connectors that are of appropriate size for wire gauge being used. Connectors are to be installed using crimp tool specified by the manufacturer of the connector. Only class 1 wiring should be used.

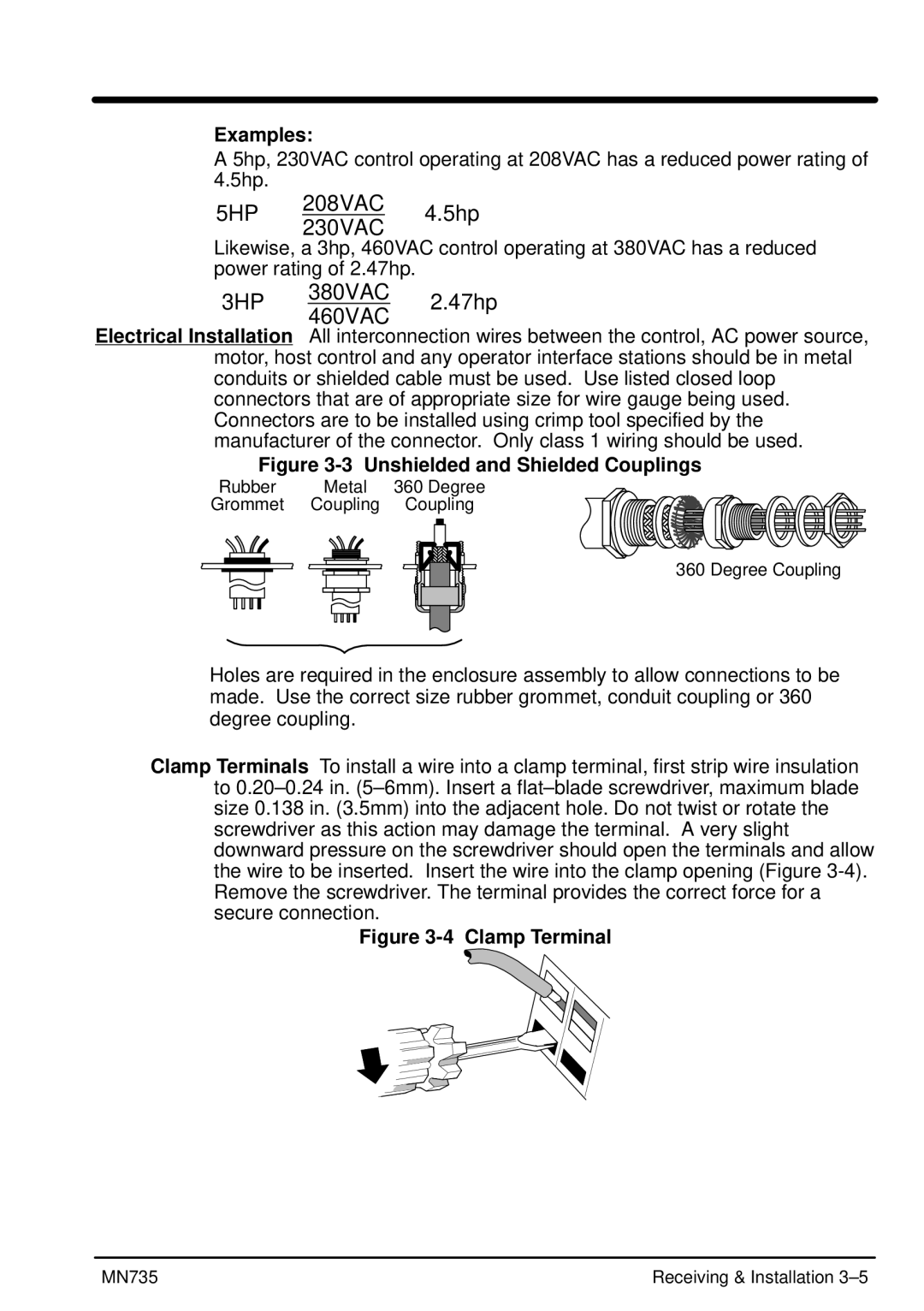

Figure 3-3 Unshielded and Shielded Couplings

Rubber | Metal | 360 Degree |

Grommet | Coupling | Coupling |

360 Degree Coupling

Holes are required in the enclosure assembly to allow connections to be made. Use the correct size rubber grommet, conduit coupling or 360 degree coupling.

Clamp Terminals To install a wire into a clamp terminal, first strip wire insulation to

Figure 3-4 Clamp Terminal

MN735 | Receiving & Installation |