(5)Check and maintenance of electronic gas cooler

(a)Fan motor

This motor should be replaced periodically every 20,000 hours (about 2 years in case of continuous operation ) as a standard though this varies with operating condition. However, if no abnormality cannot be found at the time of a periodic replacement, the motor is further usable continuously.

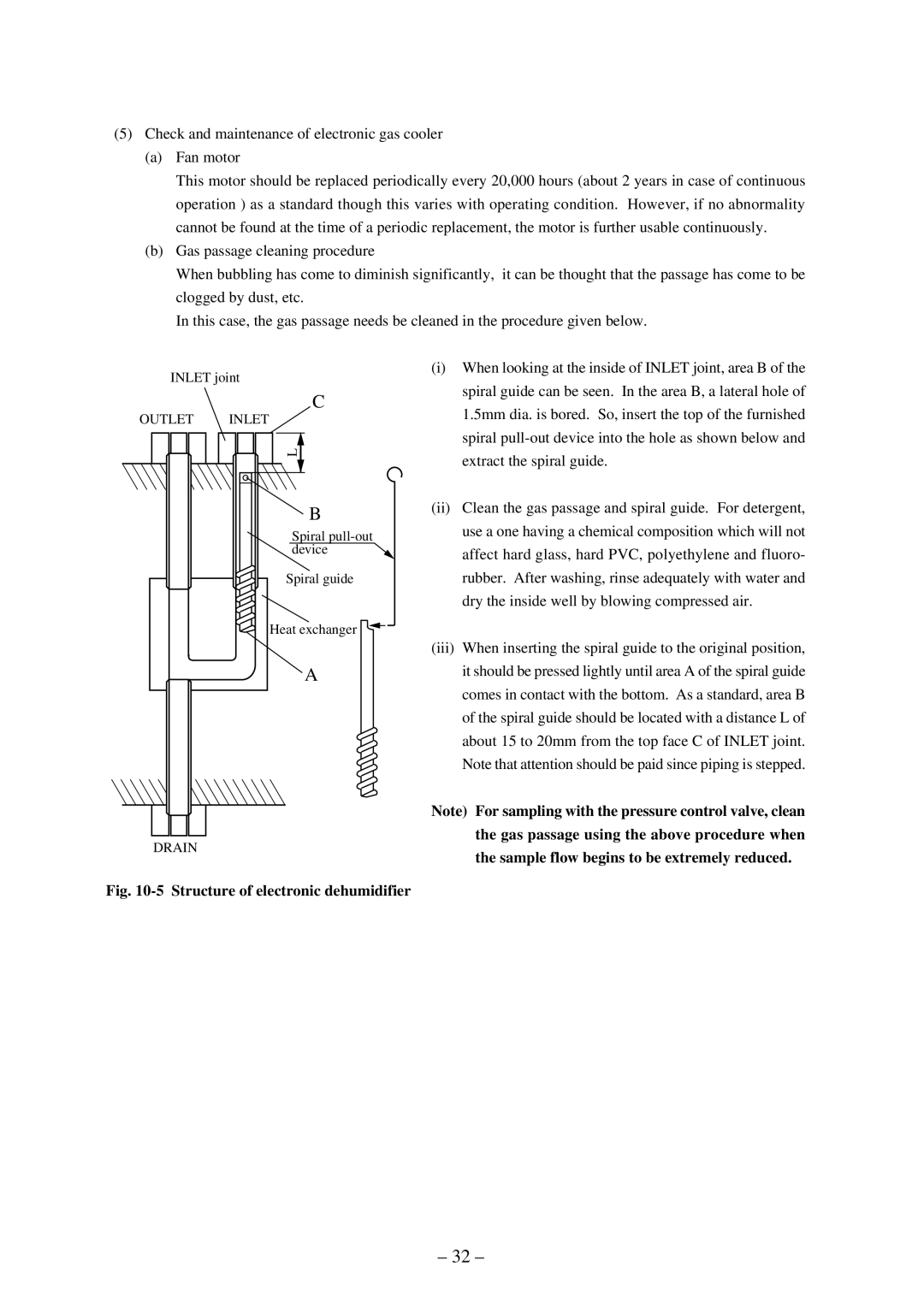

(b)Gas passage cleaning procedure

When bubbling has come to diminish significantly, it can be thought that the passage has come to be clogged by dust, etc.

In this case, the gas passage needs be cleaned in the procedure given below.

INLET joint

C

OUTLET INLET

L

B

Spiral

Spiral guide

Heat exchanger

A

DRAIN

(i)When looking at the inside of INLET joint, area B of the spiral guide can be seen. In the area B, a lateral hole of 1.5mm dia. is bored. So, insert the top of the furnished spiral

(ii)Clean the gas passage and spiral guide. For detergent, use a one having a chemical composition which will not affect hard glass, hard PVC, polyethylene and fluoro- rubber. After washing, rinse adequately with water and dry the inside well by blowing compressed air.

(iii)When inserting the spiral guide to the original position, it should be pressed lightly until area A of the spiral guide comes in contact with the bottom. As a standard, area B of the spiral guide should be located with a distance L of about 15 to 20mm from the top face C of INLET joint. Note that attention should be paid since piping is stepped.

Note) For sampling with the pressure control valve, clean the gas passage using the above procedure when the sample flow begins to be extremely reduced.

Fig. 10-5 Structure of electronic dehumidifier

– 32 –