|

|

|

| Date: | ||

|

|

|

| Revision: |

| 0 |

|

|

|

| Form: | 2396 | |

|

|

|

|

| ||

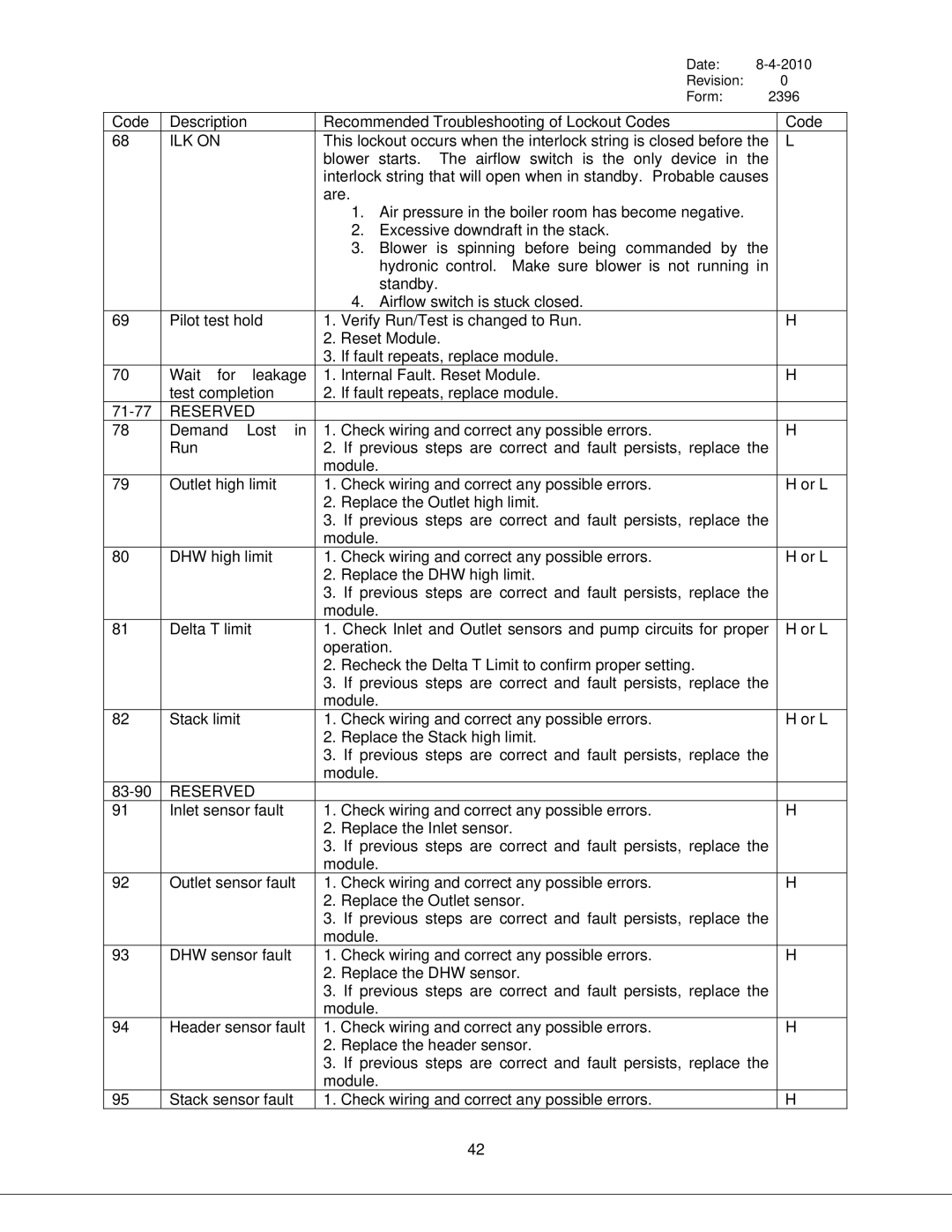

Code | Description | Recommended Troubleshooting of Lockout Codes |

| Code | ||

68 | ILK ON |

| This lockout occurs when the interlock string is closed before the | L | ||

|

|

| blower starts. The airflow switch is the only device in the |

| ||

|

|

| interlock string that will open when in standby. Probable causes |

| ||

|

|

| are. |

|

| |

|

|

|

| 1. Air pressure in the boiler room has become negative. |

|

|

|

|

|

| 2. Excessive downdraft in the stack. |

|

|

|

|

|

| 3. Blower is spinning before being commanded by the |

| |

|

|

|

| hydronic control. Make sure blower is not running in |

| |

|

|

|

| standby. |

|

|

|

|

|

| 4. Airflow switch is stuck closed. |

|

|

69 | Pilot test hold | 1. Verify Run/Test is changed to Run. |

| H | ||

|

|

| 2. | Reset Module. |

|

|

|

|

| 3. | If fault repeats, replace module. |

|

|

70 | Wait for | leakage | 1. Internal Fault. Reset Module. |

| H | |

| test completion | 2. If fault repeats, replace module. |

|

| ||

RESERVED |

|

|

|

| ||

78 | Demand | Lost in | 1. Check wiring and correct any possible errors. |

| H | |

| Run |

| 2. If previous steps are correct and fault persists, replace the |

| ||

|

|

| module. |

|

| |

79 | Outlet high limit | 1. Check wiring and correct any possible errors. |

| H or L | ||

|

|

| 2. | Replace the Outlet high limit. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

80 | DHW high limit | 1. Check wiring and correct any possible errors. |

| H or L | ||

|

|

| 2. | Replace the DHW high limit. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

81 | Delta T limit | 1. Check Inlet and Outlet sensors and pump circuits for proper | H or L | |||

|

|

| operation. |

|

| |

|

|

| 2. | Recheck the Delta T Limit to confirm proper setting. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

82 | Stack limit |

| 1. Check wiring and correct any possible errors. |

| H or L | |

|

|

| 2. | Replace the Stack high limit. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

RESERVED |

|

|

|

| ||

91 | Inlet sensor fault | 1. Check wiring and correct any possible errors. |

| H | ||

|

|

| 2. | Replace the Inlet sensor. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

92 | Outlet sensor fault | 1. Check wiring and correct any possible errors. |

| H | ||

|

|

| 2. | Replace the Outlet sensor. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

93 | DHW sensor fault | 1. Check wiring and correct any possible errors. |

| H | ||

|

|

| 2. | Replace the DHW sensor. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

94 | Header sensor fault | 1. Check wiring and correct any possible errors. |

| H | ||

|

|

| 2. | Replace the header sensor. |

|

|

|

|

| 3. | If previous steps are correct and fault persists, replace the |

| |

|

|

| module. |

|

| |

95 | Stack sensor fault | 1. Check wiring and correct any possible errors. |

| H | ||

|

|

|

| 42 |

|

|