Operators Manual

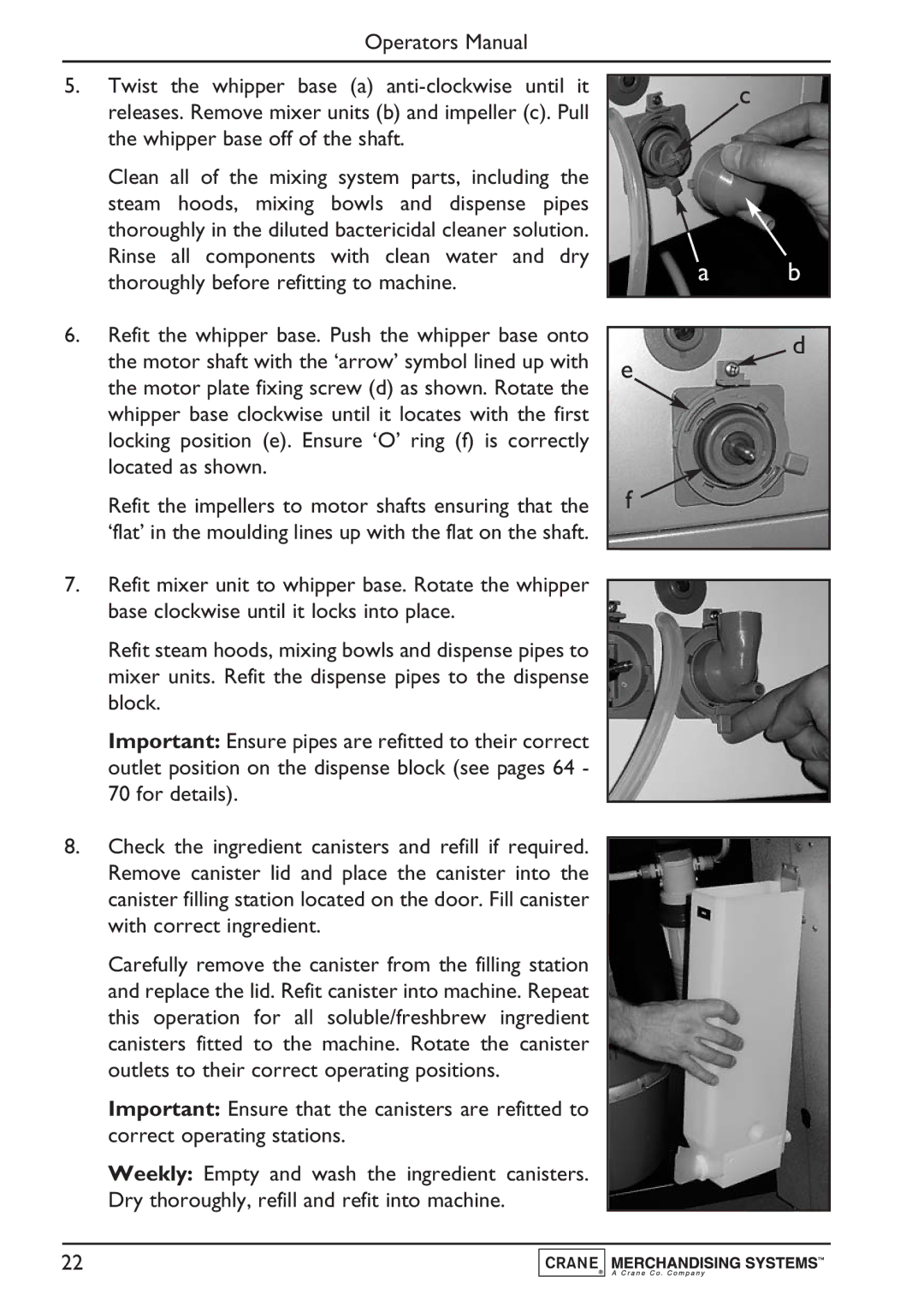

5.Twist the whipper base (a)

Clean all of the mixing system parts, including the steam hoods, mixing bowls and dispense pipes thoroughly in the diluted bactericidal cleaner solution. Rinse all components with clean water and dry thoroughly before refitting to machine.

6.Refit the whipper base. Push the whipper base onto the motor shaft with the ‘arrow’ symbol lined up with the motor plate fixing screw (d) as shown. Rotate the whipper base clockwise until it locates with the first locking position (e). Ensure ‘O’ ring (f) is correctly located as shown.

Refit the impellers to motor shafts ensuring that the ‘flat’ in the moulding lines up with the flat on the shaft.

7.Refit mixer unit to whipper base. Rotate the whipper base clockwise until it locks into place.

Refit steam hoods, mixing bowls and dispense pipes to mixer units. Refit the dispense pipes to the dispense block.

Important: Ensure pipes are refitted to their correct outlet position on the dispense block (see pages 64 - 70 for details).

8.Check the ingredient canisters and refill if required. Remove canister lid and place the canister into the canister filling station located on the door. Fill canister with correct ingredient.

Carefully remove the canister from the filling station and replace the lid. Refit canister into machine. Repeat this operation for all soluble/freshbrew ingredient canisters fitted to the machine. Rotate the canister outlets to their correct operating positions.

Important: Ensure that the canisters are refitted to correct operating stations.

Weekly: Empty and wash the ingredient canisters. Dry thoroughly, refill and refit into machine.

c

a b

d

e

f

22