Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

MAIN TRANSFORMER (T1) VOLTAGE TEST (continued)

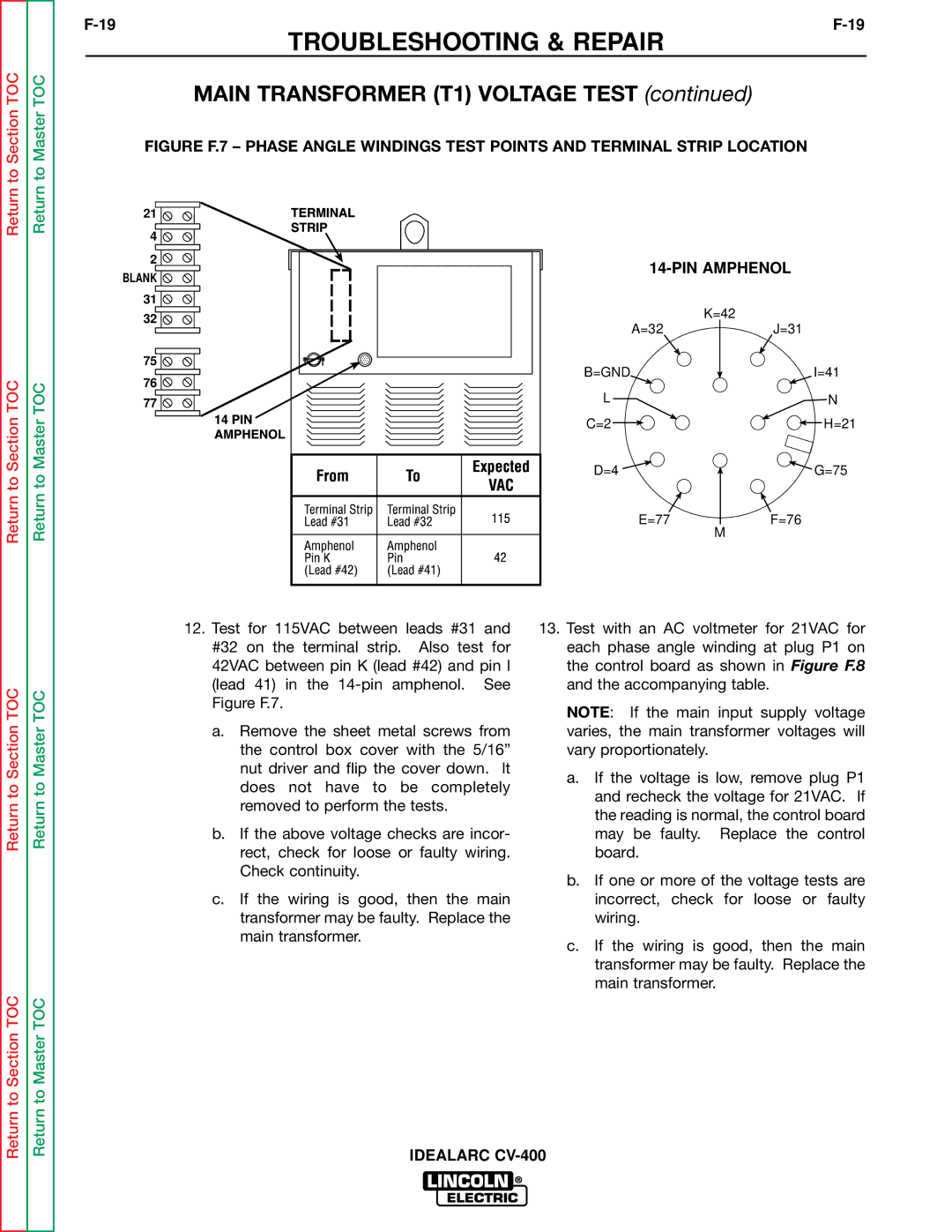

FIGURE F.7 – PHASE ANGLE WINDINGS TEST POINTS AND TERMINAL STRIP LOCATION

21 |

|

| |

4 |

|

| |

2 |

| ||

BLANK | |||

|

| ||

31 |

| K=42 | |

32 |

| ||

A=32 | J=31 | ||

| |||

75 | B=GND | I=41 | |

76 | |||

|

| ||

77 | L | N | |

| C=2 | H=21 | |

| D=4 | G=75 | |

| E=77 | F=76 | |

|

| M | |

Return to Section TOC

Return to Master TOC

12.Test for 115VAC between leads #31 and #32 on the terminal strip. Also test for 42VAC between pin K (lead #42) and pin I (lead 41) in the

a.Remove the sheet metal screws from the control box cover with the 5/16” nut driver and flip the cover down. It does not have to be completely removed to perform the tests.

b.If the above voltage checks are incor- rect, check for loose or faulty wiring. Check continuity.

c.If the wiring is good, then the main transformer may be faulty. Replace the main transformer.

13.Test with an AC voltmeter for 21VAC for each phase angle winding at plug P1 on the control board as shown in Figure F.8 and the accompanying table.

NOTE: If the main input supply voltage varies, the main transformer voltages will vary proportionately.

a.If the voltage is low, remove plug P1 and recheck the voltage for 21VAC. If the reading is normal, the control board may be faulty. Replace the control board.

b.If one or more of the voltage tests are incorrect, check for loose or faulty wiring.

c.If the wiring is good, then the main transformer may be faulty. Replace the main transformer.

Return to Section TOC

Return to Master TOC