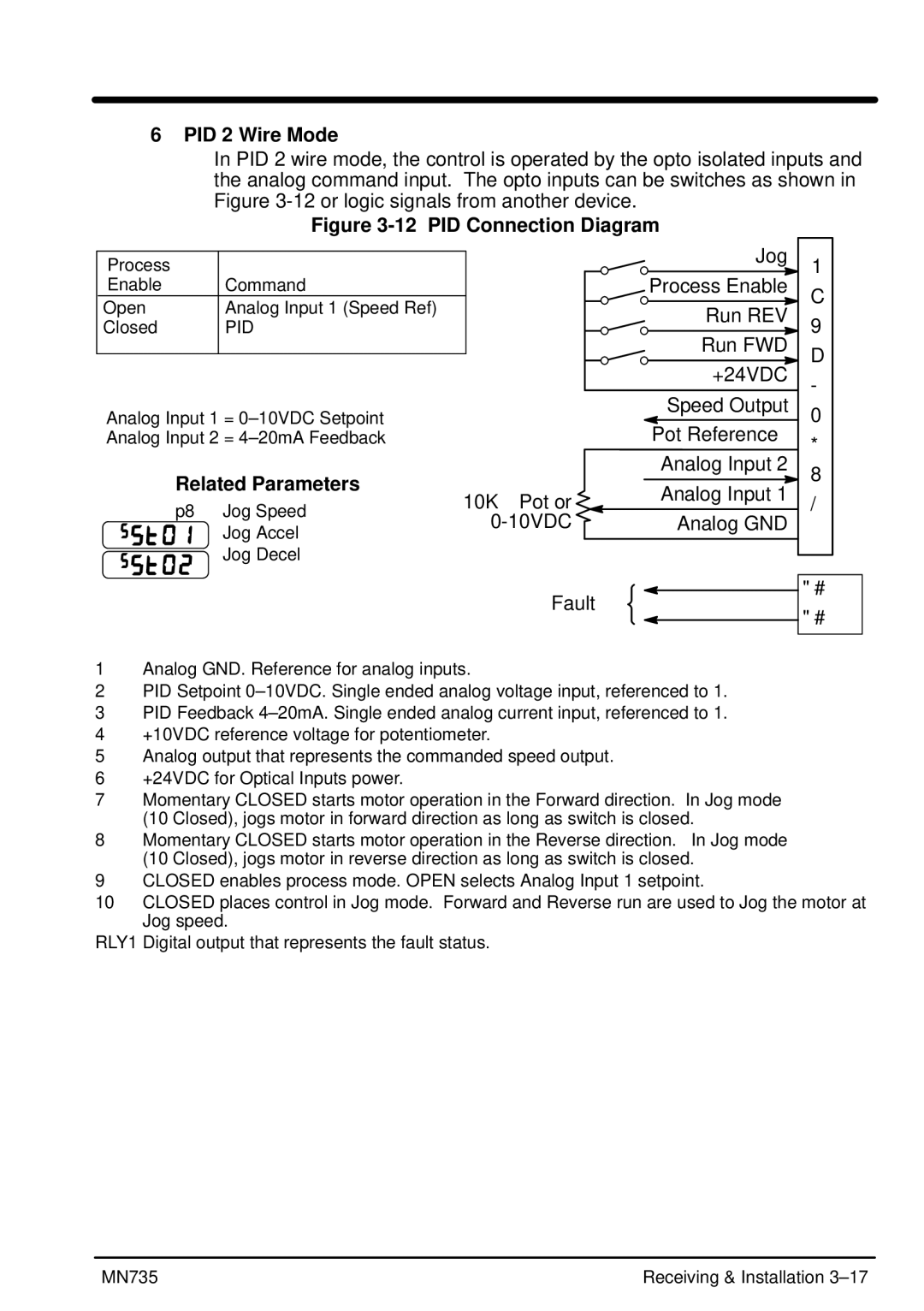

6 – PID 2 Wire Mode

In PID 2 wire mode, the control is operated by the opto isolated inputs and the analog command input. The opto inputs can be switches as shown in Figure

Figure 3-12 PID Connection Diagram

Process |

|

Enable | Command |

Open | Analog Input 1 (Speed Ref) |

Closed | PID |

|

|

Analog Input 1 =

Related Parameters

p8 Jog Speed

Jog Accel

Jog Decel

| Jog |

| Process Enable |

| Run REV |

| Run FWD |

| +24VDC |

| Speed Output |

| Pot Reference |

| Analog Input 2 |

10KW Pot or | Analog Input 1 |

| |

Analog GND |

10

9

8

7

6

5

4

3

2

1

RLY1A

Fault

RLY1B

1Analog GND. Reference for analog inputs.

2PID Setpoint

3PID Feedback

4+10VDC reference voltage for potentiometer.

5Analog output that represents the commanded speed output.

6+24VDC for Optical Inputs power.

7Momentary CLOSED starts motor operation in the Forward direction. In Jog mode (10 Closed), jogs motor in forward direction as long as switch is closed.

8Momentary CLOSED starts motor operation in the Reverse direction. In Jog mode (10 Closed), jogs motor in reverse direction as long as switch is closed.

9CLOSED enables process mode. OPEN selects Analog Input 1 setpoint.

10CLOSED places control in Jog mode. Forward and Reverse run are used to Jog the motor at Jog speed.

RLY1 Digital output that represents the fault status.

MN735 | Receiving & Installation |