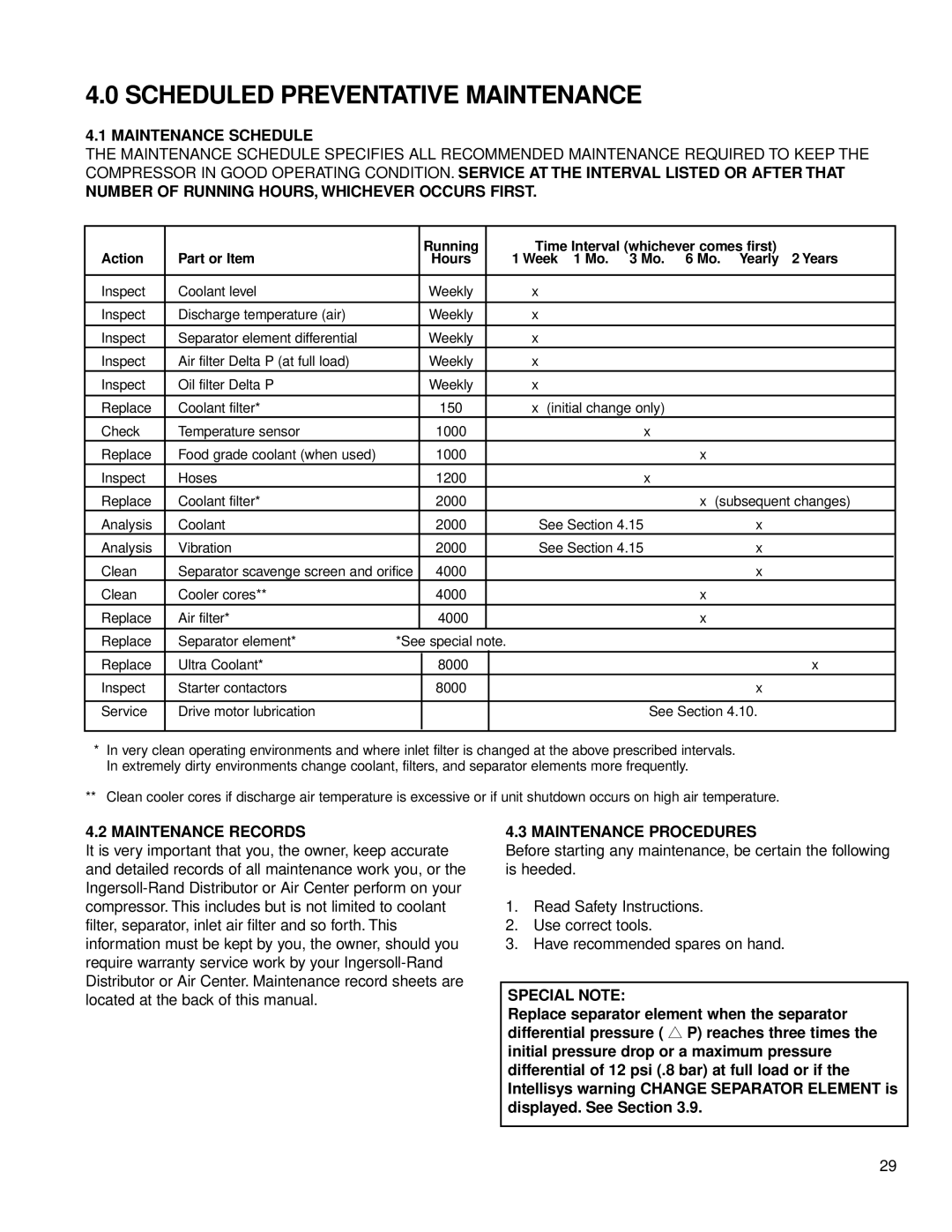

4.0SCHEDULED PREVENTATIVE MAINTENANCE

4.1MAINTENANCE SCHEDULE

THE MAINTENANCE SCHEDULE SPECIFIES ALL RECOMMENDED MAINTENANCE REQUIRED TO KEEP THE COMPRESSOR IN GOOD OPERATING CONDITION. SERVICE AT THE INTERVAL LISTED OR AFTER THAT

NUMBER OF RUNNING HOURS, WHICHEVER OCCURS FIRST.

Action | Part or Item |

|

| Running |

| Time Interval (whichever comes first) | |

|

| Hours |

| 1 Week 1 Mo. 3 Mo. | 6 Mo. Yearly 2 Years | ||

|

|

|

|

|

|

|

|

Inspect | Coolant level |

|

| Weekly |

| x |

|

|

|

|

|

|

|

|

|

Inspect | Discharge temperature (air) |

|

| Weekly |

| x |

|

|

|

|

|

|

|

|

|

Inspect | Separator element differential |

|

| Weekly |

| x |

|

Inspect | Air filter Delta P (at full load) |

|

| Weekly |

| x |

|

Inspect | Oil filter Delta P |

|

| Weekly |

| x |

|

|

|

|

|

|

|

|

|

Replace | Coolant filter* |

| 150 |

| x (initial change only) |

| |

Check | Temperature sensor |

| 1000 |

| x |

| |

Replace | Food grade coolant (when used) |

| 1000 |

|

| x | |

Inspect | Hoses |

| 1200 |

| x |

| |

Replace | Coolant filter* |

| 2000 |

|

| x (subsequent changes) | |

Analysis | Coolant |

| 2000 |

| See Section 4.15 | x | |

Analysis | Vibration |

| 2000 |

| See Section 4.15 | x | |

Clean | Separator scavenge screen and orifice | 4000 |

|

| x | ||

Clean | Cooler cores** |

| 4000 |

|

| x | |

Replace | Air filter* |

| 4000 |

|

| x | |

|

|

|

|

|

|

|

|

Replace | Separator element* | *See special note. |

|

| |||

Replace | Ultra Coolant* |

| 8000 |

|

| x | |

Inspect | Starter contactors |

| 8000 |

|

| x | |

|

|

|

|

|

|

| |

Service | Drive motor lubrication |

|

|

|

| See Section 4.10. | |

|

|

|

|

|

|

|

|

*In very clean operating environments and where inlet filter is changed at the above prescribed intervals. In extremely dirty environments change coolant, filters, and separator elements more frequently.

**Clean cooler cores if discharge air temperature is excessive or if unit shutdown occurs on high air temperature.

4.2 MAINTENANCE RECORDS

It is very important that you, the owner, keep accurate and detailed records of all maintenance work you, or the

4.3 MAINTENANCE PROCEDURES

Before starting any maintenance, be certain the following is heeded.

1.Read Safety Instructions.

2.Use correct tools.

3.Have recommended spares on hand.

SPECIAL NOTE:

Replace separator element when the separator differential pressure ( ▲ P) reaches three times the initial pressure drop or a maximum pressure differential of 12 psi (.8 bar) at full load or if the Intellisys warning CHANGE SEPARATOR ELEMENT is displayed. See Section 3.9.

29