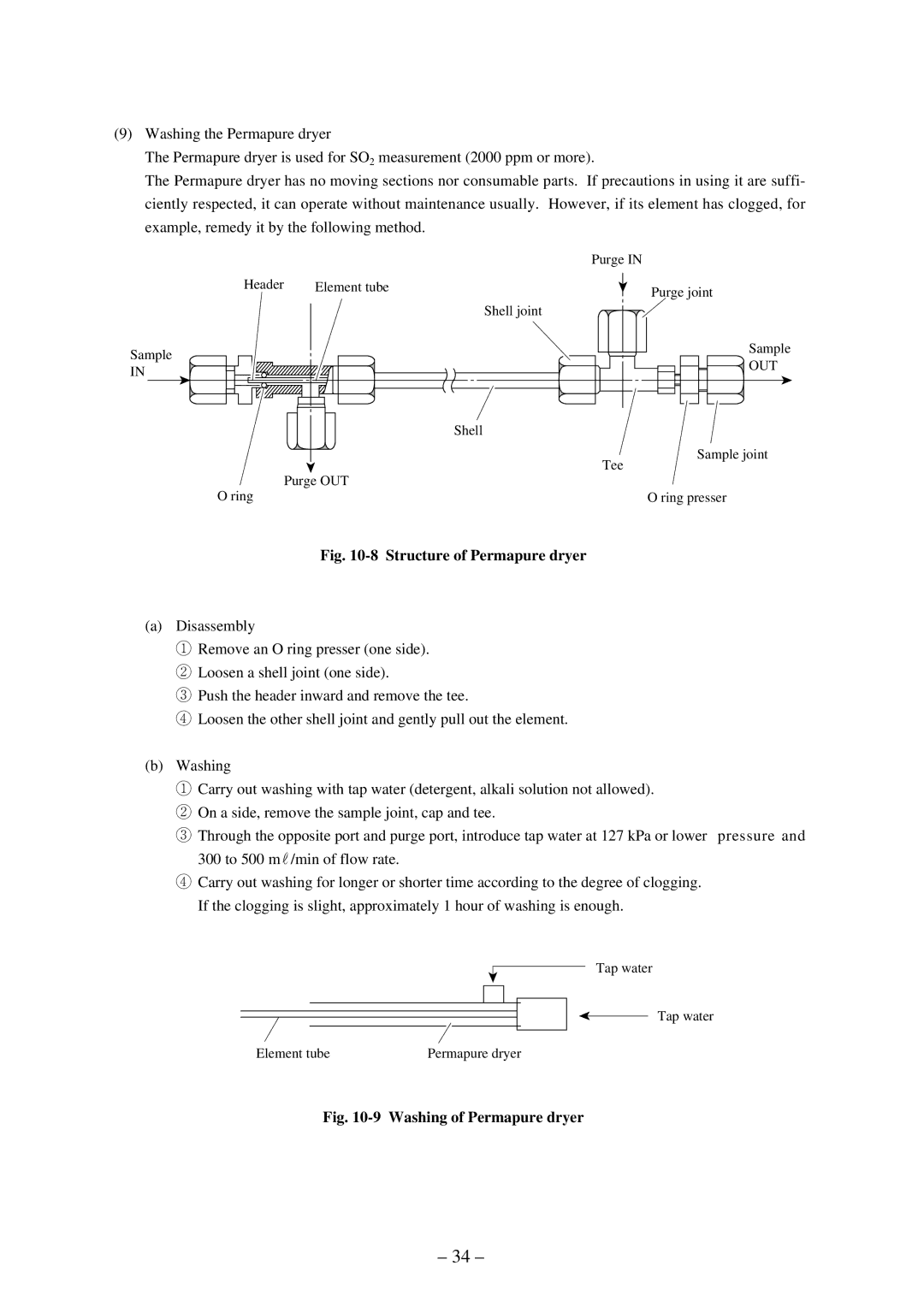

(9)Washing the Permapure dryer

The Permapure dryer is used for SO2 measurement (2000 ppm or more).

The Permapure dryer has no moving sections nor consumable parts. If precautions in using it are suffi- ciently respected, it can operate without maintenance usually. However, if its element has clogged, for example, remedy it by the following method.

Sample

IN

|

| Purge IN |

Header | Element tube | Purge joint |

|

| |

|

| Shell joint |

Sample

![]()

![]()

![]() OUT

OUT

Shell

Sample joint

Tee

Purge OUT

O ring | O ring presser |

Fig. 10-8 Structure of Permapure dryer

(a)Disassembly

q Remove an O ring presser (one side). w Loosen a shell joint (one side).

e Push the header inward and remove the tee.

r Loosen the other shell joint and gently pull out the element.

(b)Washing

q Carry out washing with tap water (detergent, alkali solution not allowed). w On a side, remove the sample joint, cap and tee.

e Through the opposite port and purge port, introduce tap water at 127 kPa or lower pressure and 300 to 500 mN/min of flow rate.

r Carry out washing for longer or shorter time according to the degree of clogging. If the clogging is slight, approximately 1 hour of washing is enough.

Tap water

Tap water

Element tube | Permapure dryer |

Fig. 10-9 Washing of Permapure dryer

– 34 –