System Operations

![]() IMPORTANT

IMPORTANT

Some scroll compressor have internal vacuum protector that will unload scrolls when suction pressure goes below 20 psig. A hissing sound will be heard when the compressor is running unloaded. Protector will reset when low pressure in system is raised above 40 psig. DO NOT REPLACE COMPRESSOR.

The heat pump control (A175) provides the following functions:

SDemand defrost algorithm

SField−selectable defrost termination temperatures

SInternal switching of outputs

SCompressor anti−short−cycle delay.

SFive strikes lockout safety function

SHigh (S4) and low (S87) pressure switches

SAmbient (RT13), and coil temperatures (RT21) temperature monitoring and protection.

COMPRESSOR ANTI−SHORT CYCLE DELAY

The heat pump control protects the compressor from:

SShort cycling (five minutes) when there is initial power up

SInterruption in power to the unit

SPressure or sensor trips

SDelay after Y1 demand is removed.

In non−communicating systems the delay is set for 300 seconds (five minutes) and can not be changed. To override timer when active or inactive, place a jumper on the field test pins between 1 and 2 seconds.

In communicating system, the icomfort Touch® thermostat has a separate built−in 5−minute non−adjustable short cycle protection.

Resetting Anti−Short Cycle Delay

The FIELD TEST pins (E33) on the heat pump control can be jumpered between 1 to 2 seconds to bypass delay.

HIGH (S4) AND LOW (S87) PRESSURE SWITCHES

The unit’s pressure switches (LO PS − S87 and HI PS − S4) are factory−wired into the heat pump control on the LO−PS and HI−PS terminals, respectively.

Low Pressure Switch (LO−PS) for low pressure switch sequence of operation.

High Pressure Switch (HI−PS) for high pressure switch sequence of operation.

Pressure Switch Event Settings

The following pressures are the auto reset event value triggers for low and high pressure thresholds:

SHigh Pressure (auto reset) − trip at 590 psig; reset at 418.

SLow Pressure (auto reset) − trip at 25 psig; reset at 40.

COMPRESSOR PROTECTION

LOCKOUT SAFETY FUNCTION

The five−strike lockout safety function is designed to protect the unit’s compressor from damage. The five−strike feature is used for high pressure (S4) and low (S87) pressure switch trips and W input fault or miswire.

Resetting Five−Strike Lockout

Once the condition has been rectified, power to the heat pump control’s R terminal must be cycled OFF, or a jumper placed on the FIELD TEST pins between 1− to 2−seconds to reset the heat pump control.

Defrost System

The heat pump control (A175) measures differential temperatures to detect when the system is performing poorly because of ice build−up on the outdoor coil. The controller self−calibrates (see figure 26) when the defrost system starts and after each system defrost cycle. The heat pump control monitors ambient temperature, outdoor coil temperature, and total run−time to determine when a defrost cycle is required. The coil temperature sensor is designed with a spring clip to allow mounting to the outside coil tubing. The location of the coil sensor is important for proper defrost operation (see figure 1 for location of coil sensor).

NOTE − The heat pump control accurately measures the performance of the system as frost accumulates on the outdoor coil. This typically will translate into longer running time between defrost cycles as more frost accumulates on the outdoor coil before the heat pump control initiates defrost cycles.

DEFROST OPERATING MODES

The heat pump control board has three operational modes which are:

SDefrost calibration and operation (see figure 26)

SDefrost test (see figure 27)

