Safety Considerations

Contents

General

Installation

Physical Data 50PTH, PTV, PTD026-072 Units

50PTH026-072 Dimensional Data

Aux Electric Heat Disconnect

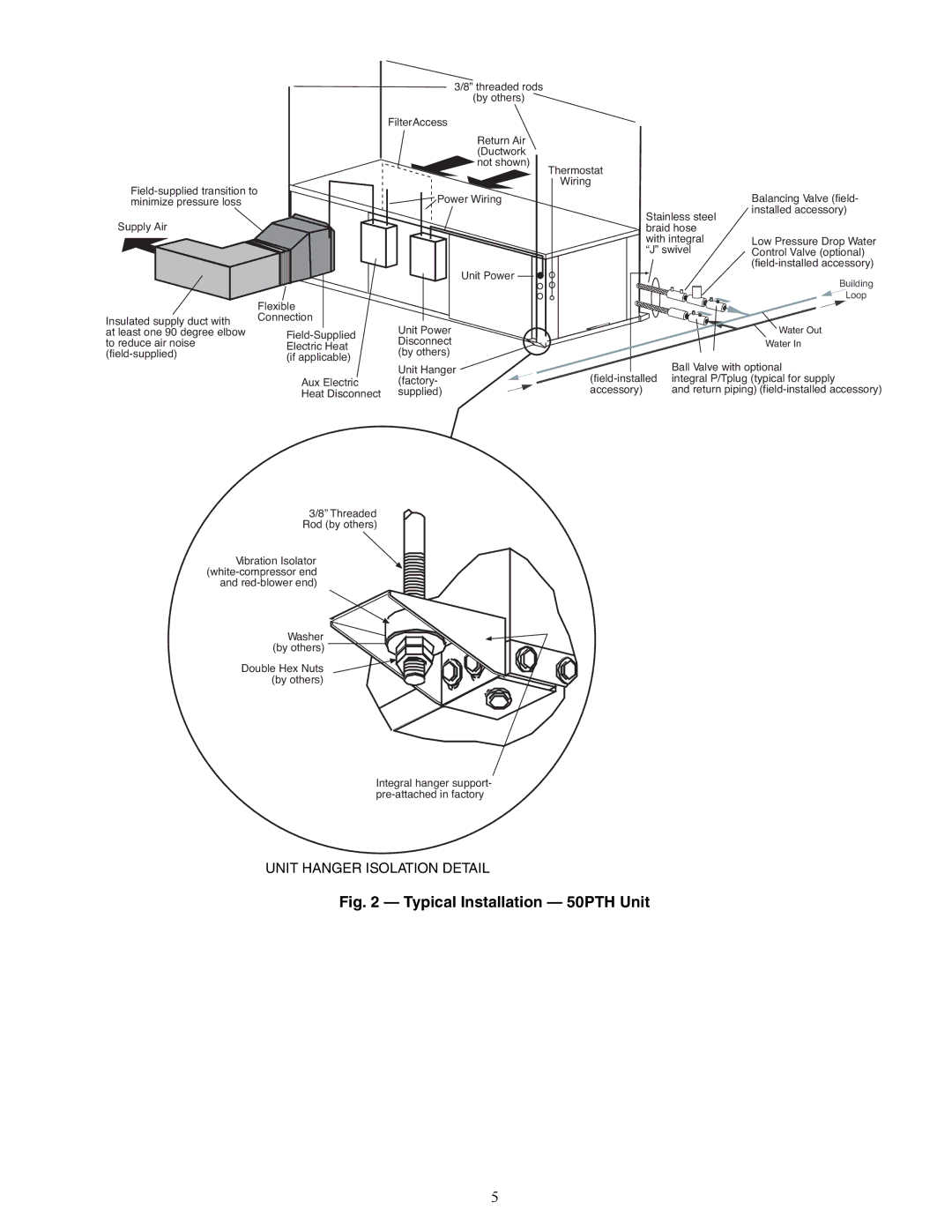

Typical Installation 50PTH Unit

50PTV Dimensional Data

50PTD Dimensional Data

Back Discharge

Side Discharge

Mount the Unit

Install Condensate Drain

Rotate

Move to Side

Trap Condensate Drain

Horizontal Unit Pitch

Drains field-installed

Typical Ground-Water Piping Installation

Metal Hose Minimum Bend Radii

Wire Field Power Supply

Water Quality Guidelines

50PTH,PTV,PTD Electrical Data

Sensor, Water Coil Freeze Protection

Alarm Relay Contacts

Trans

RVS

ECM

BM ECM

Alarm Relay Contacts

Discharge Temp Switch Relay/Contactor Coil

A50-8363

8364

A50

SPT

LWT

Wshp Open Control

A50-8571

SPT Sensors

Rnet Wiring Specifications

Field-Supplied Sensors for Wshp Open Controller

Rnet Wiring

Wire Field Controls

Wire Terminal

A50-8443

A50-7764tf

A50-8141

A50-8441

A50-8442

Dehumidificaton Mode Settings

Cooling Settings

Heating Settings

CFM Adjust Settings

Blower Performance Data

Wshp Open High Fan Airflow

PRE-START-UP

Wshp Open Fan Only / Low Fan and Med Fan Airflow

Field Selectable Inputs

Complete C Control Jumper Settings

Deluxe D Control Jumper Settings

DIP Switch Block S2 Accessory 2 Relay Options

DIP Switch Block S2 Accessory 1 Relay Options

Humidistat/Dehumidistat Logic Deluxe D DIP Switch Settings

Units with Modulating Hot Water Reheat HWR Option

HWR Operating Modes

Mode Input Output

Operating Limits

START-UP

A50-8145 Water Out

Operating Limits 50PTH, PTV, PTD Units

Water Temperature Change Through Heat Exchanger

Unit Start-Up Cooling Mode

