Operators Manual

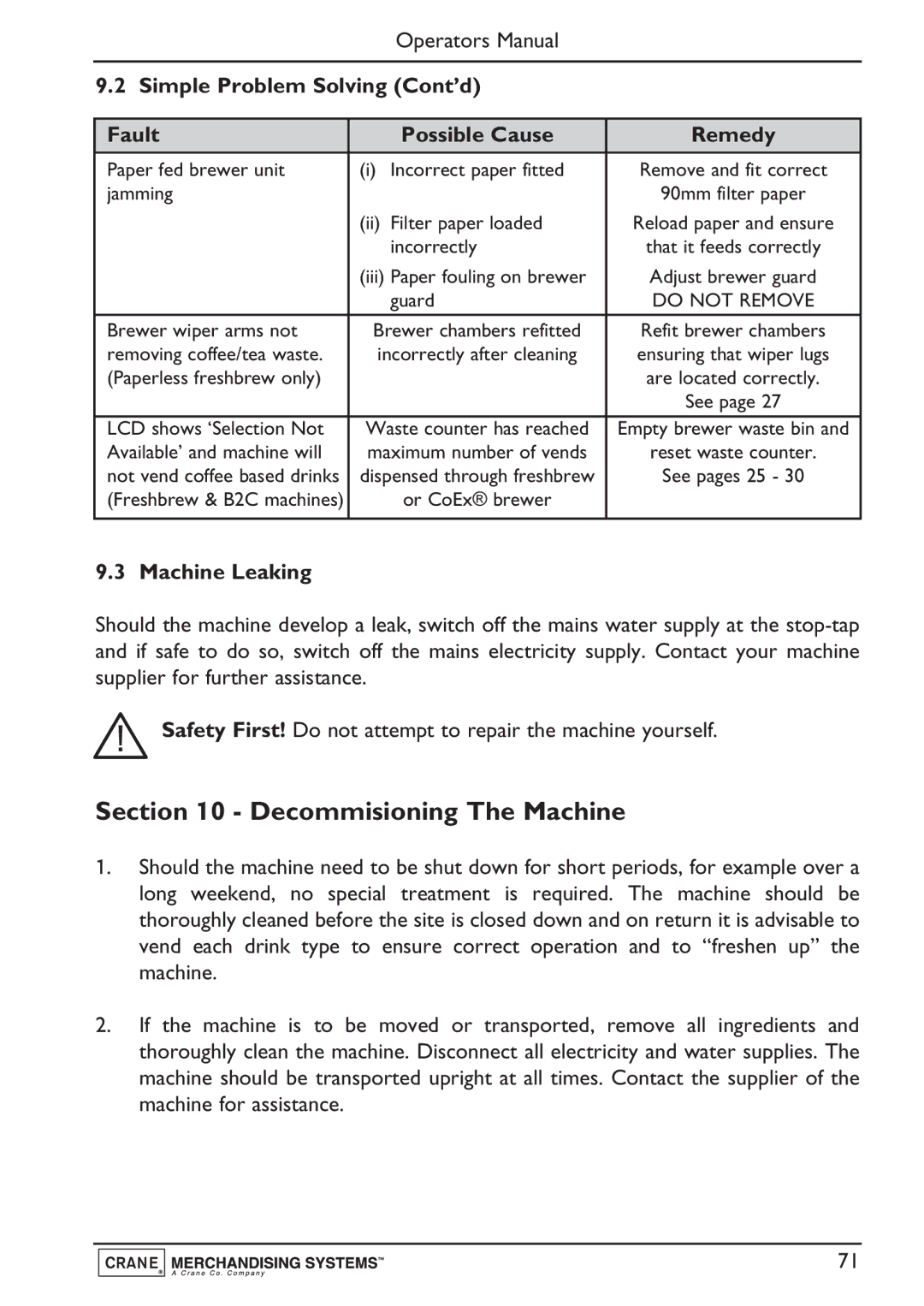

9.2 Simple Problem Solving (Cont’d)

Fault |

| Possible Cause | Remedy |

Paper fed brewer unit | (i) | Incorrect paper fitted | Remove and fit correct |

jamming |

|

| 90mm filter paper |

| (ii) | Filter paper loaded | Reload paper and ensure |

|

| incorrectly | that it feeds correctly |

| (iii) Paper fouling on brewer | Adjust brewer guard | |

|

| guard | DO NOT REMOVE |

Brewer wiper arms not | Brewer chambers refitted | Refit brewer chambers | |

removing coffee/tea waste. | incorrectly after cleaning | ensuring that wiper lugs | |

(Paperless freshbrew only) |

|

| are located correctly. |

|

|

| See page 27 |

|

|

| |

LCD shows ‘Selection Not | Waste counter has reached | Empty brewer waste bin and | |

Available’ and machine will | maximum number of vends | reset waste counter. | |

not vend coffee based drinks | dispensed through freshbrew | See pages 25 - 30 | |

(Freshbrew & B2C machines) |

| or CoEx® brewer |

|

|

|

|

|

9.3 Machine Leaking

Should the machine develop a leak, switch off the mains water supply at the

Safety First! Do not attempt to repair the machine yourself.

Section 10 - Decommisioning The Machine

1.Should the machine need to be shut down for short periods, for example over a long weekend, no special treatment is required. The machine should be thoroughly cleaned before the site is closed down and on return it is advisable to vend each drink type to ensure correct operation and to “freshen up” the machine.

2.If the machine is to be moved or transported, remove all ingredients and thoroughly clean the machine. Disconnect all electricity and water supplies. The machine should be transported upright at all times. Contact the supplier of the machine for assistance.

71