valve shall be tested for leaks.

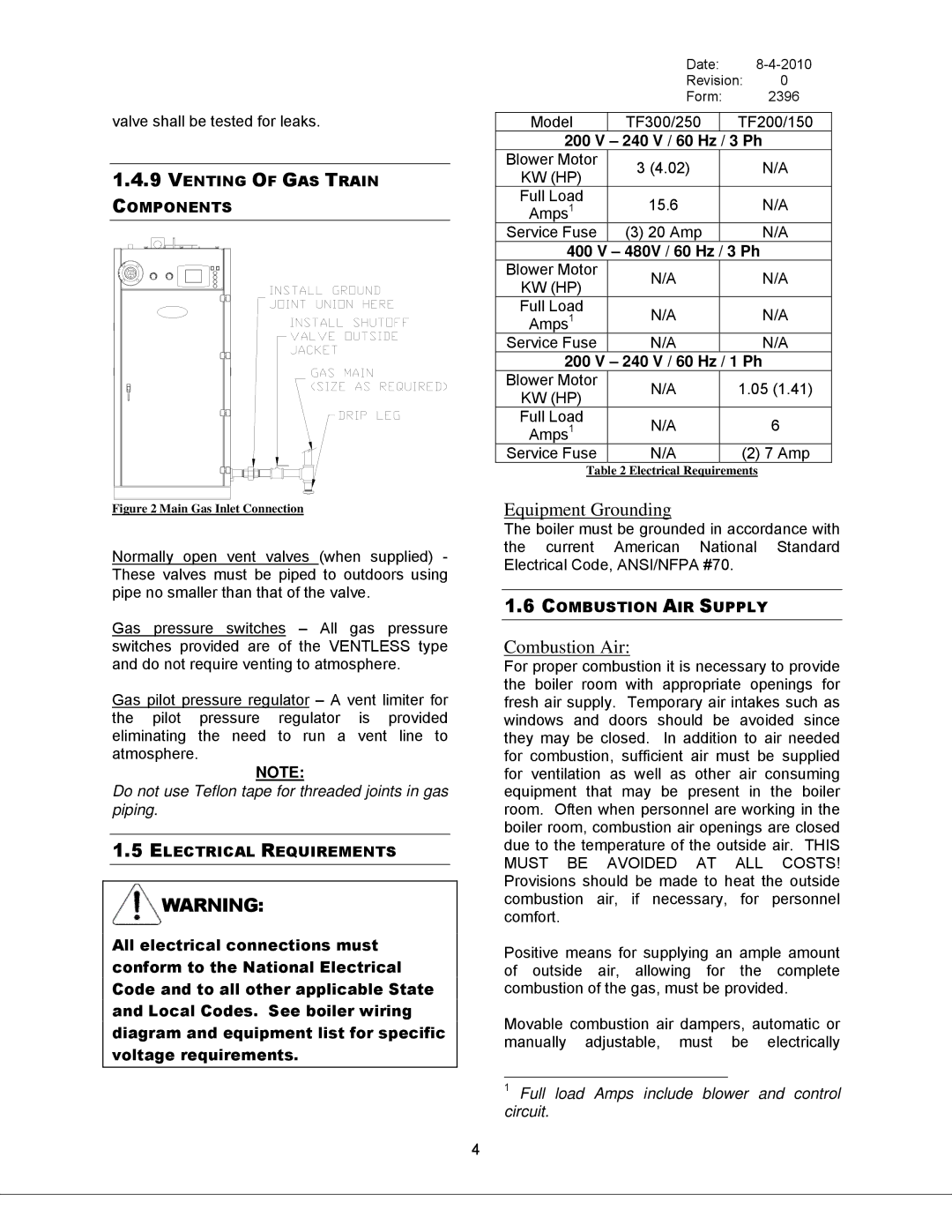

1.4.9VENTING OF GAS TRAIN COMPONENTS

Figure 2 Main Gas Inlet Connection

Normally open vent valves (when supplied) - These valves must be piped to outdoors using pipe no smaller than that of the valve.

Gas pressure switches – All gas pressure switches provided are of the VENTLESS type and do not require venting to atmosphere.

Gas pilot pressure regulator – A vent limiter for the pilot pressure regulator is provided eliminating the need to run a vent line to atmosphere.

NOTE:

Do not use Teflon tape for threaded joints in gas piping.

1.5ELECTRICAL REQUIREMENTS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() WARNING:

WARNING:

All electrical connections must conform to the National Electrical Code and to all other applicable State and Local Codes. See boiler wiring diagram and equipment list for specific voltage requirements.

| Date: | |||

| Revision: | 0 | ||

| Form: |

| 2396 | |

|

|

|

| |

Model | TF300/250 |

| TF200/150 | |

200 V | – 240 V / 60 Hz | / 3 Ph |

| |

Blower Motor | 3 (4.02) |

|

| N/A |

KW (HP) |

|

| ||

|

|

|

| |

Full Load | 15.6 |

|

| N/A |

Amps1 |

|

| ||

Service Fuse | (3) 20 Amp |

|

| N/A |

400 V | – 480V / 60 Hz | / 3 Ph |

| |

Blower Motor | N/A |

|

| N/A |

KW (HP) |

|

| ||

|

|

|

| |

Full Load | N/A |

|

| N/A |

Amps1 |

|

| ||

Service Fuse | N/A |

|

| N/A |

200 V | – 240 V / 60 Hz | / 1 Ph |

| |

Blower Motor | N/A |

| 1.05 (1.41) | |

KW (HP) |

| |||

|

|

|

| |

Full Load | N/A |

|

| 6 |

Amps1 |

|

| ||

Service Fuse | N/A |

| (2) 7 Amp | |

Table 2 Electrical Requirements |

| |||

Equipment Grounding

The boiler must be grounded in accordance with the current American National Standard Electrical Code, ANSI/NFPA #70.

1.6COMBUSTION AIR SUPPLY

Combustion Air:

For proper combustion it is necessary to provide the boiler room with appropriate openings for fresh air supply. Temporary air intakes such as windows and doors should be avoided since they may be closed. In addition to air needed for combustion, sufficient air must be supplied for ventilation as well as other air consuming equipment that may be present in the boiler room. Often when personnel are working in the boiler room, combustion air openings are closed due to the temperature of the outside air. THIS MUST BE AVOIDED AT ALL COSTS! Provisions should be made to heat the outside combustion air, if necessary, for personnel comfort.

Positive means for supplying an ample amount of outside air, allowing for the complete combustion of the gas, must be provided.

Movable combustion air dampers, automatic or manually adjustable, must be electrically

1 Full load Amps include blower and control circuit.

4