Stabilizers

To obtain the best quality embroidery, it is important to use stabilizers.

Types of stabilizer

Water Soluble Stabilizer will dissolve in water. Use this stabilizer for cutwork or lace embroidery, and also for the right side of looped fabrics such as towel to avoid loops coming through the embroidery.

Sticky Stabilizer is a sticky paper used for securing a small fabric or work that cannot be secured in the hoop. It is also used for velvet and other napped fabric that would be permanently marked by the hoop.

Usage:

The stabilizer should be attached to the wrong side of fabric. More than one layer may be required.

Felt or stable fabrics do not need to be stabilized and you may embroider directly on it. For firm fabrics, you may place a thin paper under the fabric.

The

Cut the stabilizer larger than the embroidery hoop and set it on the hoop so that the entire piece is fastened with the hoop to prevent looseness of the fabric.

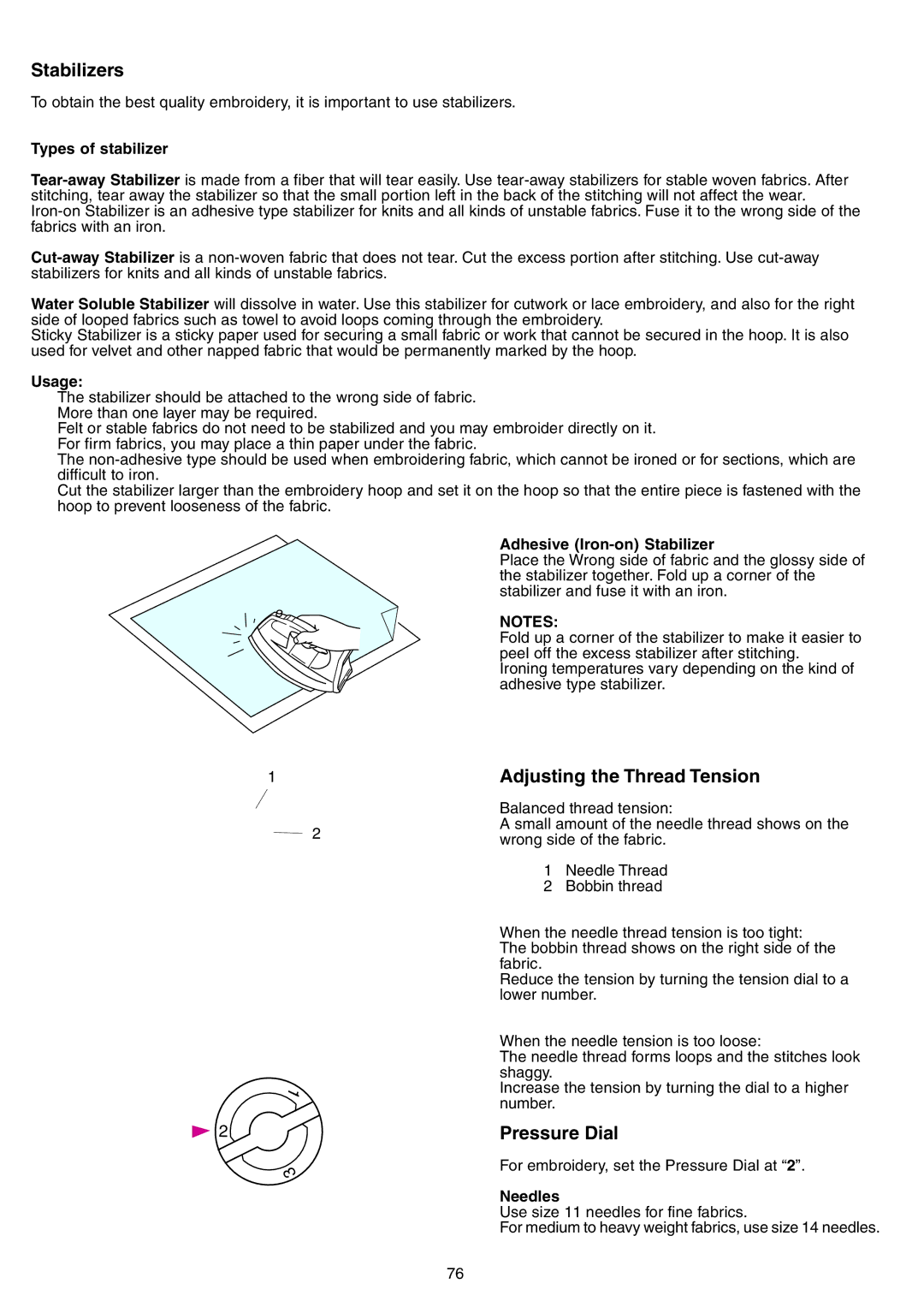

Adhesive (Iron-on) Stabilizer

Place the Wrong side of fabric and the glossy side of the stabilizer together. Fold up a corner of the stabilizer and fuse it with an iron.

NOTES:

Fold up a corner of the stabilizer to make it easier to peel off the excess stabilizer after stitching.

Ironing temperatures vary depending on the kind of adhesive type stabilizer.

1 |

| Adjusting the Thread Tension | |

|

| Balanced thread tension: | |

| 2 | A small amount of the needle thread shows on the | |

| wrong side of the fabric. | ||

|

| ||

|

| 1 | Needle Thread |

|

| 2 | Bobbin thread |

1

2

3

When the needle thread tension is too tight: The bobbin thread shows on the right side of the fabric.

Reduce the tension by turning the tension dial to a lower number.

When the needle tension is too loose:

The needle thread forms loops and the stitches look shaggy.

Increase the tension by turning the dial to a higher number.

Pressure Dial

For embroidery, set the Pressure Dial at “2”.

Needles

Use size 11 needles for fine fabrics.

For medium to heavy weight fabrics, use size 14 needles.

76