Lubrication

Accessories

Lubrication or other maintenance of optional equipment or accessories, see “Accessories” on page 55, is not described in this manual. This equipment too, naturally, requires maintenance. See the manuals for the respective accessories for instructions.

Lubricating in Accordance with the

Lubrication Schedule

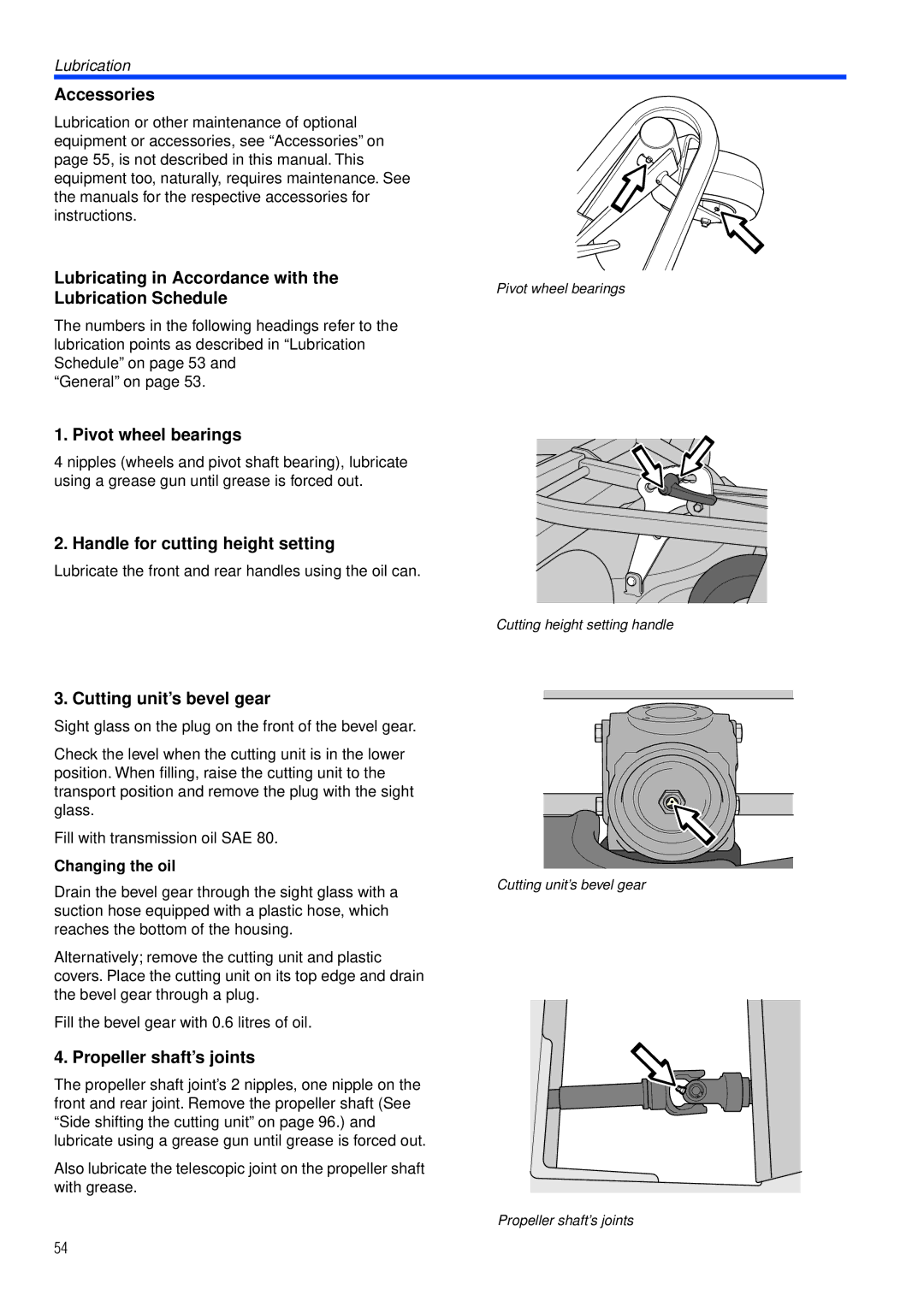

Pivot wheel bearings

The numbers in the following headings refer to the lubrication points as described in “Lubrication Schedule” on page 53 and

“General” on page 53.

1. Pivot wheel bearings

4 nipples (wheels and pivot shaft bearing), lubricate using a grease gun until grease is forced out.

2. Handle for cutting height setting

Lubricate the front and rear handles using the oil can.

Cutting height setting handle

3. Cutting unit’s bevel gear

Sight glass on the plug on the front of the bevel gear.

Check the level when the cutting unit is in the lower position. When filling, raise the cutting unit to the transport position and remove the plug with the sight glass.

Fill with transmission oil SAE 80.

Changing the oil

Drain the bevel gear through the sight glass with a suction hose equipped with a plastic hose, which reaches the bottom of the housing.

Alternatively; remove the cutting unit and plastic covers. Place the cutting unit on its top edge and drain the bevel gear through a plug.

Fill the bevel gear with 0.6 litres of oil.

4. Propeller shaft’s joints

The propeller shaft joint’s 2 nipples, one nipple on the front and rear joint. Remove the propeller shaft (See “Side shifting the cutting unit” on page 96.) and lubricate using a grease gun until grease is forced out.

Also lubricate the telescopic joint on the propeller shaft with grease.

Cutting unit’s bevel gear

Propeller shaft’s joints

54