![]() WARNING

WARNING

CHECK FOR GAS LEAKS

Explosion Risk

Fire Risk

Asphyxiation Risk

•Check all fittings and connections.

•Do not use open flame.

•After the gas line installation is complete, all connections must be tightened and checked

for leaks with a

Fittings and connections may have loosened during shipping and handling.

Access Through the Valve Assembly

The lower access cover panel is removable if finishing material has not been previously installed.

Remove Media Tray, Burner Assembly, and Base pan. To access components:

1.Remove eleven screws around perimeter of valve plate that secure valve plate to the firebox bottom. See Figure 11.2.

2.Lift the valve plate from the back so that the gas valve can clear the valve plate hole in the bottom the firebox. See Figure 11.3.

Figure 11.2. Remove Valve Plate Screws

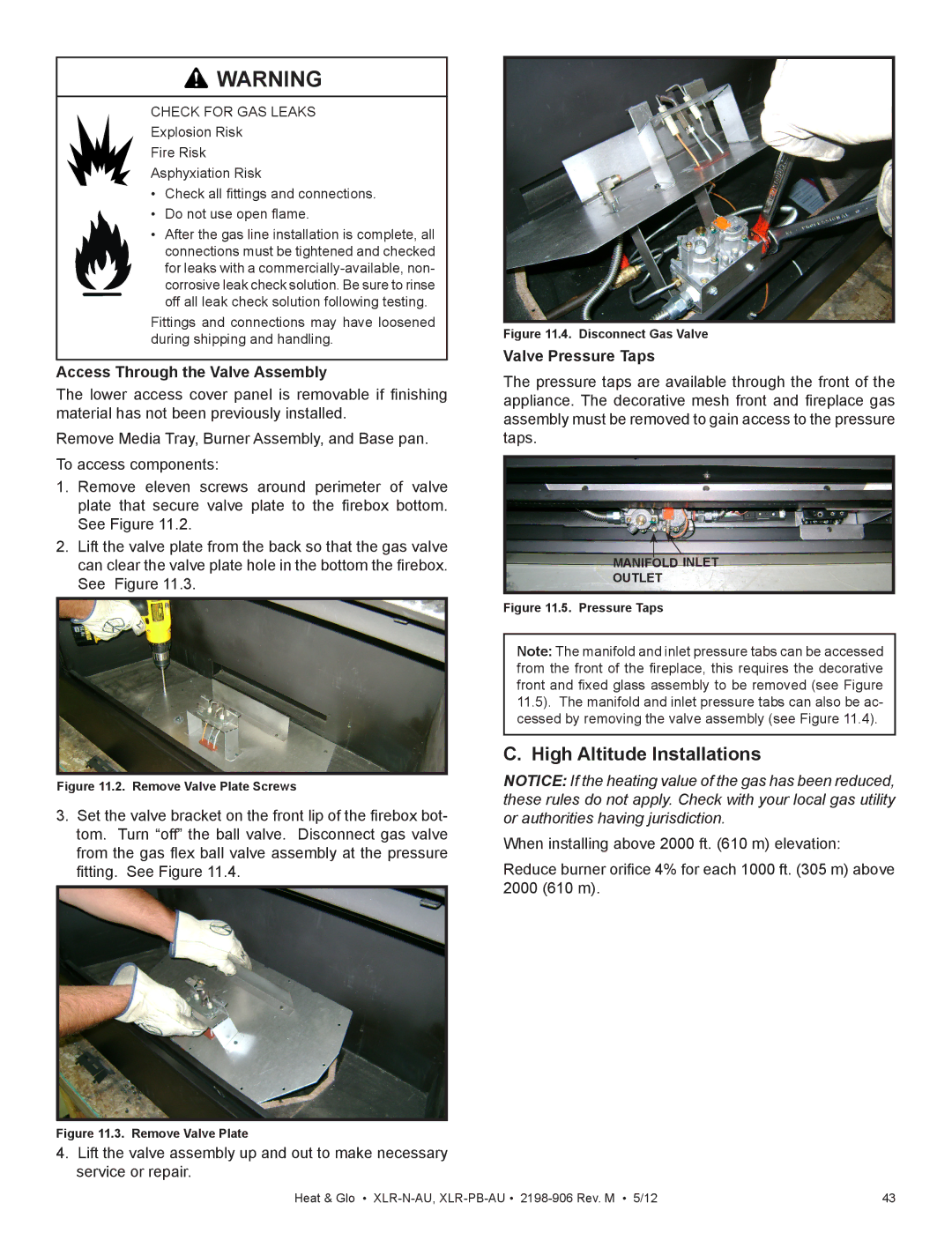

3.Set the valve bracket on the front lip of the firebox bot- tom. Turn “off” the ball valve. Disconnect gas valve from the gas flex ball valve assembly at the pressure fitting. See Figure 11.4.

Figure 11.3. Remove Valve Plate

4.Lift the valve assembly up and out to make necessary service or repair.

Figure 11.4. Disconnect Gas Valve

Valve Pressure Taps

The pressure taps are available through the front of the appliance. The decorative mesh front and fireplace gas assembly must be removed to gain access to the pressure taps.

MANIFOLD INLET

OUTLET

Figure 11.5. Pressure Taps

Note: The manifold and inlet pressure tabs can be accessed from the front of the fireplace, this requires the decorative front and fixed glass assembly to be removed (see Figure 11.5). The manifold and inlet pressure tabs can also be ac- cessed by removing the valve assembly (see Figure 11.4).

C. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced, these rules do not apply. Check with your local gas utility or authorities having jurisdiction.

When installing above 2000 ft. (610 m) elevation:

Reduce burner orifice 4% for each 1000 ft. (305 m) above 2000 (610 m).

Heat & Glo • | 43 |