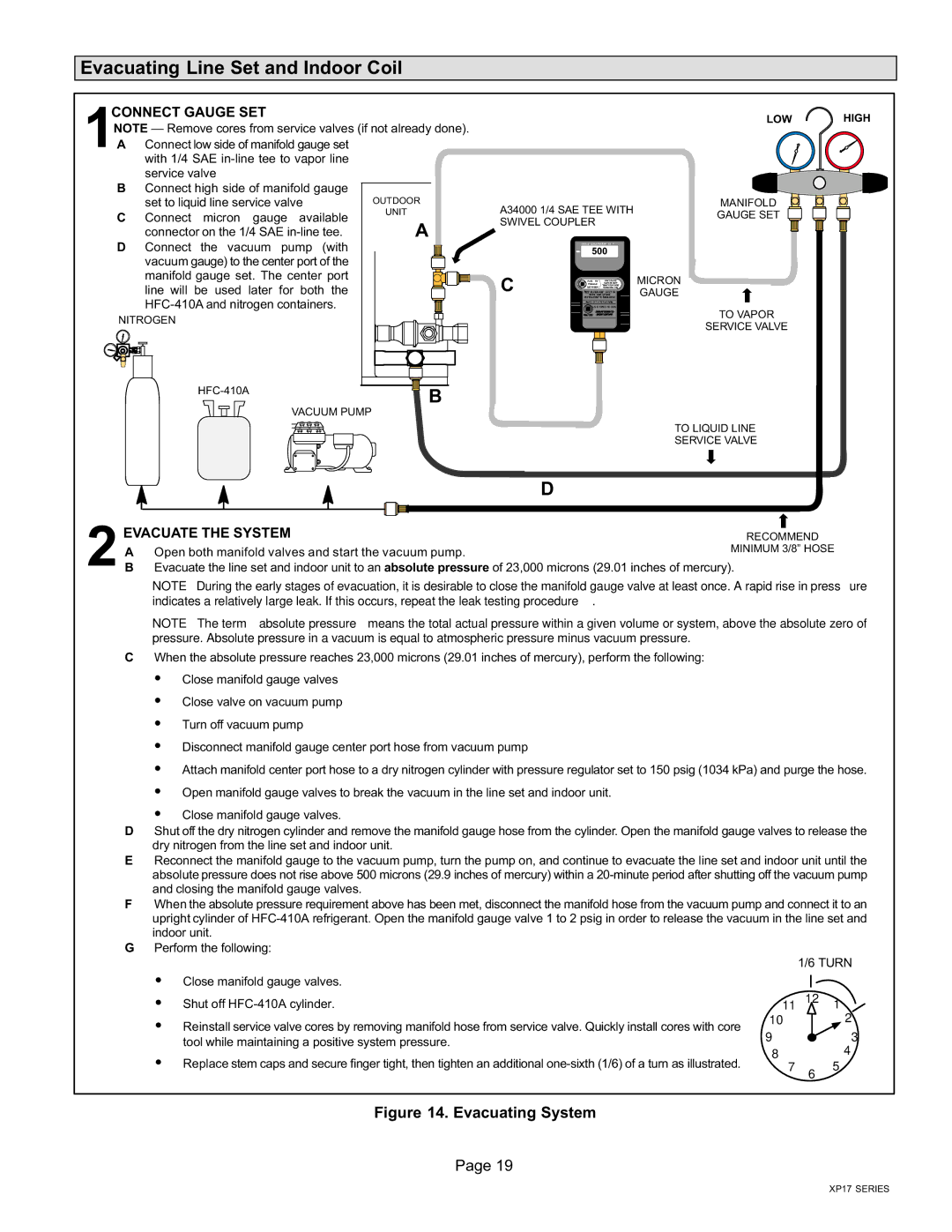

Evacuating Line Set and Indoor Coil

CONNECT GAUGE SET

1NOTEA Connect low side of manifold gauge set with 1/4 SAE in−line tee to vapor line service valve

B Connect high side of manifold gauge |

| |||||

| set to liquid line service valve | OUTDOOR | ||||

C | Connect | micron | gauge | available | UNIT | |

A | ||||||

| connector on the 1/4 SAE in−line tee. | |||||

D Connect | the vacuum pump (with |

| ||||

| vacuum gauge) to the center port of the |

| ||||

| manifold gauge set. The center port |

| ||||

A34000 1/4 SAE TEE WITH SWIVEL COUPLER

500

LOW HIGH

MANIFOLD

GAUGE SET

line will be used later for both the |

|

HFC−410A and nitrogen containers. |

|

NITROGEN |

|

HFC−410A | B |

| |

VACUUM PUMP |

|

C![]()

![]() MICRON

MICRON

![]()

![]()

![]() GAUGE

GAUGE

TO VAPOR

SERVICE VALVE

TO LIQUID LINE

SERVICE VALVE

|

|

|

|

|

|

| D |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

EVACUATE THE SYSTEM | RECOMMEND | ||||||||

A Open both manifold valves and start the vacuum pump. | MINIMUM 3/8" HOSE | ||||||||

|

| ||||||||

2 B Evacuate the line set and indoor unit to an absolute pressure of 23,000 microns (29.01 inches of mercury). | |||||||||

| NOTE |

|

|

|

|

|

|

| ure |

| indicates a relatively large leak. If this occurs, repeat the leak testing procedure. |

|

| ||||||

| NOTE | absolute pressure means the total actual pressure within a given volume or system, above the absolute zero of | |||||||

pressure. Absolute pressure in a vacuum is equal to atmospheric pressure minus vacuum pressure.

CWhen the absolute pressure reaches 23,000 microns (29.01 inches of mercury), perform the following:

S S S S S S

Close manifold gauge valves

Close valve on vacuum pump

Turn off vacuum pump

Disconnect manifold gauge center port hose from vacuum pump

Attach manifold center port hose to a dry nitrogen cylinder with pressure regulator set to 150 psig (1034 kPa) and purge the hose.

Open manifold gauge valves to break the vacuum in the line set and indoor unit.

SClose manifold gauge valves.

DShut off the dry nitrogen cylinder and remove the manifold gauge hose from the cylinder. Open the manifold gauge valves to release the dry nitrogen from the line set and indoor unit.

EReconnect the manifold gauge to the vacuum pump, turn the pump on, and continue to evacuate the line set and indoor unit until the absolute pressure does not rise above 500 microns (29.9 inches of mercury) within a 20−minute period after shutting off the vacuum pump and closing the manifold gauge valves.

FWhen the absolute pressure requirement above has been met, disconnect the manifold hose from the vacuum pump and connect it to an upright cylinder of HFC−410A refrigerant. Open the manifold gauge valve 1 to 2 psig in order to release the vacuum in the line set and indoor unit.

GPerform the following:

1/6 TURN

SClose manifold gauge valves.

SShut off HFC−410A cylinder.

SReinstall service valve cores by removing manifold hose from service valve. Quickly install cores with core tool while maintaining a positive system pressure.

SReplace stem caps and secure finger tight, then tighten an additional one−sixth (1/6) of a turn as illustrated.

11 | 12 | 1 |

10 |

| 2 |

9 |

| 3 |

84

7 6 5

Figure 14. Evacuating System

Page 19

XP17 SERIES