Unit Start-Up Heating Mode

Suction Discharge Super Sub Water Air Temp

A50-8444

Unit Start-Up with Wshp Open Controls

Coaxial Water Pressure Drop

Unit 50PTH, PTV Water Temperature F GPM

PTD

026 038 049

Antifreeze Percentages by Volume

Approximate Fluid Volume gal Per 100 Ft of Pipe

Operation

Units with Aquazone Complete C Control

Units with Wshp Open Multiple Protocol

Page

Page

LED Status Description of Operation Alarm Relay

Complete C Control LED Code Fault Descriptions

LED Fault Description Code

Complete C and Deluxe D Board System Test

Aquazone Deluxe D Control LED Indica

Alarm Relay

Service

Refrigerant Charging

Troubleshooting

Air Coil Fan Motor Removal

Replacing the Wshp Open Controller’s Bat

80.0

90.0

70.0

KOhm 60.0 50.0

Page

Fault Description Solution

ECM Troubleshooting

A50-8448

ECM Pin Connectors

A50-8447

ECM Troubleshooting Flow Diagram

Good Practices

Wshp Troubleshooting

Fault Heating Cooling Possible Cause Solution

No Fault Code Shown

Code 7 Auto Resetting

Over/Under Voltage

Performance Monitor

High Head Pressure

Temperature in Heating

Low Suction Pressure

Low Discharge Air

Alarm Status

Appendix a Wshp Open Screen Configuration

Status

Sensor

Maintenance

Appendix a Wshp Open Screen Configuration

System Settings

Configuration

Schedule

Test

Appendix a Wshp Screen Open Configuration

Service

Screen Name

Configuration Service

Point Name Password Editable Range Default Level

Alarm

Page

Page

Copyright 2010 Carrier Corporation

II. START-UP

50PTH,PTV,PTD START-UP Checklist

Cooling Cycle Analysis

Heating Cycle Analysis

A50-8449

A50-8450

![]() Power Wiring

Power Wiring![]()

![]()

![]()

![]() Loop

Loop![]() Water Out

Water Out