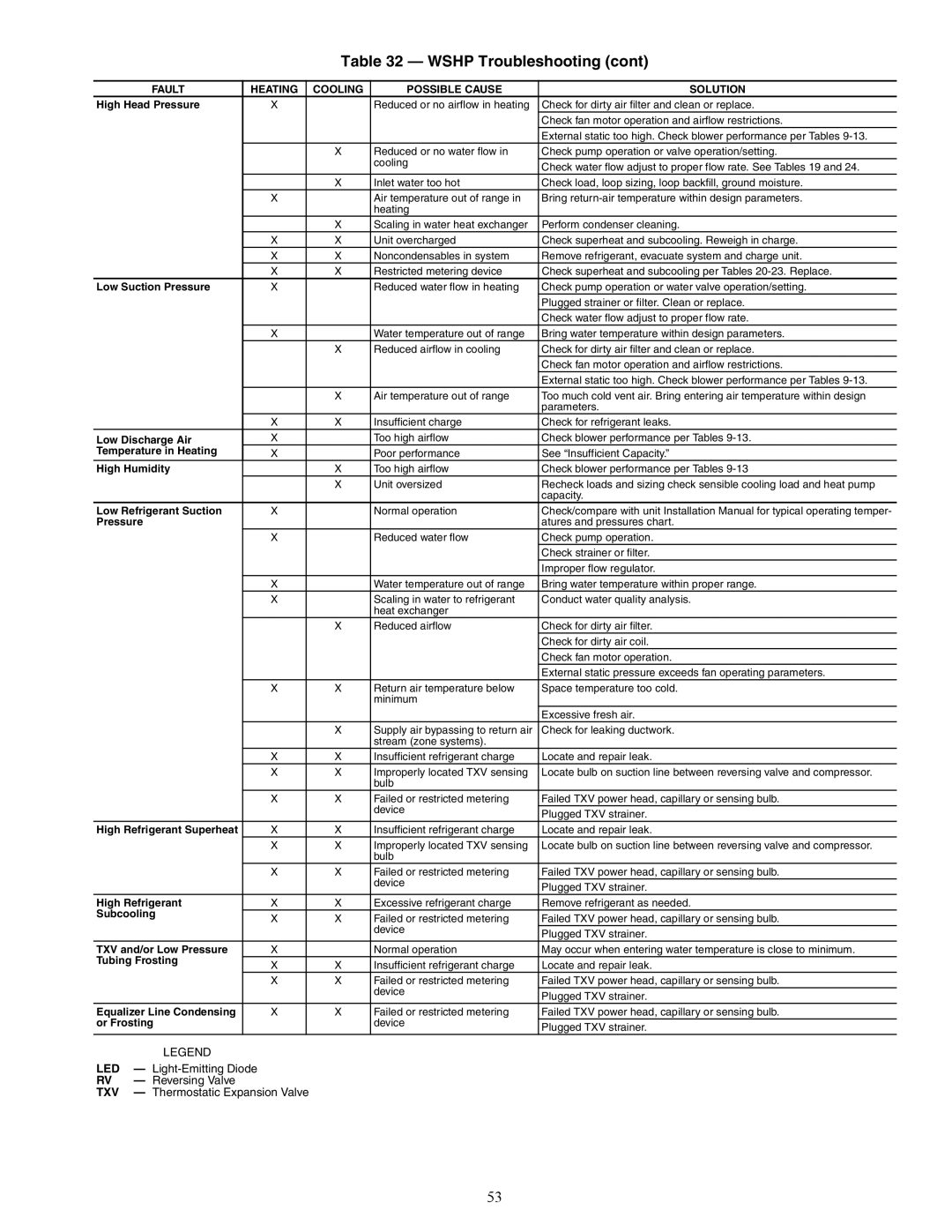

Table 32 — WSHP Troubleshooting (cont)

FAULT | HEATING | COOLING | POSSIBLE CAUSE | SOLUTION | |

High Head Pressure | X |

| Reduced or no airflow in heating | Check for dirty air filter and clean or replace. | |

|

|

|

| Check fan motor operation and airflow restrictions. | |

|

|

|

| External static too high. Check blower performance per Tables | |

|

| X | Reduced or no water flow in | Check pump operation or valve operation/setting. | |

|

|

| cooling | Check water flow adjust to proper flow rate. See Tables 19 and 24. | |

|

|

|

| ||

|

| X | Inlet water too hot | Check load, loop sizing, loop backfill, ground moisture. | |

| X |

| Air temperature out of range in | Bring | |

|

|

| heating |

| |

|

| X | Scaling in water heat exchanger | Perform condenser cleaning. | |

| X | X | Unit overcharged | Check superheat and subcooling. Reweigh in charge. | |

| X | X | Noncondensables in system | Remove refrigerant, evacuate system and charge unit. | |

| X | X | Restricted metering device | Check superheat and subcooling per Tables | |

