Gas |

|

|

|

| |

Manifold | 4.4 | 3.6 | 4.0 | 2.0 | |

Pressure | |||||

|

|

|

| ||

(IWC) |

|

|

|

| |

Max RPM | 6000- | 5100- | 3550- | 2700- | |

7000 | 5500 | 4200 | 2850 | ||

| |||||

Low Fire |

|

|

|

| |

Gas |

|

|

|

| |

Manifold | .3 | .3 | .2 | .2 | |

Pressure | |||||

|

|

|

| ||

(IWC) |

|

|

|

| |

Min RPM | 1200- | 1200- | 800- | 800- | |

1600 | 1600 | 950 | 950 | ||

|

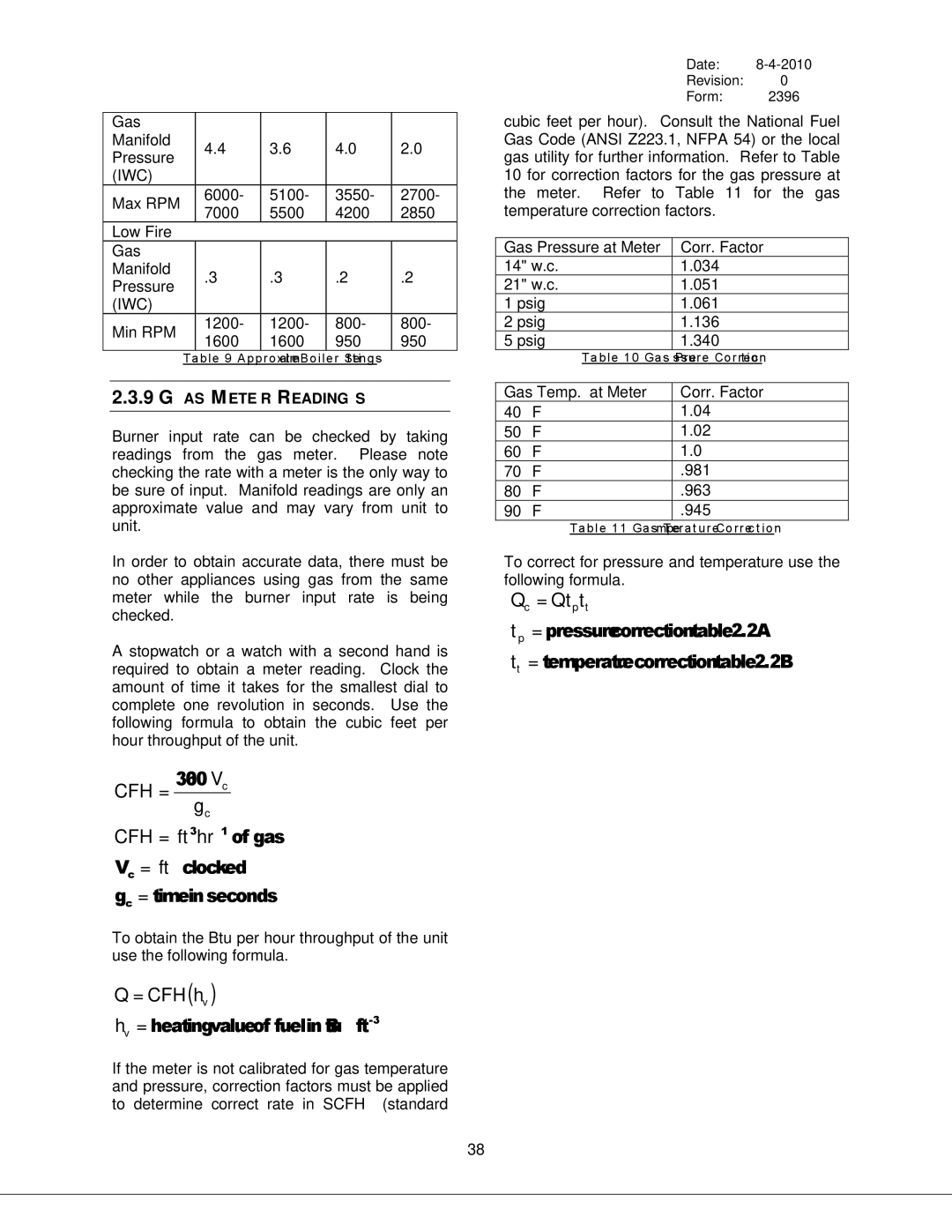

Table 9 Approximate Boiler Settings

2.3.9GAS METER READINGS

Burner input rate can be checked by taking readings from the gas meter. Please note checking the rate with a meter is the only way to be sure of input. Manifold readings are only an approximate value and may vary from unit to unit.

In order to obtain accurate data, there must be no other appliances using gas from the same meter while the burner input rate is being checked.

A stopwatch or a watch with a second hand is required to obtain a meter reading. Clock the amount of time it takes for the smallest dial to complete one revolution in seconds. Use the following formula to obtain the cubic feet per hour throughput of the unit.

CFH = 3600Vc gc

CFH = ft 3 hr −1 of gas Vc = ft clocked

gc = time in seconds

To obtain the Btu per hour throughput of the unit use the following formula.

Q = CFH (hv )

hv = heating value of fuel in Btu ft -3

Date: 8-4-2010

Revision: 0

Form: 2396

cubic feet per hour). Consult the National Fuel Gas Code (ANSI Z223.1, NFPA 54) or the local gas utility for further information. Refer to Table 10 for correction factors for the gas pressure at the meter. Refer to Table 11 for the gas temperature correction factors.

Gas Pressure at Meter | Corr. Factor |

14" w.c. | 1.034 |

21" w.c. | 1.051 |

1 psig | 1.061 |

2 psig | 1.136 |

5 psig | 1.340 |

Table 10 Gas Pressure Correction | |

|

|

Gas Temp. at Meter | Corr. Factor |

40 °F | 1.04 |

50 °F | 1.02 |

60 °F | 1.0 |

70 °F | .981 |

80 °F | .963 |

90 °F | .945 |

Table 11 Gas Temperature Correction

To correct for pressure and temperature use the following formula.

Qc = Qt p tt

t p = pressure correction table 2.2A

tt = temperature correction table 2.2B

If the meter is not calibrated for gas temperature and pressure, correction factors must be applied to determine correct rate in SCFH (standard

38