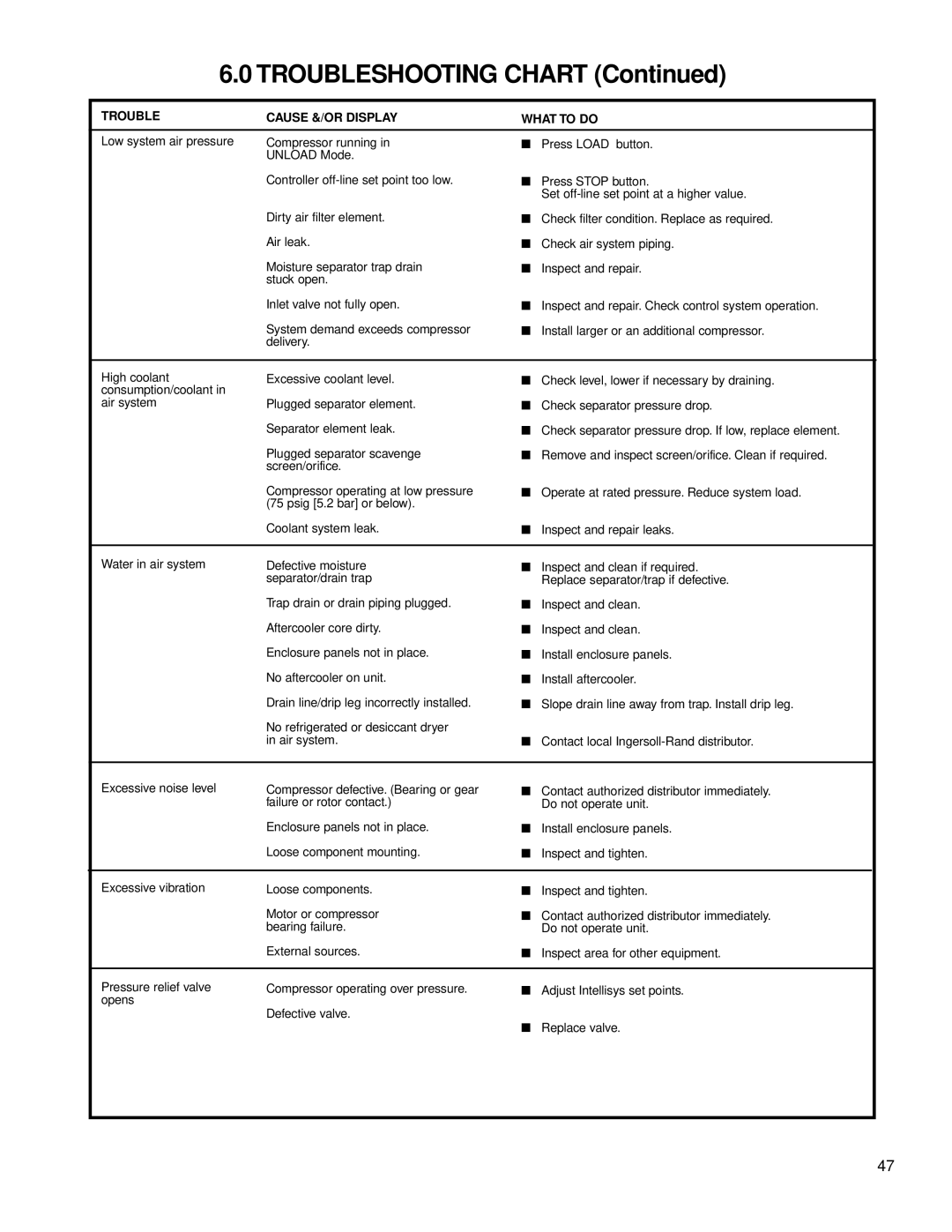

6.0 TROUBLESHOOTING CHART (Continued)

|

|

|

|

|

|

|

|

| TROUBLE |

| CAUSE &/OR DISPLAY |

|

|

| |

|

|

| WHAT TO DO |

| |||

|

|

|

|

|

|

|

|

| Low system air pressure |

| Compressor running in |

| ■ | Press LOAD button. |

|

|

|

| UNLOAD Mode. |

|

|

|

|

|

|

| Controller |

| ■ | Press STOP button. |

|

|

|

|

|

|

| Set |

|

|

|

| Dirty air filter element. |

| ■ Check filter condition. Replace as required. |

| |

|

|

| Air leak. |

| ■ Check air system piping. |

| |

|

|

| Moisture separator trap drain |

| ■ | Inspect and repair. |

|

|

|

| stuck open. |

|

|

|

|

|

|

| Inlet valve not fully open. |

| ■ Inspect and repair. Check control system operation. |

| |

|

|

| System demand exceeds compressor |

| ■ Install larger or an additional compressor. |

| |

|

|

| delivery. |

|

|

|

|

|

|

|

|

|

|

| |

| High coolant |

| Excessive coolant level. |

| ■ Check level, lower if necessary by draining. |

| |

| consumption/coolant in |

|

|

|

|

|

|

| air system |

| Plugged separator element. |

| ■ Check separator pressure drop. |

| |

|

|

| Separator element leak. |

| ■ Check separator pressure drop. If low, replace element. |

| |

|

|

| Plugged separator scavenge |

| ■ | Remove and inspect screen/orifice. Clean if required. |

|

|

|

| screen/orifice. |

|

|

|

|

|

|

| Compressor operating at low pressure |

| ■ Operate at rated pressure. Reduce system load. |

| |

|

|

| (75 psig [5.2 bar] or below). |

|

|

|

|

|

|

| Coolant system leak. |

| ■ Inspect and repair leaks. |

| |

|

|

|

|

|

|

| |

| Water in air system |

| Defective moisture |

| ■ Inspect and clean if required. |

| |

|

|

| separator/drain trap |

|

| Replace separator/trap if defective. |

|

|

|

| Trap drain or drain piping plugged. |

| ■ | Inspect and clean. |

|

|

|

| Aftercooler core dirty. |

| ■ | Inspect and clean. |

|

|

|

| Enclosure panels not in place. |

| ■ | Install enclosure panels. |

|

|

|

| No aftercooler on unit. |

| ■ | Install aftercooler. |

|

|

|

| Drain line/drip leg incorrectly installed. |

| ■ | Slope drain line away from trap. Install drip leg. |

|

|

|

| No refrigerated or desiccant dryer |

|

|

|

|

|

|

| in air system. |

| ■ Contact local |

| |

|

|

|

|

|

|

| |

| Excessive noise level |

| Compressor defective. (Bearing or gear |

| ■ Contact authorized distributor immediately. |

| |

|

|

| failure or rotor contact.) |

|

| Do not operate unit. |

|

|

|

| Enclosure panels not in place. |

| ■ | Install enclosure panels. |

|

|

|

| Loose component mounting. |

| ■ | Inspect and tighten. |

|

|

|

|

|

|

|

|

|

| Excessive vibration |

| Loose components. |

| ■ | Inspect and tighten. |

|

|

|

| Motor or compressor |

| ■ Contact authorized distributor immediately. |

| |

|

|

| bearing failure. |

|

| Do not operate unit. |

|

|

|

| External sources. |

| ■ Inspect area for other equipment. |

| |

|

|

|

|

|

|

| |

| Pressure relief valve |

| Compressor operating over pressure. |

| ■ Adjust Intellisys set points. |

| |

| opens |

| Defective valve. |

|

|

|

|

|

|

|

|

| Replace valve. |

| |

|

|

|

|

| ■ |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

47