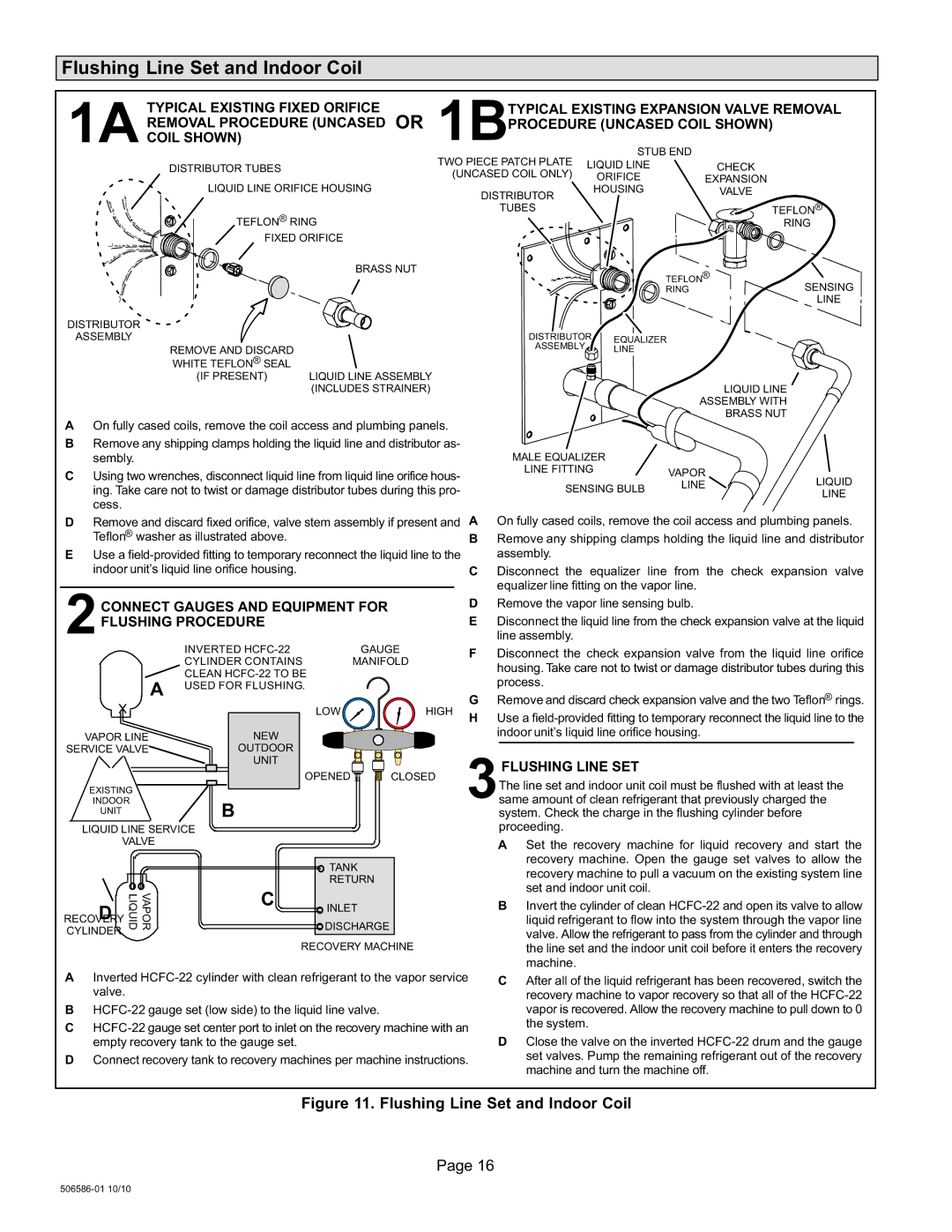

Flushing Line Set and Indoor Coil

TYPICAL EXISTING FIXED ORIFICE | TYPICAL EXISTING EXPANSION VALVE REMOVAL | |||

REMOVAL PROCEDURE (UNCASED | OR 1BPROCEDURE (UNCASED COIL SHOWN) | |||

1A COIL SHOWN) | ||||

|

| STUB END |

| |

DISTRIBUTOR TUBES | TWO PIECE PATCH PLATE | LIQUID LINE | CHECK | |

(UNCASED COIL ONLY) | ||||

| ORIFICE | EXPANSION | ||

LIQUID LINE ORIFICE HOUSING |

| |||

DISTRIBUTOR | HOUSING | VALVE | ||

|

|

| ||

TEFLON® RING | TUBES |

| TEFLON® | |

|

| RING | ||

FIXED ORIFICE |

|

|

| |

BRASS NUT

DISTRIBUTOR ASSEMBLY

REMOVE AND DISCARD

WHITE TEFLON® SEAL

(IF PRESENT) LIQUID LINE ASSEMBLY (INCLUDES STRAINER)

