110

110

110

110V

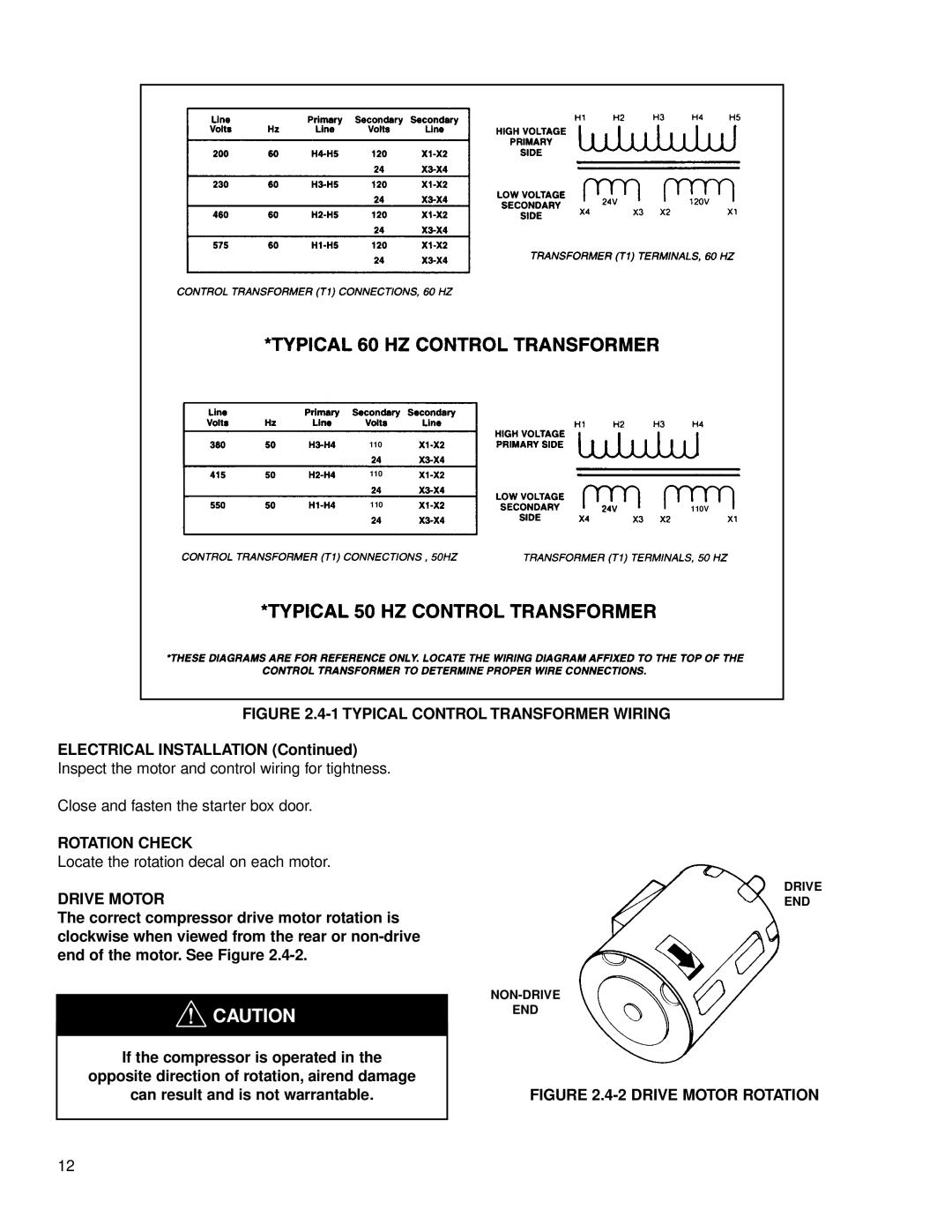

FIGURE 2.4-1 TYPICAL CONTROL TRANSFORMER WIRING

ELECTRICAL INSTALLATION (Continued) Inspect the motor and control wiring for tightness.

Close and fasten the starter box door.

ROTATION CHECK

Locate the rotation decal on each motor.

DRIVE MOTOR

The correct compressor drive motor rotation is clockwise when viewed from the rear or

![]() CAUTION

CAUTION

If the compressor is operated in the

opposite direction of rotation, airend damage

can result and is not warrantable.

DRIVE

END

END

FIGURE 2.4-2 DRIVE MOTOR ROTATION

12