5. INSTALLATION

5-5. Replacing the bobbin case and threading the thread

![]() CAUTION

CAUTION

If the power switch needs to be left on when carrying out replacing the bobbin, be extremely careful to observe all safety precautions.

The machine may operate if the foot switch is depressed by mistake, which could result in injury. (ex. Continuing sewing from a stopping point)

(3) | (2) | 30 mm | |

(4) | |||

|

|

(1)

1201S | 0110Q | 1202S |

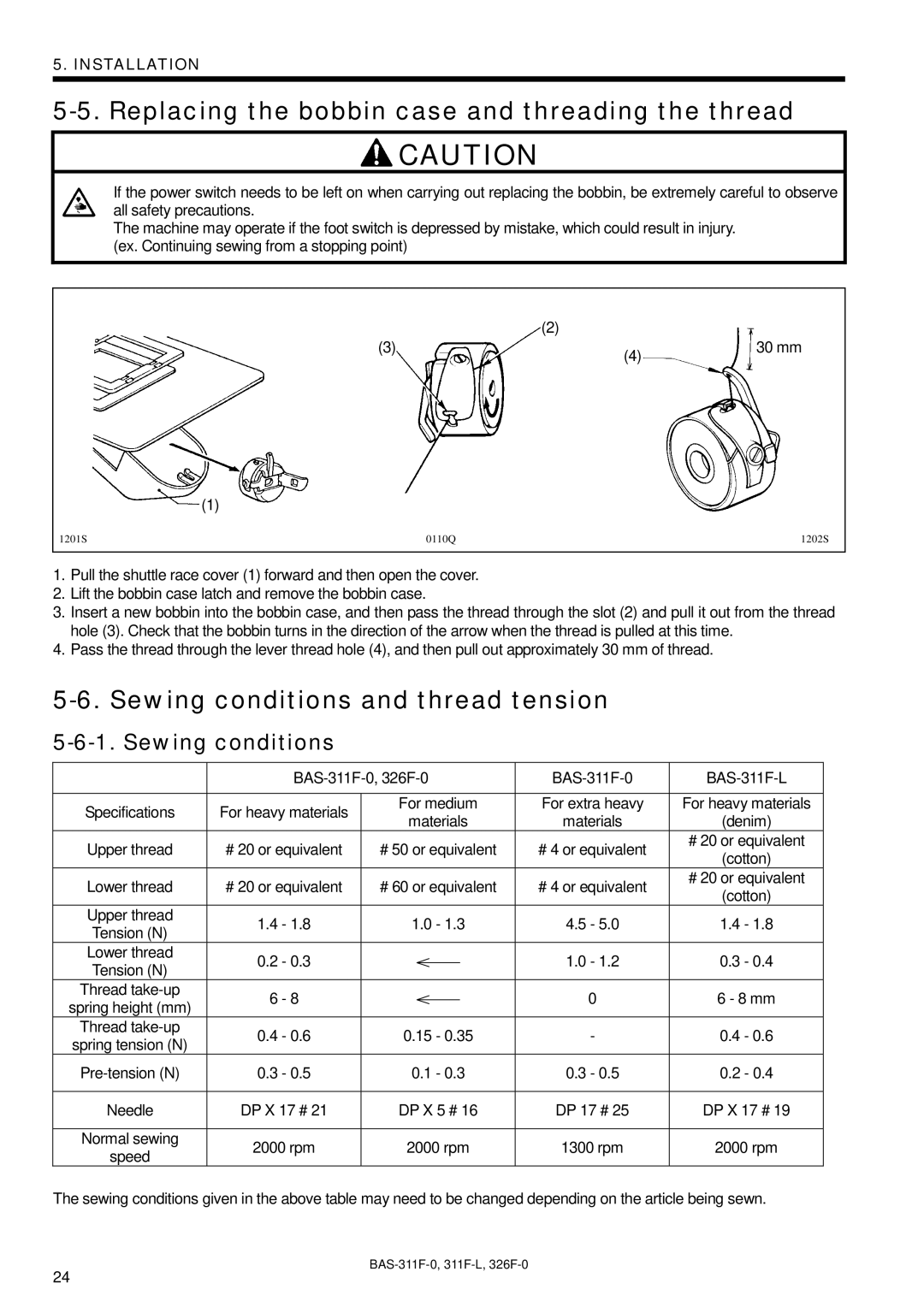

1.Pull the shuttle race cover (1) forward and then open the cover.

2.Lift the bobbin case latch and remove the bobbin case.

3.Insert a new bobbin into the bobbin case, and then pass the thread through the slot (2) and pull it out from the thread hole (3). Check that the bobbin turns in the direction of the arrow when the thread is pulled at this time.

4.Pass the thread through the lever thread hole (4), and then pull out approximately 30 mm of thread.

5-6. Sewing conditions and thread tension

5-6-1. Sewing conditions

| |||||

|

|

|

|

| |

Specifications | For heavy materials | For medium | For extra heavy | For heavy materials | |

materials | materials | (denim) | |||

|

| ||||

Upper thread | # 20 or equivalent | # 50 or equivalent | # 4 or equivalent | # 20 or equivalent | |

(cotton) | |||||

|

|

|

| ||

Lower thread | # 20 or equivalent | # 60 or equivalent | # 4 or equivalent | # 20 or equivalent | |

(cotton) | |||||

|

|

|

| ||

Upper thread | 1.4 - 1.8 | 1.0 - 1.3 | 4.5 - 5.0 | 1.4 - 1.8 | |

Tension (N) | |||||

|

|

|

| ||

Lower thread | 0.2 - 0.3 |

| 1.0 - 1.2 | 0.3 - 0.4 | |

Tension (N) |

| ||||

|

|

|

| ||

Thread | 6 - 8 |

| 0 | 6 - 8 mm | |

spring height (mm) |

| ||||

|

|

|

| ||

Thread | 0.4 - 0.6 | 0.15 - 0.35 | - | 0.4 - 0.6 | |

spring tension (N) | |||||

|

|

|

| ||

0.3 - 0.5 | 0.1 - 0.3 | 0.3 - 0.5 | 0.2 - 0.4 | ||

|

|

|

|

| |

Needle | DP X 17 # 21 | DP X 5 # 16 | DP 17 # 25 | DP X 17 # 19 | |

|

|

|

|

| |

Normal sewing | 2000 rpm | 2000 rpm | 1300 rpm | 2000 rpm | |

speed | |||||

|

|

|

| ||

The sewing conditions given in the above table may need to be changed depending on the article being sewn.

24