3.5.1Lead/Lag- This setpoint is used for setting lead or lag operation. If set to lead, the controller will load and unload the compressor by the online and offline setpoints. If set to lag, the controller will subtract the lag offset (see 3.5.4) from the online and offline set points and operate the compressor at the lower pressure range.

3.5.2Offline Pressure- This setpoint is the pressure the compressor will unload at if it is operating in on/off line mode.

3.5.3Online Pressure- This setpoint is the pressure the compressor will load at.

3.5.4Lag Offset- This setpoint is used with the lead/lag operation. If the lead/lag set point is set to lag (see 3.5.1), the value of the lag offset will be subtracted from the online and offline setpoints.

3.5.5Mode of Operation- This setpoint is used to select the operating mode of the compressor. The choices are MOD/ACS, ON/OFF LINE, and MODULATION ONLY. See section 5.8 for more information on these operating modes.

3.5.6Max Modulation Pressure- This setpoint is the pressure the compressor will unload at if it is modulating. As the package discharge pressure rises toward this value, the inlet valve will start to close. The compressor will unload once the package discharge reaches this value. See section 5.8 for more information on modulation.

3.5.7Stop Delay Time- This setpoint is the minimum amount of time the compressor will run unloaded before stopping. This period does not apply to alarms (shutdowns).

3.5.8

3.5.9Contrast- This setpoint is used to improve the display on the Intellisys.

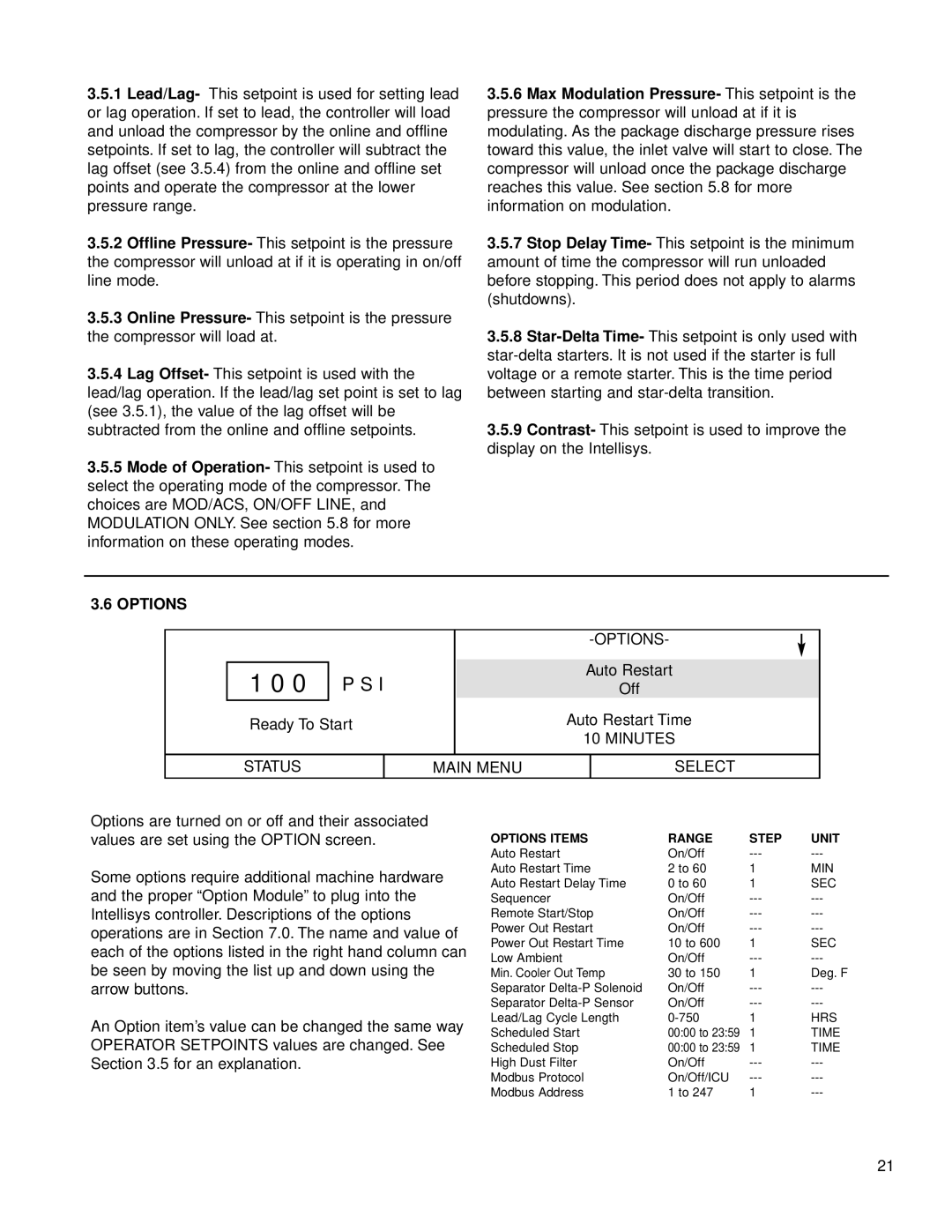

3.6 OPTIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 0 0 |

|

|

|

|

|

|

|

| Auto Restart | |||||

|

|

|

| P S I |

|

|

|

| Off | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| Auto Restart Time | |||||

|

|

|

|

|

| ||||||||||||

|

|

| Ready To Start |

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| 10 MINUTES | |||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STATUS |

|

|

|

|

|

| MAIN MENU |

|

| SELECT |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Options are turned on or off and their associated values are set using the OPTION screen.

Some options require additional machine hardware and the proper “Option Module” to plug into the Intellisys controller. Descriptions of the options operations are in Section 7.0. The name and value of each of the options listed in the right hand column can be seen by moving the list up and down using the arrow buttons.

An Option item’s value can be changed the same way OPERATOR SETPOINTS values are changed. See Section 3.5 for an explanation.

OPTIONS ITEMS | RANGE | STEP | UNIT |

Auto Restart | On/Off | ||

Auto Restart Time | 2 to 60 | 1 | MIN |

Auto Restart Delay Time | 0 to 60 | 1 | SEC |

Sequencer | On/Off | ||

Remote Start/Stop | On/Off | ||

Power Out Restart | On/Off | ||

Power Out Restart Time | 10 to 600 | 1 | SEC |

Low Ambient | On/Off | ||

Min. Cooler Out Temp | 30 to 150 | 1 | Deg. F |

Separator | On/Off | ||

Separator | On/Off | ||

Lead/Lag Cycle Length | 1 | HRS | |

Scheduled Start | 00:00 to 23:59 | 1 | TIME |

Scheduled Stop | 00:00 to 23:59 | 1 | TIME |

High Dust Filter | On/Off | ||

Modbus Protocol | On/Off/ICU | ||

Modbus Address | 1 to 247 | 1 |

21