CAUTION: If a serious leak develops, shut down the POD immediately and isolate the chilled water cooling system from the site. Contact HP immediately to initiate a field service call. Do not attempt to repair the chilled water cooling system. Attempting to

IMPORTANT: Power down the POD after a leak is detected.

A

To repair a

1.Power down all IT equipment.

2.

3.Repair the leak or contact HP if you are still within your service contract.

Isolable leak detection

An isolable leak is any type of leak that does not occur from the main supply line or the return header. To repair an isolable leak:

1.Inspect the zone indicated on the ECS Status Overview screen. You might need to inspect each zone condensate drain pan to determine the exact location of the leak.

2.Power down the IT equipment in the zone where the leak is located.

3.Determine the affected heat exchanger.

4.Close and danger tag the supply and return valves to the affected heat exchanger.

If the heat affected exchanger cannot be identified, close all the heat exchanger supply and return valves in the affected zone and open one supply valve at a time to determine the location of the leak.

5.Repair the leak or contact HP if you are still within your service contract.

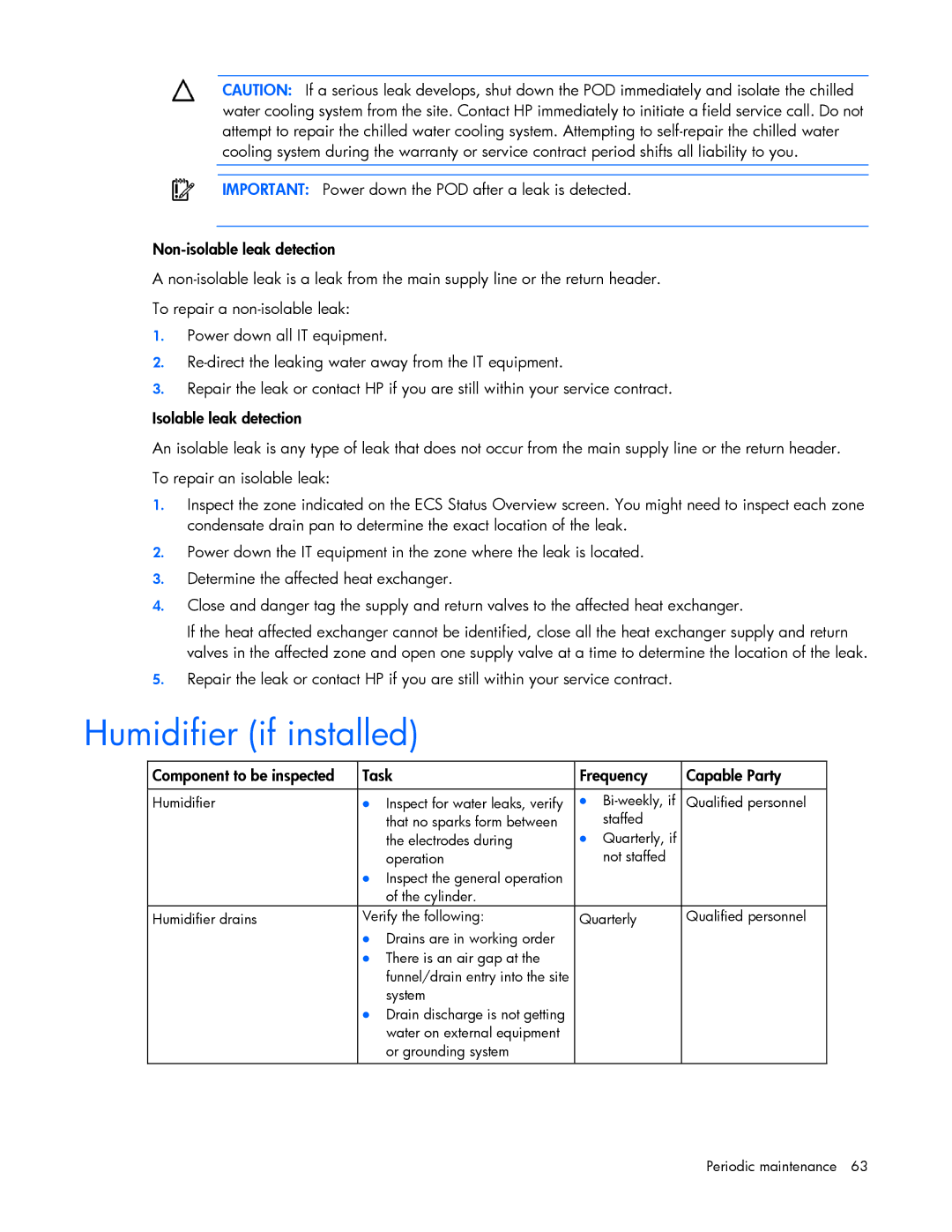

Humidifier (if installed)

Component to be inspected | Task | Frequency | Capable Party | |

|

|

|

|

|

Humidifier | • Inspect for water leaks, verify | • | Qualified personnel | |

| that no sparks form between | • | staffed |

|

| the electrodes during | Quarterly, if |

| |

| operation |

| not staffed |

|

| • Inspect the general operation |

|

|

|

| of the cylinder. |

|

|

|

Humidifier drains | Verify the following: | Quarterly | Qualified personnel | |

| • Drains are in working order |

|

|

|

| • There is an air gap at the |

|

|

|

| funnel/drain entry into the site |

|

|

|

| system |

|

|

|

| • Drain discharge is not getting |

|

|

|

| water on external equipment |

|

|

|

| or grounding system |

|

|

|

|

|

|

|

|

Periodic maintenance 63