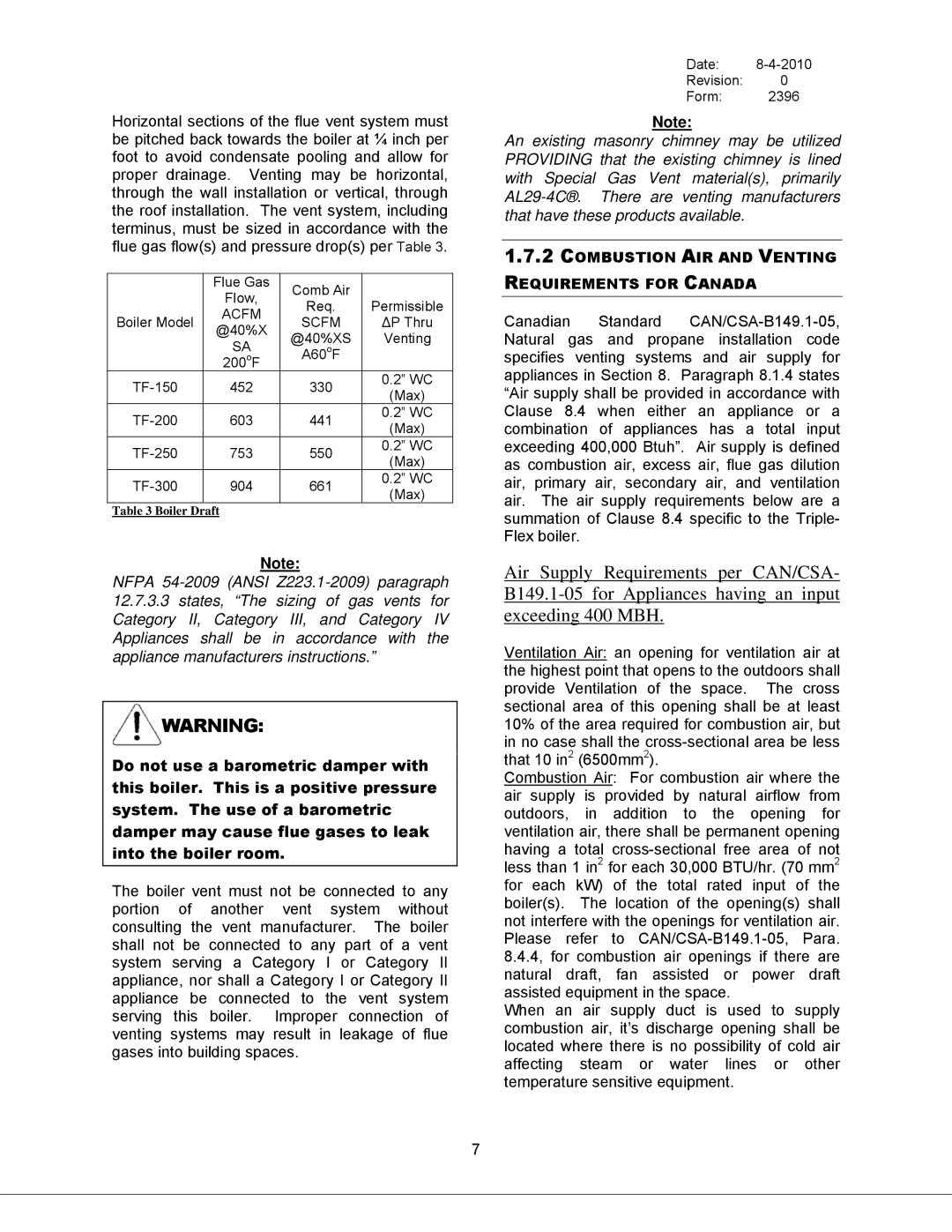

Horizontal sections of the flue vent system must be pitched back towards the boiler at ¼ inch per foot to avoid condensate pooling and allow for proper drainage. Venting may be horizontal, through the wall installation or vertical, through the roof installation. The vent system, including terminus, must be sized in accordance with the flue gas flow(s) and pressure drop(s) per Table 3.

| Flue Gas | Comb Air |

| |

| Flow, |

| ||

| Req. | Permissible | ||

| ACFM | |||

Boiler Model | SCFM | ∆P Thru | ||

@40%X | ||||

| @40%XS | Venting | ||

| SA | |||

| o |

| ||

| 200oF | A60 F |

| |

452 | 330 | 0.2” WC | ||

(Max) | ||||

|

|

| ||

603 | 441 | 0.2” WC | ||

(Max) | ||||

|

|

| ||

753 | 550 | 0.2” WC | ||

(Max) | ||||

|

|

| ||

904 | 661 | 0.2” WC | ||

(Max) | ||||

|

|

| ||

Table 3 Boiler Draft |

|

| ||

Note:

NFPA

12.7.3.3states, “The sizing of gas vents for Category II, Category III, and Category IV Appliances shall be in accordance with the appliance manufacturers instructions.”

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() WARNING:

WARNING:

Do not use a barometric damper with this boiler. This is a positive pressure system. The use of a barometric damper may cause flue gases to leak into the boiler room.

The boiler vent must not be connected to any portion of another vent system without consulting the vent manufacturer. The boiler shall not be connected to any part of a vent system serving a Category I or Category II appliance, nor shall a Category I or Category II appliance be connected to the vent system serving this boiler. Improper connection of venting systems may result in leakage of flue gases into building spaces.

7

Date: 8-4-2010

Revision: 0

Form: 2396

Note:

An existing masonry chimney may be utilized PROVIDING that the existing chimney is lined with Special Gas Vent material(s), primarily

1.7.2COMBUSTION AIR AND VENTING REQUIREMENTS FOR CANADA

Canadian Standard

Air Supply Requirements per CAN/CSA-

Ventilation Air: an opening for ventilation air at the highest point that opens to the outdoors shall provide Ventilation of the space. The cross sectional area of this opening shall be at least 10% of the area required for combustion air, but in no case shall the

Combustion Air: For combustion air where the air supply is provided by natural airflow from outdoors, in addition to the opening for ventilation air, there shall be permanent opening having a total

When an air supply duct is used to supply combustion air, it’s discharge opening shall be located where there is no possibility of cold air affecting steam or water lines or other temperature sensitive equipment.