4.4 INLET AIR FILTER

To check condition of the inlet filter, run compressor in the LOADED mode and observe “Inlet Filter” on the CURRENT STATUS display screen. If the display says “Inlet Filter OK”, then no maintenance is required. If “ ? ” is flashing on the screen and the display says “CHANGE INLET FILTER”, then the inlet filter should be changed.

To change inlet filter elements, loosen wing nut on top of inlet filter housing. Lift cover up and away to expose element/s.

Carefully remove the old element/s to prevent dirt from entering the inlet valve. Discard old element/s.

Thoroughly clean the element housing and wipe all surfaces.

Install new element/s and inspect to ensure that they have seated properly.

Install top of inlet filter housing.

Inspect the rubber seal on the retainer wing nut and replace seal if required.

Tighten wing nut.

Start machine and run in the load mode to verify filter condition.

4.5 COOLANT FILTER

To check the condition of the coolant filter, the compressor must be running. Observe “Injected Temperature” on the CURRENT STATUS display screen. If the temperature is less than 120°F (49°C), continue to run the machine. When the temperature is greater than 120°F (49°C), observe “Coolant Filter” on the screen. If the display says “Coolant Filter OK”, then the filter does not need service. If “ ? ” is flashing on the screen and the display says “CHANGE COOLANT FILTER”, then the filter should be replaced.

Use a suitable device and loosen the old element. Use drain pan to catch any leakage during removal. Discard old element.

Wipe the sealing surface of the filter with a clean,

Remove the replacement element from its protective package. Apply a small amount of clean lubricant on the rubber seal and install the element.

Screw element/s on until the seal makes contact with the head of the filter assembly. Tighten approximately

Start unit and check for leaks.

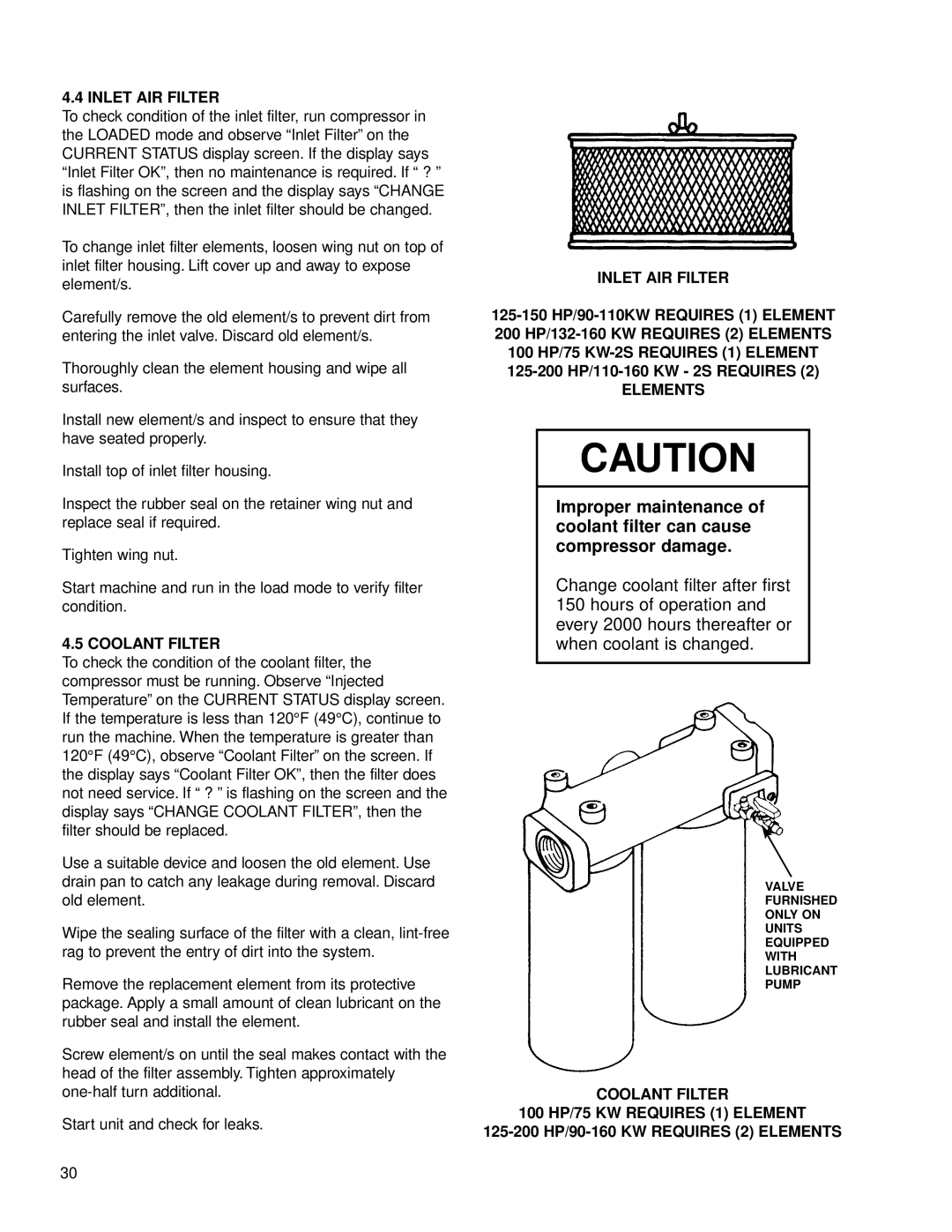

INLET AIR FILTER

200 HP/132-160 KW REQUIRES (2) ELEMENTS

100 HP/75

ELEMENTS

CAUTION

Improper maintenance of coolant filter can cause compressor damage.

Change coolant filter after first 150 hours of operation and every 2000 hours thereafter or when coolant is changed.

VALVE

FURNISHED

ONLY ON

UNITS

EQUIPPED

WITH

LUBRICANT

PUMP

COOLANT FILTER

100 HP/75 KW REQUIRES (1) ELEMENT

30