Maintenance

Chapter 6: Maintenance

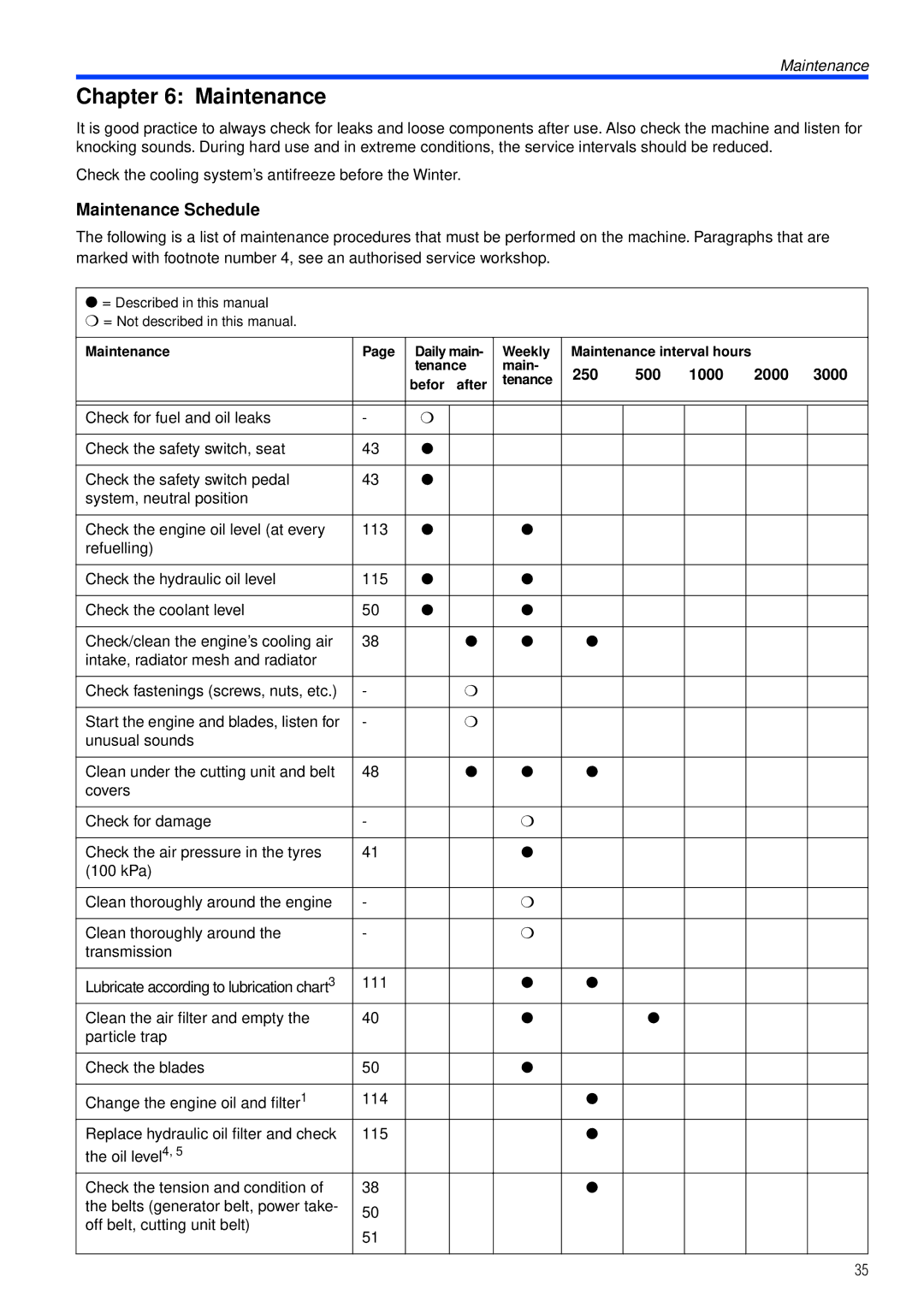

It is good practice to always check for leaks and loose components after use. Also check the machine and listen for knocking sounds. During hard use and in extreme conditions, the service intervals should be reduced.

Check the cooling system’s antifreeze before the Winter.

Maintenance Schedule

The following is a list of maintenance procedures that must be performed on the machine. Paragraphs that are marked with footnote number 4, see an authorised service workshop.

● = Described in this manual

❍ = Not described in this manual.

Maintenance | Page | Daily main- | Weekly | Maintenance interval hours |

|

| ||||

|

| tenance | main- | 250 | 500 | 1000 |

| 2000 3000 | ||

|

| befor after | tenance |

| ||||||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

Check for fuel and oil leaks | - | ❍ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the safety switch, seat | 43 | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the safety switch pedal | 43 | ● |

|

|

|

|

|

|

|

|

system, neutral position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the engine oil level (at every | 113 | ● |

| ● |

|

|

|

|

|

|

refuelling) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the hydraulic oil level | 115 | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the coolant level | 50 | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check/clean the engine’s cooling air | 38 |

| ● | ● | ● |

|

|

|

|

|

intake, radiator mesh and radiator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check fastenings (screws, nuts, etc.) | - |

| ❍ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start the engine and blades, listen for | - |

| ❍ |

|

|

|

|

|

|

|

unusual sounds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean under the cutting unit and belt | 48 |

| ● | ● | ● |

|

|

|

|

|

covers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check for damage | - |

|

| ❍ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the air pressure in the tyres | 41 |

|

| ● |

|

|

|

|

|

|

(100 kPa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean thoroughly around the engine | - |

|

| ❍ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean thoroughly around the | - |

|

| ❍ |

|

|

|

|

|

|

transmission |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricate according to lubrication chart3 | 111 |

|

| ● | ● |

|

|

|

|

|

Clean the air filter and empty the | 40 |

|

| ● |

| ● |

|

|

|

|

particle trap |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the blades | 50 |

|

| ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Change the engine oil and filter1 | 114 |

|

|

| ● |

|

|

|

|

|

Replace hydraulic oil filter and check | 115 |

|

|

| ● |

|

|

|

|

|

the oil level4, 5 |

|

|

|

|

|

|

|

|

|

|

Check the tension and condition of | 38 |

|

|

| ● |

|

|

|

|

|

the belts (generator belt, power take- | 50 |

|

|

|

|

|

|

|

|

|

off belt, cutting unit belt) |

|

|

|

|

|

|

|

|

| |

51 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

35