Power Supply Removal:

1)Open the starter box door.

2)Remove each

3)Remove the four screws holding the power supply to the starter plate, save them for mounting the replacement board, and remove the power supply.

4.14 COOLANT HOSES

The flexible hoses that carry coolant to and from the oil cooler may become brittle with age and will require replacement. Have your local

Ensure the compressor is isolated from the compressed air system by closing the isolation valve and venting pressure from the drip leg.

Ensure the main power disconnect switch is locked open and tagged.

REMOVAL

Remove enclosure panels.

Drain coolant into a clean container. Cover the container to prevent contamination. If the coolant is contaminated, a new charge of coolant must be used.

Hold fitting securely while removing hose.

INSTALLATION

Install the new hoses and reassemble the package by reversing the disassembly procedure. Start the compressor and check for leaks.

4.15 FLUID AND VIBRATION MONITORING

How does predictive analysis work? By establishing an initial baseline for normal operation, and then regularly monitoring fluid and vibration conditions, any sudden deviation or significant increase from this baseline can be identified and investigated to pinpoint the cause. More quickly diagnosing potential problems can directly save money by preventing costly failures and reducing or eliminating downtime. In addition, regular condition monitoring also helps to maximize the time between expensive preventative maintenance intervals, such as component rebuilds and coolant changes.

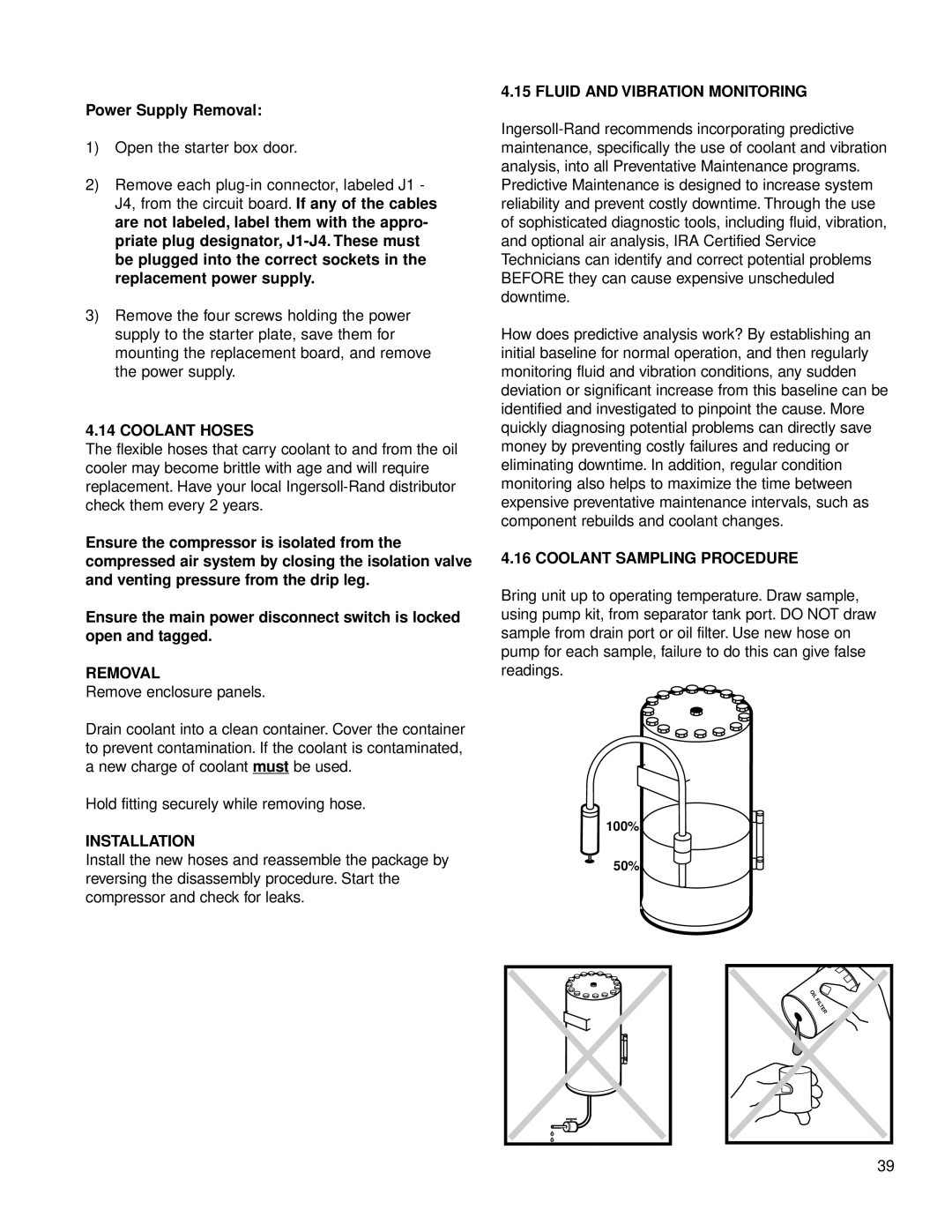

4.16 COOLANT SAMPLING PROCEDURE

Bring unit up to operating temperature. Draw sample, using pump kit, from separator tank port. DO NOT draw sample from drain port or oil filter. Use new hose on pump for each sample, failure to do this can give false readings.

100%

50%

39 |