Operators Manual

Important: It is necessary to carry out the cleaning and maintenance procedure outlined on the following pages on a regular basis, either at the end of the day or at the start of the day before the machine is in constant use.

4.5 Cleaning & Filling Procedure - All Machines

1.Fill a cleaning bucket with hot water and dilute the bactericidal cleaner in accordance with the instructions on the product packaging. Open the door of the machine.

2.Rotate canister outlets to upright position. Remove the ingredient canisters. DO NOT place them on the floor.

With a clean, damp sanitised cloth, remove any ingredient build up on the exterior of the canisters, paying particular attention to the area around the canister outlets. Ensure canister outlets are dried thoroughly after cleaning.

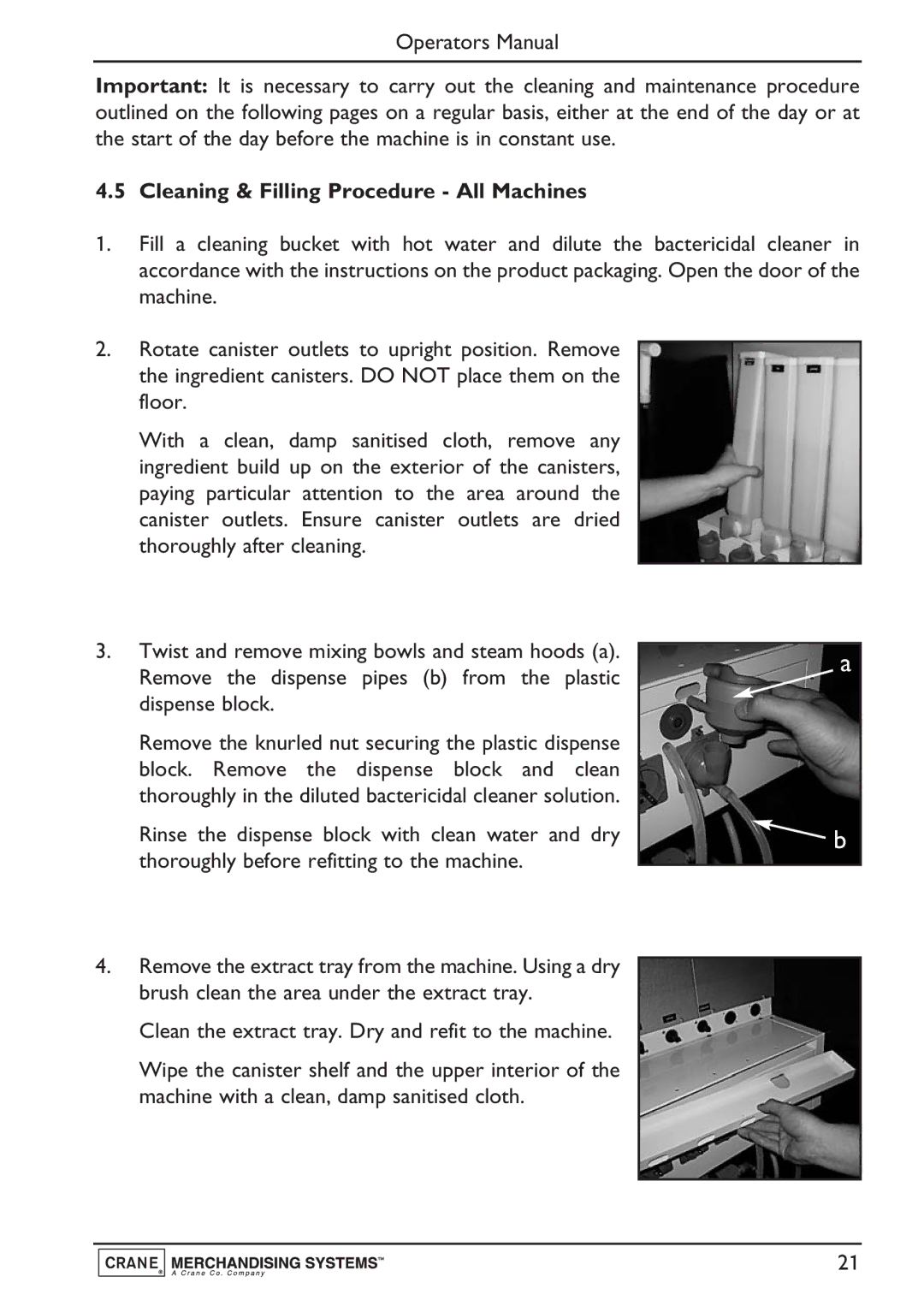

3.Twist and remove mixing bowls and steam hoods (a). Remove the dispense pipes (b) from the plastic dispense block.

Remove the knurled nut securing the plastic dispense block. Remove the dispense block and clean thoroughly in the diluted bactericidal cleaner solution.

Rinse the dispense block with clean water and dry thoroughly before refitting to the machine.

4.Remove the extract tray from the machine. Using a dry brush clean the area under the extract tray.

Clean the extract tray. Dry and refit to the machine.

Wipe the canister shelf and the upper interior of the machine with a clean, damp sanitised cloth.

a

![]() b

b

21