Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

TROUBLESHOOTING & REPAIR

SCR/DIODE RECTIFIER ASSEMBLY

REMOVAL AND REPLACEMENT (continued)

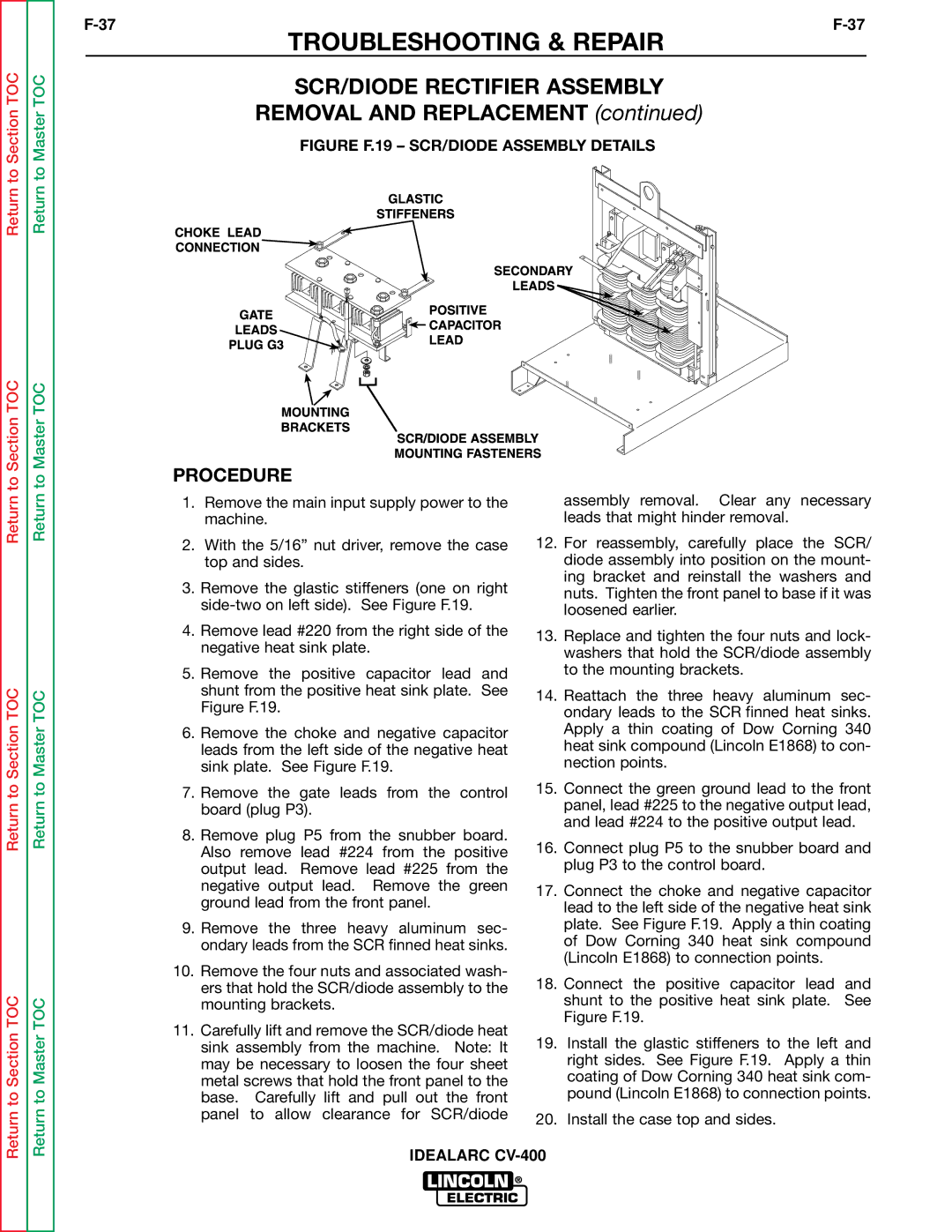

FIGURE F.19 – SCR/DIODE ASSEMBLY DETAILS

PROCEDURE

Return

Return to Section TOC

Return to Section TOC

Return

Return to Master TOC

Return to Master TOC

1.Remove the main input supply power to the machine.

2.With the 5/16” nut driver, remove the case top and sides.

3.Remove the glastic stiffeners (one on right

4.Remove lead #220 from the right side of the negative heat sink plate.

5.Remove the positive capacitor lead and shunt from the positive heat sink plate. See Figure F.19.

6.Remove the choke and negative capacitor leads from the left side of the negative heat sink plate. See Figure F.19.

7.Remove the gate leads from the control board (plug P3).

8.Remove plug P5 from the snubber board. Also remove lead #224 from the positive output lead. Remove lead #225 from the negative output lead. Remove the green ground lead from the front panel.

9.Remove the three heavy aluminum sec- ondary leads from the SCR finned heat sinks.

10.Remove the four nuts and associated wash- ers that hold the SCR/diode assembly to the mounting brackets.

11.Carefully lift and remove the SCR/diode heat sink assembly from the machine. Note: It may be necessary to loosen the four sheet metal screws that hold the front panel to the base. Carefully lift and pull out the front panel to allow clearance for SCR/diode

assembly removal. Clear any necessary leads that might hinder removal.

12.For reassembly, carefully place the SCR/ diode assembly into position on the mount- ing bracket and reinstall the washers and nuts. Tighten the front panel to base if it was loosened earlier.

13.Replace and tighten the four nuts and lock- washers that hold the SCR/diode assembly to the mounting brackets.

14.Reattach the three heavy aluminum sec- ondary leads to the SCR finned heat sinks. Apply a thin coating of Dow Corning 340 heat sink compound (Lincoln E1868) to con- nection points.

15.Connect the green ground lead to the front panel, lead #225 to the negative output lead, and lead #224 to the positive output lead.

16.Connect plug P5 to the snubber board and plug P3 to the control board.

17.Connect the choke and negative capacitor lead to the left side of the negative heat sink plate. See Figure F.19. Apply a thin coating of Dow Corning 340 heat sink compound (Lincoln E1868) to connection points.

18.Connect the positive capacitor lead and shunt to the positive heat sink plate. See Figure F.19.

19.Install the glastic stiffeners to the left and right sides. See Figure F.19. Apply a thin coating of Dow Corning 340 heat sink com- pound (Lincoln E1868) to connection points.

20.Install the case top and sides.