Two types of dryers, refrigerated or desiccant, are used to correct moisture related problems in a compressed air system. Refrigerated dryers are normally specified where compressed air pressure dew points of 33°F (1°C) to 39°F (4°C) are adequate. Desiccant dryers are required where pressure dew points must be below 33°F (1°C).

Contact your local

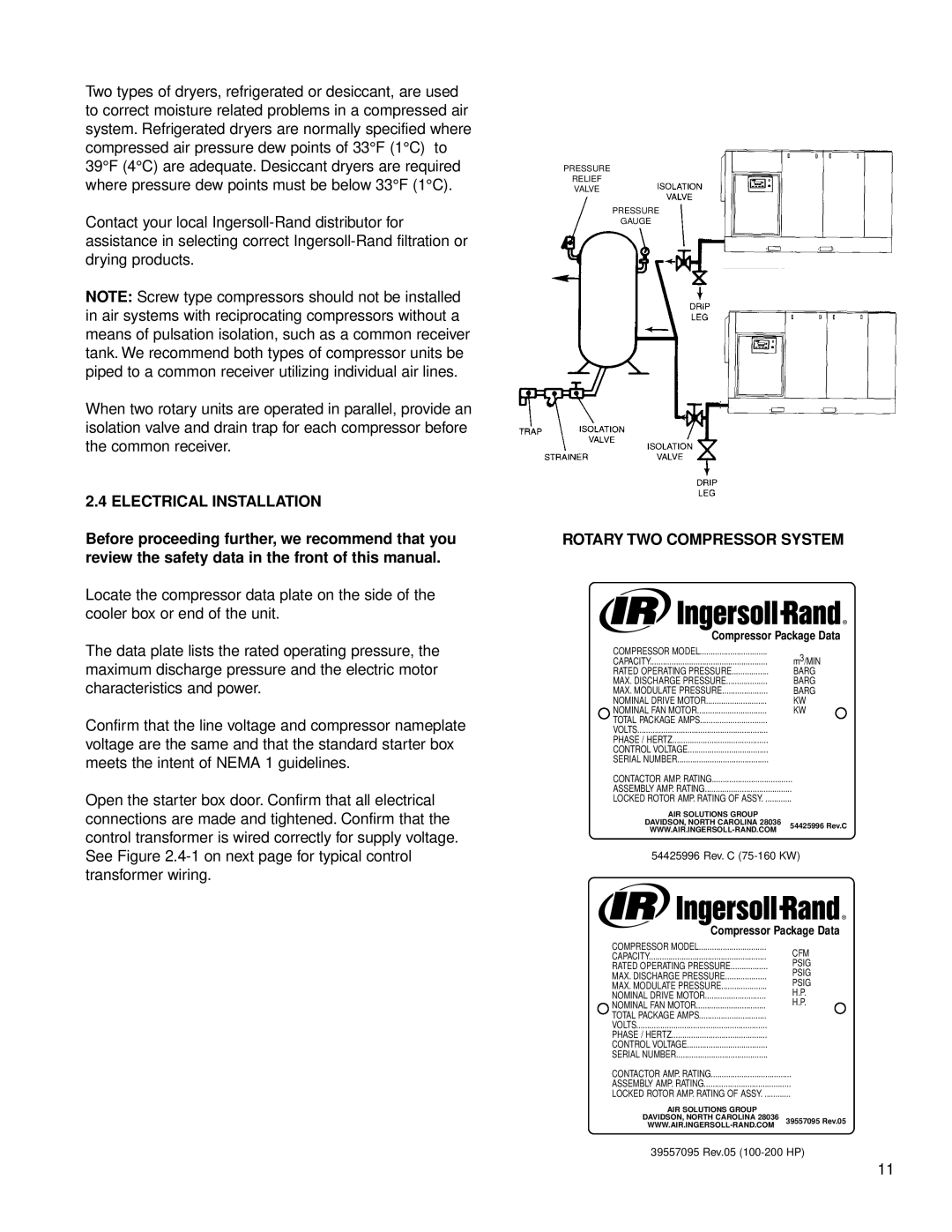

NOTE: Screw type compressors should not be installed in air systems with reciprocating compressors without a means of pulsation isolation, such as a common receiver tank. We recommend both types of compressor units be piped to a common receiver utilizing individual air lines.

When two rotary units are operated in parallel, provide an isolation valve and drain trap for each compressor before the common receiver.

2.4 ELECTRICAL INSTALLATION

Before proceeding further, we recommend that you review the safety data in the front of this manual.

Locate the compressor data plate on the side of the cooler box or end of the unit.

The data plate lists the rated operating pressure, the maximum discharge pressure and the electric motor characteristics and power.

Confirm that the line voltage and compressor nameplate voltage are the same and that the standard starter box meets the intent of NEMA 1 guidelines.

Open the starter box door. Confirm that all electrical connections are made and tightened. Confirm that the control transformer is wired correctly for supply voltage. See Figure

PRESSURE

RELIEF

VALVE

PRESSURE

GAUGE

ROTARY TWO COMPRESSOR SYSTEM

Compressor Package Data

COMPRESSOR MODEL | m3/MIN |

CAPACITY | |

RATED OPERATING PRESSURE | BARG |

MAX. DISCHARGE PRESSURE | BARG |

MAX. MODULATE PRESSURE | BARG |

NOMINAL DRIVE MOTOR | KW |

NOMINAL FAN MOTOR | KW |

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP. RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

AIR SOLUTIONS GROUP

DAVIDSON, NORTH CAROLINA 28036 54425996 Rev.C

54425996 Rev. C

Compressor Package Data

COMPRESSOR MODEL | CFM | |

CAPACITY | ||

PSIG | ||

RATED OPERATING PRESSURE | ||

PSIG | ||

MAX. DISCHARGE PRESSURE | ||

PSIG | ||

MAX. MODULATE PRESSURE | ||

H.P. | ||

NOMINAL DRIVE MOTOR | ||

H.P. | ||

NOMINAL FAN MOTOR |

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP. RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

AIR SOLUTIONS GROUP

DAVIDSON, NORTH CAROLINA 28036 39557095 Rev.05

39557095 Rev.05

11