Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

STATIC SCR/DIODE RECTIFIER BRIDGE TEST (continued)

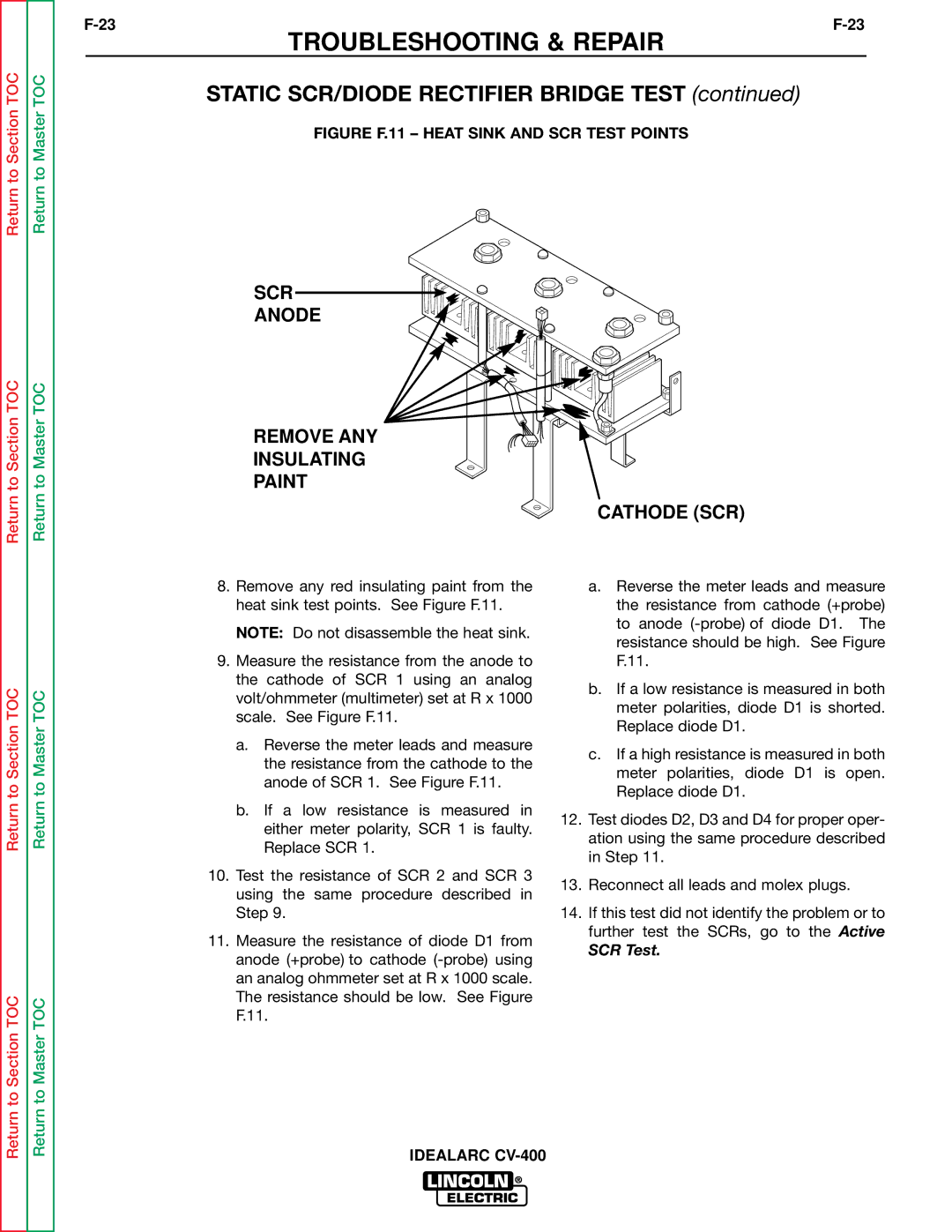

FIGURE F.11 – HEAT SINK AND SCR TEST POINTS

SCR

ANODE

REMOVE ANY

INSULATING

PAINT

CATHODE (SCR)

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

8.Remove any red insulating paint from the heat sink test points. See Figure F.11.

NOTE: Do not disassemble the heat sink.

9.Measure the resistance from the anode to the cathode of SCR 1 using an analog volt/ohmmeter (multimeter) set at R x 1000 scale. See Figure F.11.

a.Reverse the meter leads and measure the resistance from the cathode to the anode of SCR 1. See Figure F.11.

b.If a low resistance is measured in either meter polarity, SCR 1 is faulty. Replace SCR 1.

10.Test the resistance of SCR 2 and SCR 3 using the same procedure described in Step 9.

11.Measure the resistance of diode D1 from anode (+probe) to cathode

a.Reverse the meter leads and measure the resistance from cathode (+probe) to anode

b.If a low resistance is measured in both meter polarities, diode D1 is shorted. Replace diode D1.

c.If a high resistance is measured in both meter polarities, diode D1 is open. Replace diode D1.

12.Test diodes D2, D3 and D4 for proper oper- ation using the same procedure described in Step 11.

13.Reconnect all leads and molex plugs.

14.If this test did not identify the problem or to further test the SCRs, go to the Active

SCR Test.