AOn fully cased coils, remove the coil access and plumbing panels.

BRemove any shipping clamps holding the liquid line and distributor as- sembly.

CUsing two wrenches, disconnect liquid line from liquid line orifice hous- ing. Take care not to twist or damage distributor tubes during this pro- cess.

TEFLON®

RINGSENSING

LINE

DISTRIBUTOR EQUALIZER

ASSEMBLY![]() LINE

LINE

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

MALE EQUALIZER |

|

| |

LINE FITTING | VAPOR |

| |

| LIQUID | ||

SENSING BULB | LINE | ||

LINE | |||

| |||

|

|

DRemove and discard fixed orifice, valve stem assembly if present and Teflon® washer as illustrated above.

EUse a field−provided fitting to temporary reconnect the liquid line to the indoor unit’s liquid line orifice housing.

AOn fully cased coils, remove the coil access and plumbing panels.

BRemove any shipping clamps holding the liquid line and distributor assembly.

CDisconnect the equalizer line from the check expansion valve equalizer line fitting on the vapor line.

2CONNECT GAUGES AND EQUIPMENT FOR FLUSHING PROCEDURE

DRemove the vapor line sensing bulb.

EDisconnect the liquid line from the check expansion valve at the liquid line assembly.

INVERTED HCFC−22 | GAUGE |

CYLINDER CONTAINS | MANIFOLD |

CLEAN HCFC−22 TO BE |

|

A USED FOR FLUSHING. |

|

1 | LOW | HIGH |

VAPOR LINE | NEW |

SERVICE VALVE | OUTDOOR |

| UNIT |

OPENED ![]()

![]()

![]()

![]()

![]()

![]()

![]() CLOSED

CLOSED

EXISTING

INDOOR

UNITB

LIQUID LINE SERVICE

VALVE

|

|

| TANK |

|

|

| RETURN |

| VAPOR LIQUID | C | DISCHARGE |

D |

|

| INLET |

RECOVERY |

|

|

|

CYLINDER |

|

|

|

|

|

| RECOVERY MACHINE |

FDisconnect the check expansion valve from the liquid line orifice housing. Take care not to twist or damage distributor tubes during this process.

GRemove and discard check expansion valve and the two Teflon® rings.

HUse a field−provided fitting to temporary reconnect the liquid line to the indoor unit’s liquid line orifice housing.

3FLUSHING LINE SET

The line set and indoor unit coil must be flushed with at least the same amount of clean refrigerant that previously charged the system. Check the charge in the flushing cylinder before proceeding.

ASet the recovery machine for liquid recovery and start the recovery machine. Open the gauge set valves to allow the recovery machine to pull a vacuum on the existing system line set and indoor unit coil.

BInvert the cylinder of clean HCFC−22 and open its valve to allow liquid refrigerant to flow into the system through the vapor line valve. Allow the refrigerant to pass from the cylinder and through the line set and the indoor unit coil before it enters the recovery machine.

AInverted HCFC−22 cylinder with clean refrigerant to the vapor service valve.

BHCFC−22 gauge set (low side) to the liquid line valve.

CHCFC−22 gauge set center port to inlet on the recovery machine with an empty recovery tank to the gauge set.

DConnect recovery tank to recovery machines per machine instructions.

CAfter all of the liquid refrigerant has been recovered, switch the recovery machine to vapor recovery so that all of the HCFC−22 vapor is recovered. Allow the recovery machine to pull down to 0 the system.

DClose the valve on the inverted HCFC−22 drum and the gauge set valves. Pump the remaining refrigerant out of the recovery machine and turn the machine off.

Figure 11. Flushing Line Set and Indoor Coil

Page 16

506586−01 10/10