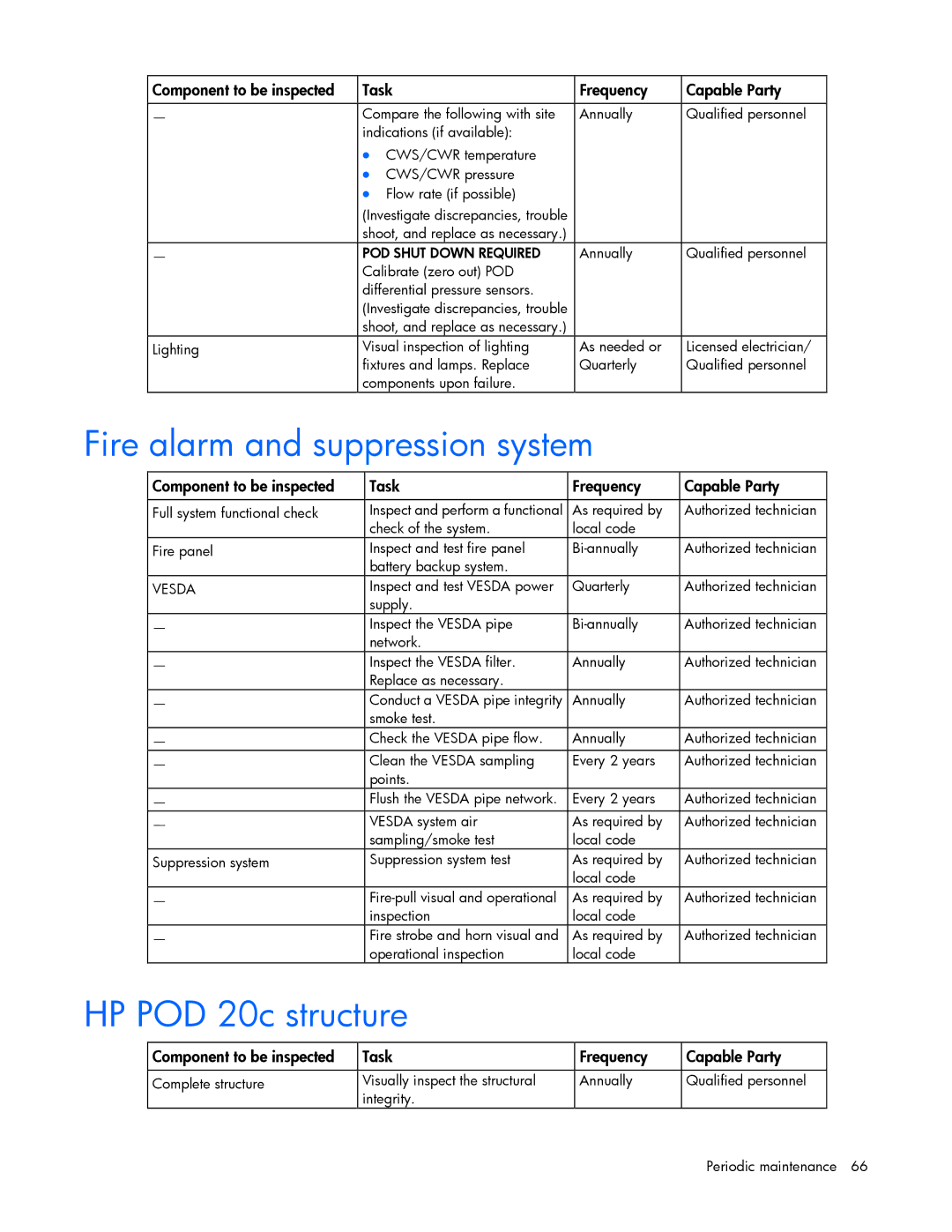

Component to be inspected | Task | Frequency | Capable Party | |

|

|

|

| |

— | Compare the following with site | Annually | Qualified personnel | |

| indications (if available): |

|

| |

| • | CWS/CWR temperature |

|

|

| • | CWS/CWR pressure |

|

|

| • Flow rate (if possible) |

|

| |

| (Investigate discrepancies, trouble |

|

| |

| shoot, and replace as necessary.) |

|

| |

— | POD SHUT DOWN REQUIRED | Annually | Qualified personnel | |

| Calibrate (zero out) POD |

|

| |

| differential pressure sensors. |

|

| |

| (Investigate discrepancies, trouble |

|

| |

| shoot, and replace as necessary.) |

|

| |

Lighting | Visual inspection of lighting | As needed or | Licensed electrician/ | |

| fixtures and lamps. Replace | Quarterly | Qualified personnel | |

| components upon failure. |

|

| |

Fire alarm and suppression system

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

Full system functional check | Inspect and perform a functional | As required by | Authorized technician |

| check of the system. | local code |

|

Fire panel | Inspect and test fire panel | Authorized technician | |

| battery backup system. |

|

|

VESDA | Inspect and test VESDA power | Quarterly | Authorized technician |

| supply. |

|

|

— | Inspect the VESDA pipe | Authorized technician | |

| network. |

|

|

— | Inspect the VESDA filter. | Annually | Authorized technician |

| Replace as necessary. |

|

|

— | Conduct a VESDA pipe integrity | Annually | Authorized technician |

| smoke test. |

|

|

— | Check the VESDA pipe flow. | Annually | Authorized technician |

— | Clean the VESDA sampling | Every 2 years | Authorized technician |

| points. |

|

|

— | Flush the VESDA pipe network. | Every 2 years | Authorized technician |

— | VESDA system air | As required by | Authorized technician |

| sampling/smoke test | local code |

|

Suppression system | Suppression system test | As required by | Authorized technician |

|

| local code |

|

— | As required by | Authorized technician | |

| inspection | local code |

|

— | Fire strobe and horn visual and | As required by | Authorized technician |

| operational inspection | local code |

|

HP POD 20c structure

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

|

|

Complete structure | Visually inspect the structural | Annually | Qualified personnel |

|

| integrity. |

|

|

|

|

|

| Periodic maintenance 66 | |