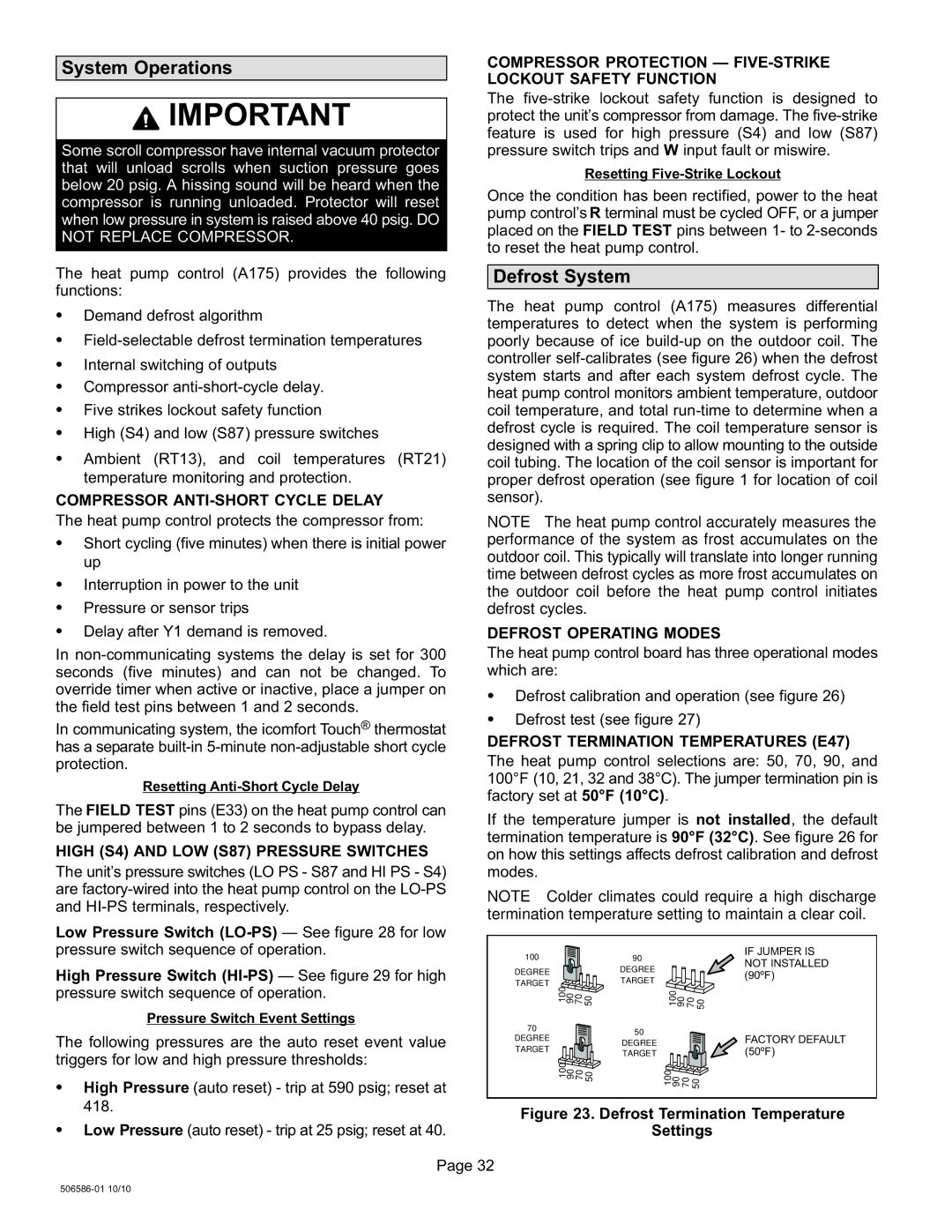

DEFROST TERMINATION TEMPERATURES (E47) The heat pump control selections are: 50, 70, 90, and 100°F (10, 21, 32 and 38°C). The jumper termination pin is factory set at 50°F (10°C).

If the temperature jumper is not installed, the default termination temperature is 90°F (32°C). See figure 26 for on how this settings affects defrost calibration and defrost modes.

NOTE − Colder climates could require a high discharge termination temperature setting to maintain a clear coil.

100 |

| 90 |

| IF JUMPER IS |

|

| NOT INSTALLED | ||

DEGREE |

| DEGREE |

| |

|

| (90ºF) | ||

| TARGET |

| ||

TARGET |

|

| ||

|

|

| ||

100 |

|

| 100 |

|

90 | 50 | 50 | ||

| 70 | 90 70 | ||

70 |

| 50 |

|

|

DEGREE |

|

| FACTORY DEFAULT | |

| DEGREE |

| ||

TARGET |

|

| ||

| TARGET |

| (50ºF) | |

|

|

| ||

100 |

| 50 | 100 |

|

90 70 | 90 70 50 | |||

Figure 23. Defrost Termination Temperature

Settings

Page 32

506586−01 10/10