5. CORRECT OPERATION

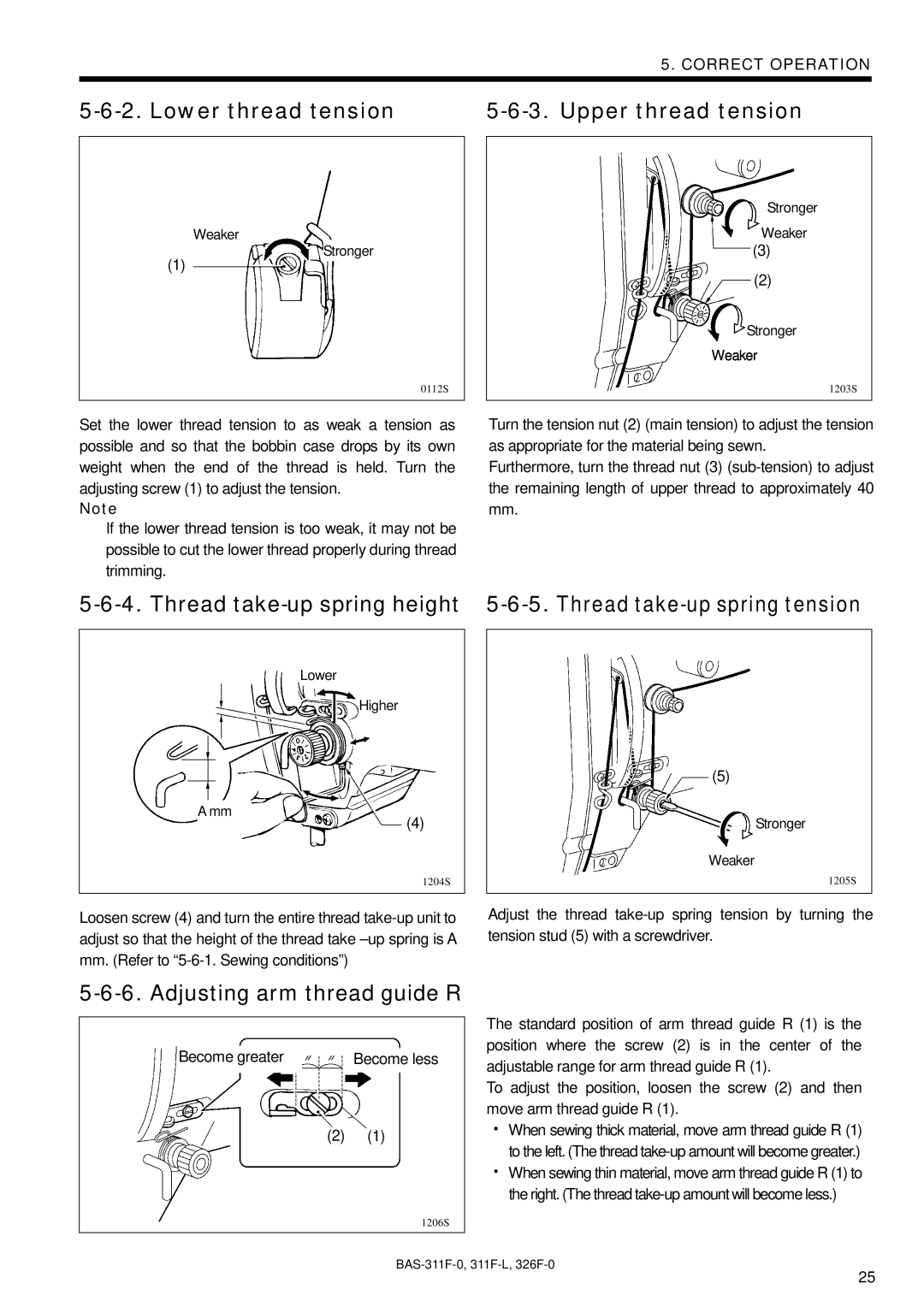

5-6-2. Lower thread tension

Weaker

Stronger

(1)

0112S

Set the lower thread tension to as weak a tension as possible and so that the bobbin case drops by its own weight when the end of the thread is held. Turn the adjusting screw (1) to adjust the tension.

Note

If the lower thread tension is too weak, it may not be possible to cut the lower thread properly during thread trimming.

5-6-4. Thread take-up spring height

Lower

Higher

A mm

(4)

1204S

Loosen screw (4) and turn the entire thread

Become greater |

| Become less |

|

|

|

(2) (1)

1206S

5-6-3. Upper thread tension

Stronger

Weaker

(3)

(2)

Stronger

Weaker

1203S

Turn the tension nut (2) (main tension) to adjust the tension as appropriate for the material being sewn.

Furthermore, turn the thread nut (3)

5-6-5. Thread take-up spring tension

(5)

Stronger

Weaker

1205S

Adjust the thread

The standard position of arm thread guide R (1) is the position where the screw (2) is in the center of the adjustable range for arm thread guide R (1).

To adjust the position, loosen the screw (2) and then move arm thread guide R (1).

![]() When sewing thick material, move arm thread guide R (1) to the left. (The thread

When sewing thick material, move arm thread guide R (1) to the left. (The thread ![]() When sewing thin material, move arm thread guide R (1) to the right. (The thread

When sewing thin material, move arm thread guide R (1) to the right. (The thread

25