2.0INSTALLATION

2.1VENTILATION

Oil flooded rotary air compressors produce large amounts of heat. Because of this large heat production, the compressor must be placed in a room with adequate ventilation.

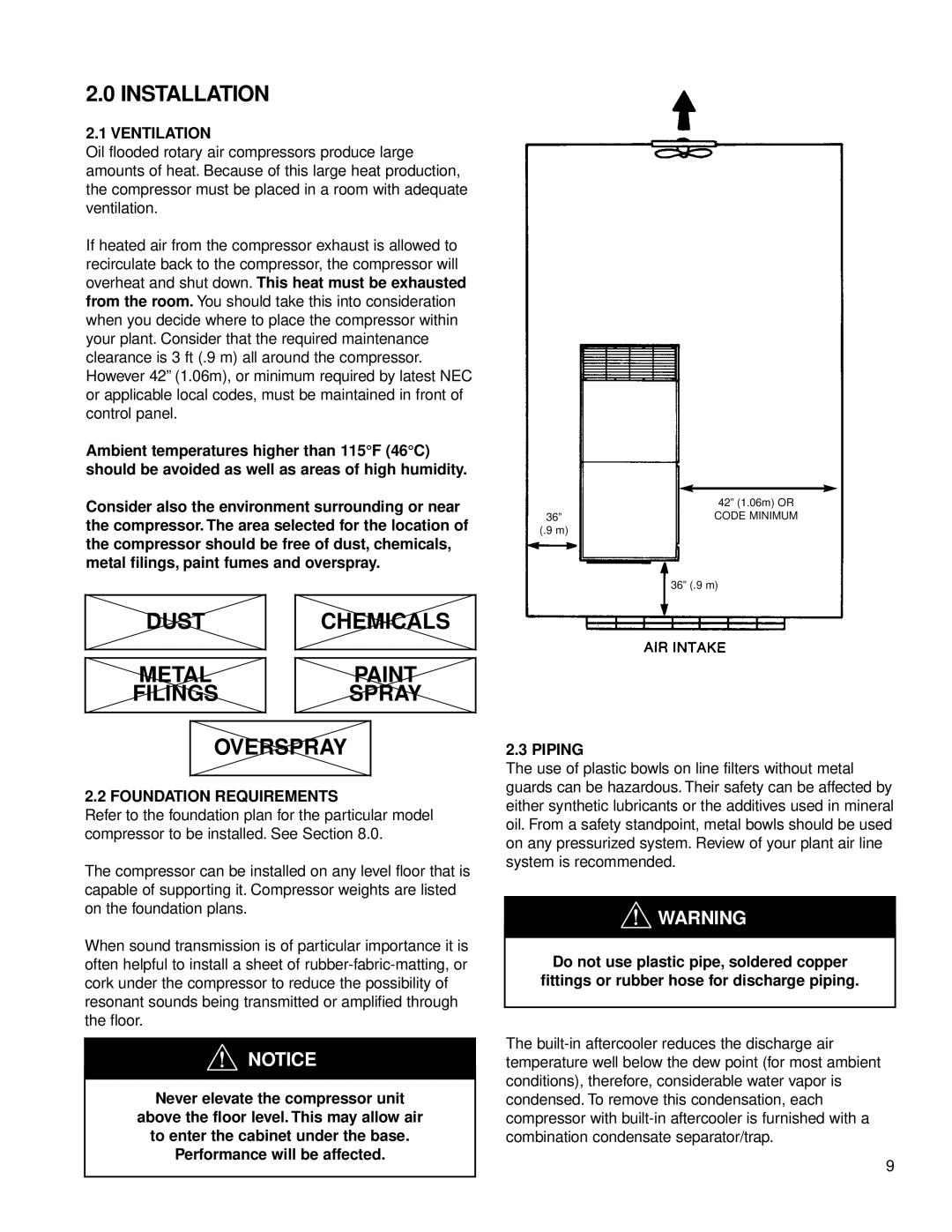

If heated air from the compressor exhaust is allowed to recirculate back to the compressor, the compressor will overheat and shut down. This heat must be exhausted from the room. You should take this into consideration when you decide where to place the compressor within your plant. Consider that the required maintenance clearance is 3 ft (.9 m) all around the compressor. However 42” (1.06m), or minimum required by latest NEC or applicable local codes, must be maintained in front of control panel.

Ambient temperatures higher than 115°F (46°C) should be avoided as well as areas of high humidity.

Consider also the environment surrounding or near the compressor. The area selected for the location of the compressor should be free of dust, chemicals, metal filings, paint fumes and overspray.

DUST | CHEMICALS |

METAL | PAINT |

FILINGS | SPRAY |

42” (1.06m) OR

36”CODE MINIMUM (.9 m)

36” (.9 m)

OVERSPRAY

2.2 FOUNDATION REQUIREMENTS

Refer to the foundation plan for the particular model compressor to be installed. See Section 8.0.

The compressor can be installed on any level floor that is capable of supporting it. Compressor weights are listed on the foundation plans.

When sound transmission is of particular importance it is often helpful to install a sheet of

NOTICE

Never elevate the compressor unit

above the floor level. This may allow air to enter the cabinet under the base.

Performance will be affected.

2.3 PIPING

The use of plastic bowls on line filters without metal guards can be hazardous. Their safety can be affected by either synthetic lubricants or the additives used in mineral oil. From a safety standpoint, metal bowls should be used on any pressurized system. Review of your plant air line system is recommended.

![]() WARNING

WARNING

Do not use plastic pipe, soldered copper fittings or rubber hose for discharge piping.

The

9