Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION

CONTROLS AND SETTINGS

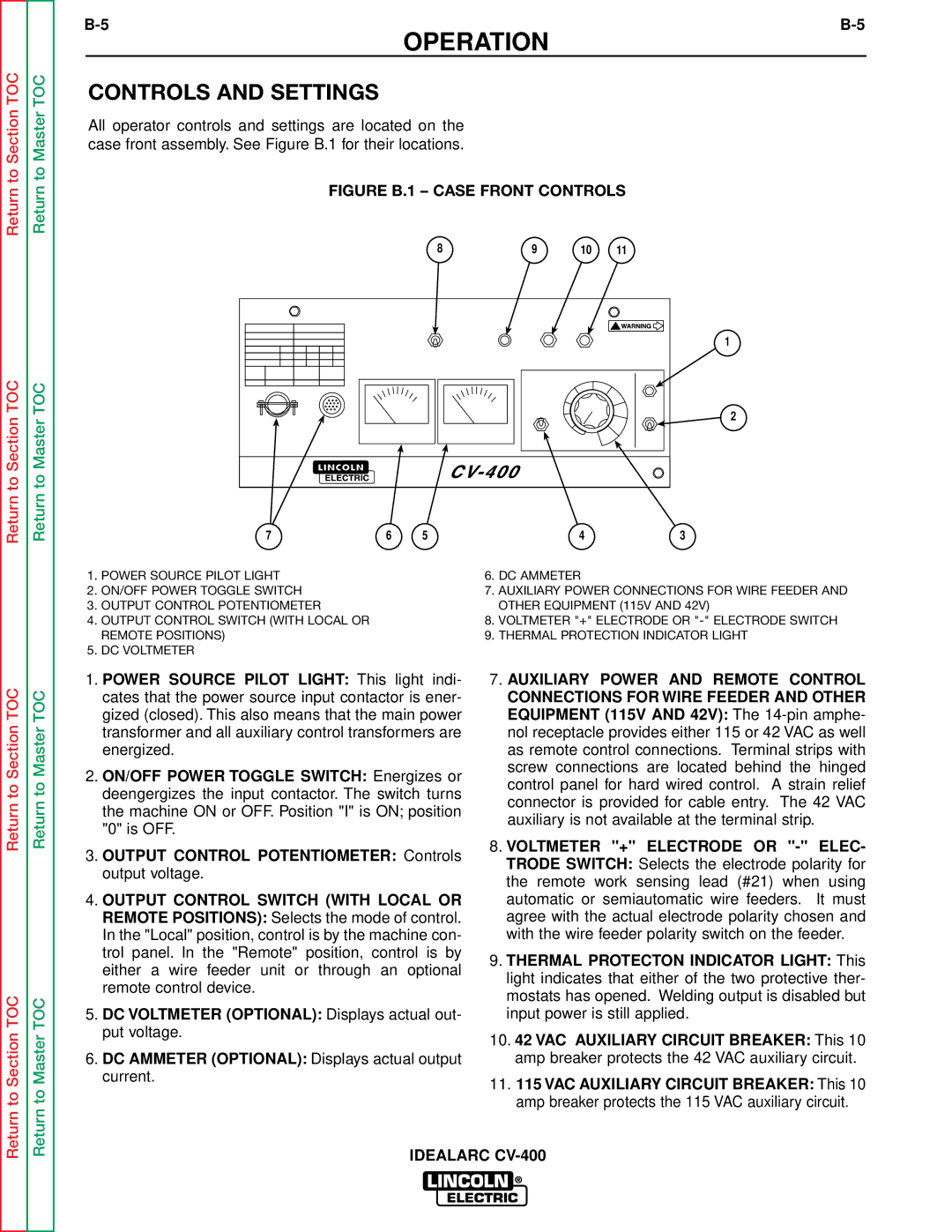

All operator controls and settings are located on the case front assembly. See Figure B.1 for their locations.

FIGURE B.1 – CASE FRONT CONTROLS

|

| 8 | 9 | 10 | 11 |

|

|

|

|

| 1 |

|

|

|

|

| 2 |

7 | 6 | 5 |

| 4 | 3 |

1. POWER SOURCE PILOT LIGHT | 6. DC AMMETER |

2. ON/OFF POWER TOGGLE SWITCH | 7. AUXILIARY POWER CONNECTIONS FOR WIRE FEEDER AND |

3. OUTPUT CONTROL POTENTIOMETER | OTHER EQUIPMENT (115V AND 42V) |

4. OUTPUT CONTROL SWITCH (WITH LOCAL OR | 8. VOLTMETER "+" ELECTRODE OR |

REMOTE POSITIONS) | 9. THERMAL PROTECTION INDICATOR LIGHT |

5. DC VOLTMETER |

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.POWER SOURCE PILOT LIGHT: This light indi- cates that the power source input contactor is ener- gized (closed). This also means that the main power transformer and all auxiliary control transformers are energized.

2.ON/OFF POWER TOGGLE SWITCH: Energizes or deengergizes the input contactor. The switch turns the machine ON or OFF. Position "I" is ON; position "0" is OFF.

3.OUTPUT CONTROL POTENTIOMETER: Controls output voltage.

4.OUTPUT CONTROL SWITCH (WITH LOCAL OR REMOTE POSITIONS): Selects the mode of control. In the "Local" position, control is by the machine con- trol panel. In the "Remote" position, control is by either a wire feeder unit or through an optional remote control device.

5.DC VOLTMETER (OPTIONAL): Displays actual out- put voltage.

6.DC AMMETER (OPTIONAL): Displays actual output current.

7.AUXILIARY POWER AND REMOTE CONTROL CONNECTIONS FOR WIRE FEEDER AND OTHER EQUIPMENT (115V AND 42V): The

8.VOLTMETER "+" ELECTRODE OR

9.THERMAL PROTECTON INDICATOR LIGHT: This light indicates that either of the two protective ther- mostats has opened. Welding output is disabled but input power is still applied.

10.42 VAC AUXILIARY CIRCUIT BREAKER: This 10 amp breaker protects the 42 VAC auxiliary circuit.

11.115 VAC AUXILIARY CIRCUIT BREAKER: This 10 amp breaker protects the 115 VAC auxiliary circuit.

IDEALARC