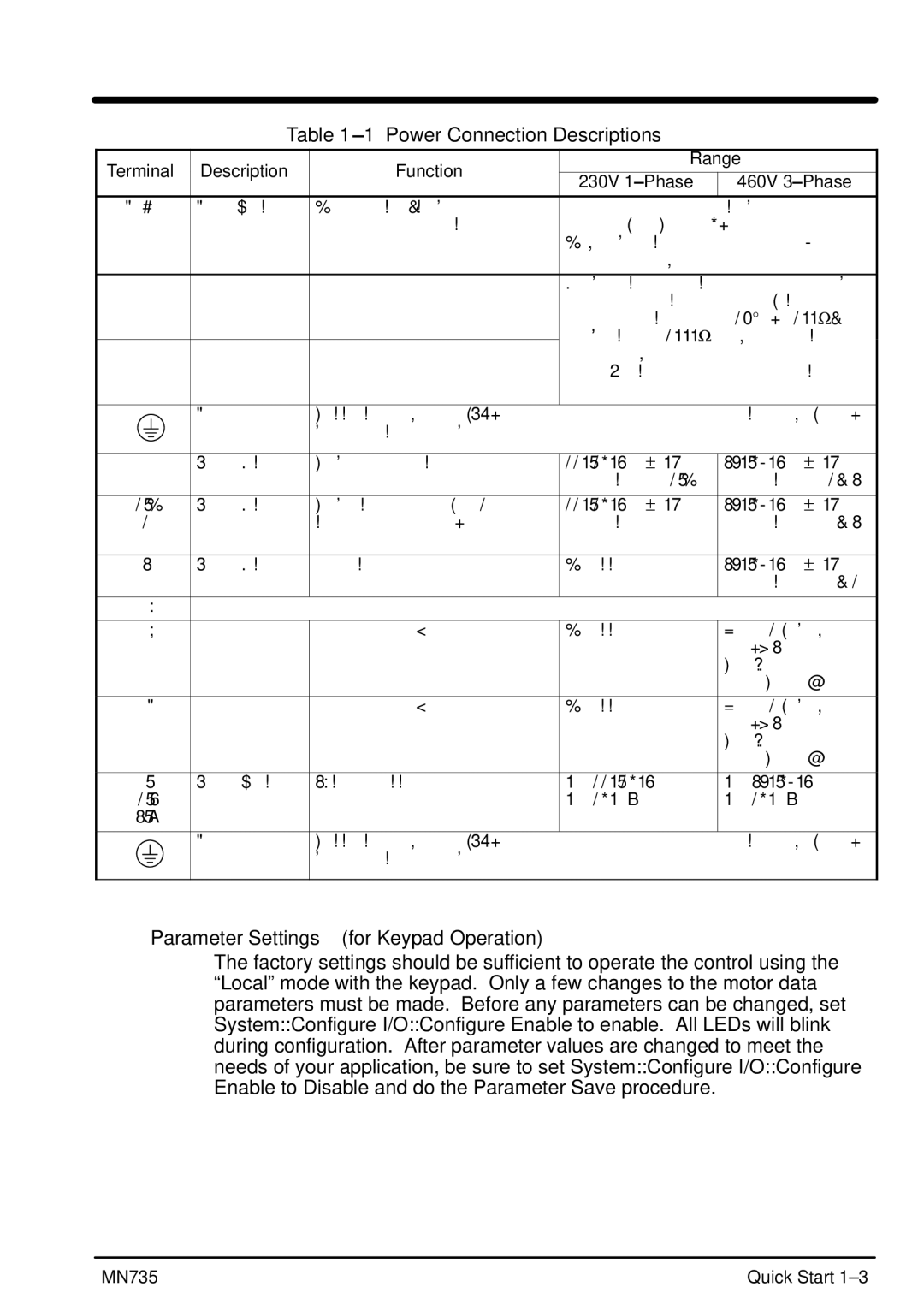

Table 1–1 Power Connection Descriptions

Terminal | Description | Function | Range | ||

230V | 460V | ||||

|

|

| |||

RLY1 | Relay Output | Normally open, programmable | Contact closes when the programmed | ||

|

| contact for a relay output. | condition (see Section 4) is true. | ||

|

|

| No voltage is present on this contact. 6 | ||

|

|

| conditions are available. | ||

|

|

|

|

| |

TH1A | Thermistor | Connection to motor thermistor | It is good practice to protect motors by using | ||

|

|

| thermistors. A typical resistance (up to a | ||

|

|

| reference temperature of 125_C) is 200Ω , | ||

|

|

| rising rapidly to 2000Ω | above this temperature. | |

TH1B | Thermistor | Connection to motor thermistor | |||

Connect devices in series between TH1A and | |||||

|

|

| |||

|

|

| TH1B. Jumper TH1A and TH1B if temperature | ||

|

|

| sensors are not used. |

| |

|

|

|

|

| |

| Reference | Supply protective earth (PE). This terminal must be connected to a protective (earth) | |||

| Terminal | ground for permanent ground. |

|

| |

|

|

|

|

| |

L1 | Power Input | Single and three phase line | 220/240VAC± 10% | 380/460VAC± 10% | |

|

| connection | with respect to L2/N. | with respect to L2, L3. | |

|

|

|

|

| |

L2/N | Power Input | Single phase neutral (or L2 three | 220/240VAC± 10% | 380/460VAC± 10% | |

L2 |

| phase line connection) | with respect to L1. | with respect to L1, L3. | |

|

|

|

|

| |

L3 | Power Input | Three phase line connection | Not applicable | 380/460VAC± 10% | |

|

|

|

| with respect to L1, L2. | |

|

|

|

|

| |

DC- |

| No user connection |

| ||

|

|

|

|

| |

DC+ | Dynamic Brake | Connection to external brake | Not applicable | Frame 2 (high volt | |

|

| resistor |

| only) & 3. | |

|

|

|

| See •Internal Dynamic | |

|

|

|

| Brake Switch" table | |

|

|

|

|

| |

DBR | Dynamic Brake | Connection to external brake | Not applicable | Frame 2 (high volt | |

|

| resistor |

| only) & 3. | |

|

|

|

| See •Internal Dynamic | |

|

|

|

| Brake Switch" table | |

|

|

|

|

| |

M1/U | Power Outputs | 0 to 220/240VAC | 0 to 380/460VAC | ||

M2/V |

| motor | 0 to 240Hz | 0 to 240Hz | |

M3/W |

|

|

|

| |

|

|

|

|

| |

| Reference | Supply protective earth (PE). This terminal must be connected to a protective (earth) | |||

| Terminal | ground for permanent ground. |

|

| |

|

|

|

|

| |

Parameter Settings (for Keypad Operation)

The factory settings should be sufficient to operate the control using the “Local” mode with the keypad. Only a few changes to the motor data parameters must be made. Before any parameters can be changed, set System::Configure I/O::Configure Enable to enable. All LEDs will blink during configuration. After parameter values are changed to meet the needs of your application, be sure to set System::Configure I/O::Configure Enable to Disable and do the Parameter Save procedure.

MN735 | Quick Start |