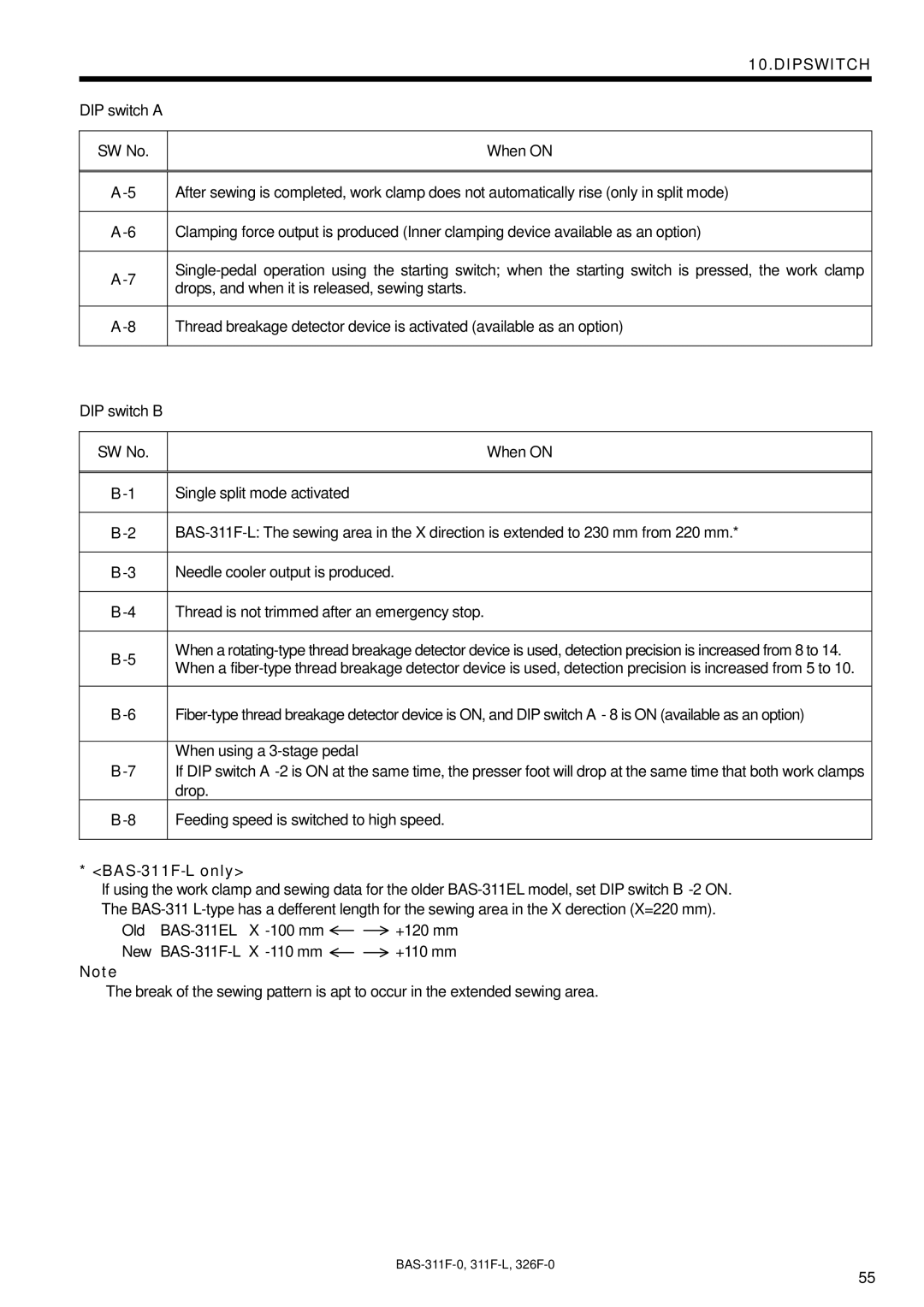

10.DIPSWITCH

DIP switch A

SW No.

When ON

After sewing is completed, work clamp does not automatically rise (only in split mode) | |

|

|

Clamping force output is produced (Inner clamping device available as an option) |

A

drops, and when it is released, sewing starts.

Thread breakage detector device is activated (available as an option) |

DIP switch B

SW No.

When ON

Single split mode activated | ||

|

| |

|

| |

Needle cooler output is produced. | ||

|

| |

Thread is not trimmed after an emergency stop. | ||

|

| |

When a | ||

When a | ||

| ||

|

| |

|

| |

When using a | ||

If DIP switch A | ||

| drop. |

Feeding speed is switched to high speed.

* <BAS-311F-L only>

If using the work clamp and sewing data for the older

Old | +120 mm |

New | +110 mm |

Note

The break of the sewing pattern is apt to occur in the extended sewing area.

55