The gains should be

To set up the P gain, set the I gain to zero. Apply a step change in setpoint that is typical for the System, and observe the response. Increase the gain and repeat the test until the system becomes oscillatory. At this point, reduce the P gain until the oscillations disappear. This is the maximum value of P gain achievable.

If a steady state error is present, i.e. the feedback never reaches the setpoint value, the I gain needs to be increased. As before, increase the I gain and apply the step change. Monitor the output. If the output becomes oscillatory, reduce the P gain slightly. This should reduce the steady state error. Increasing the I gain further may reduce the time to achieve zero steady state error.

These values of P and I can now be adjusted to provide the exact response required for this step change.

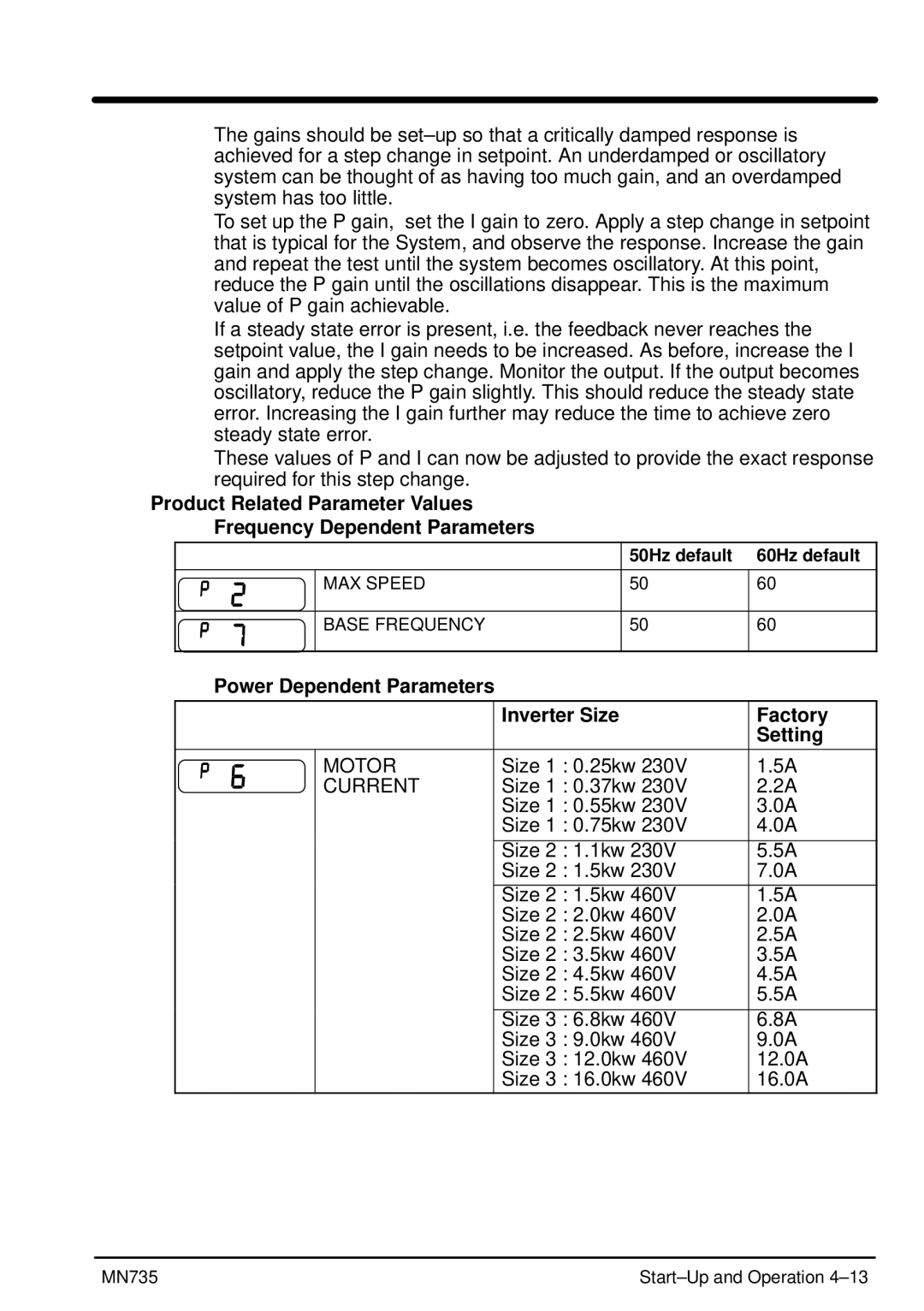

Product Related Parameter Values

Frequency Dependent Parameters

| 50Hz default | 60Hz default |

MAX SPEED | 50 | 60 |

BASE FREQUENCY

50

60

Power Dependent Parameters

|

| Inverter Size | Factory | |

|

|

|

| Setting |

|

|

|

| |

| MOTOR | Size 1 : 0.25kw 230V | 1.5A | |

| CURRENT | Size 1 : 0.37kw 230V | 2.2A | |

|

| Size 1 : 0.55kw 230V | 3.0A | |

|

| Size 1 : 0.75kw 230V | 4.0A | |

|

|

|

| |

|

| Size 2 : 1.1kw 230V | 5.5A | |

|

| Size 2 : 1.5kw 230V | 7.0A | |

|

| Size 2 : 1.5kw 460V | 1.5A | |

|

| Size 2 : 2.0kw 460V | 2.0A | |

|

| Size 2 : 2.5kw 460V | 2.5A | |

|

| Size 2 : 3.5kw 460V | 3.5A | |

|

| Size 2 : 4.5kw 460V | 4.5A | |

|

| Size 2 : 5.5kw 460V | 5.5A | |

|

|

|

|

|

|

| Size 3 | : 6.8kw 460V | 6.8A |

|

| Size 3 | : 9.0kw 460V | 9.0A |

|

| Size 3 | : 12.0kw 460V | 12.0A |

|

| Size 3 | : 16.0kw 460V | 16.0A |

MN735 |