Low Suction Pressure | X |

| Reduced water flow in heating | Check pump operation or water valve operation/setting. | |

|

|

|

| Plugged strainer or filter. Clean or replace. | |

|

|

|

| Check water flow adjust to proper flow rate. | |

| X |

| Water temperature out of range | Bring water temperature within design parameters. | |

|

| X | Reduced airflow in cooling | Check for dirty air filter and clean or replace. | |

|

|

|

| Check fan motor operation and airflow restrictions. | |

|

|

|

| External static too high. Check blower performance per Tables | |

|

| X | Air temperature out of range | Too much cold vent air. Bring entering air temperature within design | |

|

|

|

| parameters. | |

| X | X | Insufficient charge | Check for refrigerant leaks. | |

Low Discharge Air | X |

| Too high airflow | Check blower performance per Tables | |

Temperature in Heating | X |

| Poor performance | See “Insufficient Capacity.” | |

High Humidity |

| X | Too high airflow | Check blower performance per Tables | |

|

| X | Unit oversized | Recheck loads and sizing check sensible cooling load and heat pump | |

|

|

|

| capacity. | |

Low Refrigerant Suction | X |

| Normal operation | Check/compare with unit Installation Manual for typical operating temper- | |

Pressure |

|

|

| atures and pressures chart. | |

| X |

| Reduced water flow | Check pump operation. | |

|

|

|

| Check strainer or filter. | |

|

|

|

| Improper flow regulator. | |

| X |

| Water temperature out of range | Bring water temperature within proper range. | |

| X |

| Scaling in water to refrigerant | Conduct water quality analysis. | |

|

|

| heat exchanger |

| |

|

| X | Reduced airflow | Check for dirty air filter. | |

|

|

|

| Check for dirty air coil. | |

|

|

|

| Check fan motor operation. | |

|

|

|

| External static pressure exceeds fan operating parameters. | |

| X | X | Return air temperature below | Space temperature too cold. | |

|

|

| minimum |

| |

|

|

|

| Excessive fresh air. | |

|

| X | Supply air bypassing to return air | Check for leaking ductwork. | |

|

|

| stream (zone systems). |

| |

| X | X | Insufficient refrigerant charge | Locate and repair leak. | |

| X | X | Improperly located TXV sensing | Locate bulb on suction line between reversing valve and compressor. | |

|

|

| bulb |

| |

| X | X | Failed or restricted metering | Failed TXV power head, capillary or sensing bulb. | |

|

|

| device | Plugged TXV strainer. | |

|

|

|

| ||

High Refrigerant Superheat | X | X | Insufficient refrigerant charge | Locate and repair leak. | |

| X | X | Improperly located TXV sensing | Locate bulb on suction line between reversing valve and compressor. | |

|

|

| bulb |

| |

| X | X | Failed or restricted metering | Failed TXV power head, capillary or sensing bulb. | |

|

|

| device | Plugged TXV strainer. | |

|

|

|

| ||

High Refrigerant | X | X | Excessive refrigerant charge | Remove refrigerant as needed. | |

Subcooling |

|

|

|

| |

X | X | Failed or restricted metering | Failed TXV power head, capillary or sensing bulb. | ||

| |||||

|

|

| device | Plugged TXV strainer. | |

|

|

|

| ||

TXV and/or Low Pressure | X |

| Normal operation | May occur when entering water temperature is close to minimum. | |

Tubing Frosting |

|

|

|

| |

X | X | Insufficient refrigerant charge | Locate and repair leak. | ||

| |||||

| X | X | Failed or restricted metering | Failed TXV power head, capillary or sensing bulb. | |

|

|

| device | Plugged TXV strainer. | |

|

|

|

| ||

Equalizer Line Condensing | X | X | Failed or restricted metering | Failed TXV power head, capillary or sensing bulb. | |

or Frosting |

|

| device | Plugged TXV strainer. | |

|

|

|

|

LEGEND

LED —

RV — Reversing Valve

TXV — Thermostatic Expansion Valve

53