Maintenance/inspection item | Procedure |

|

|

Contamination of membrane filter | Replace the filter paper if it has blackened (see (3) in 10.5). |

| If contamination occurs rapidly, then check the |

| gas extractor ((1) in 10.5), conditioner filter ((2) in 10.5), etc. |

|

|

Electronic gas cooler | Check the fan rotation. |

|

|

Temperature controller for NO2/NO converter | Check that the controlled temperature is approx. 220° C (200° C in case |

| of NO/CO analyzer). |

|

|

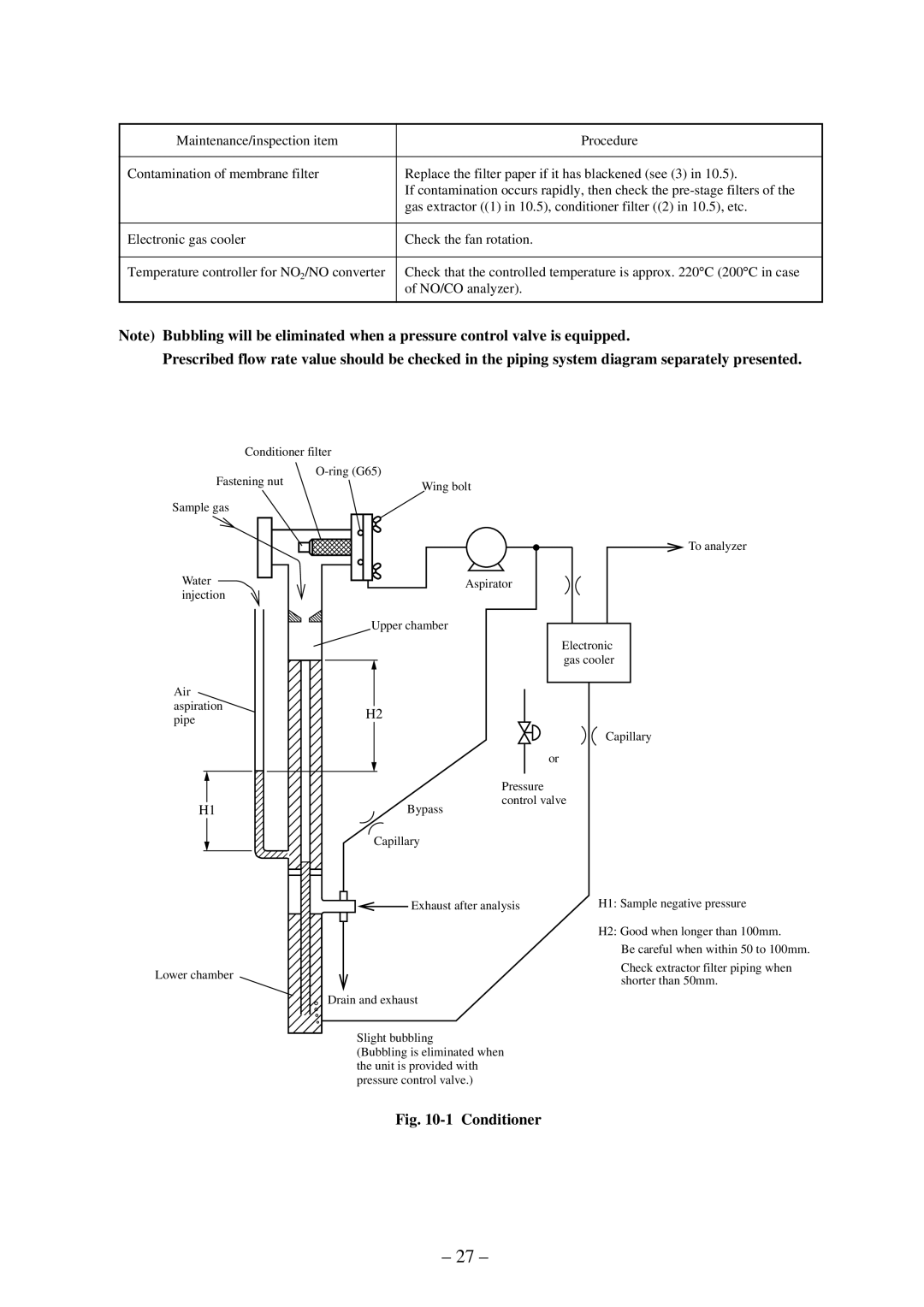

Note) Bubbling will be eliminated when a pressure control valve is equipped.

Prescribed flow rate value should be checked in the piping system diagram separately presented.

Conditioner filter |

|

| |

Fastening nut | Wing bolt |

| |

Sample gas |

|

To analyzer

Water injection

Air aspiration pipe

H1

Aspirator

Upper chamber

Electronic gas cooler

H2

Capillary

or

Pressure

control valve

Bypass

Capillary

Lower chamber

Exhaust after analysis

Drain and exhaust

Slight bubbling

(Bubbling is eliminated when the unit is provided with pressure control valve.)

H1: Sample negative pressure

H2: Good when longer than 100mm.

Be careful when within 50 to 100mm.

Check extractor filter piping when shorter than 50mm.

Fig. 10-1 Conditioner

– 27 –